0433-INS-400

Rev.

E

6-21

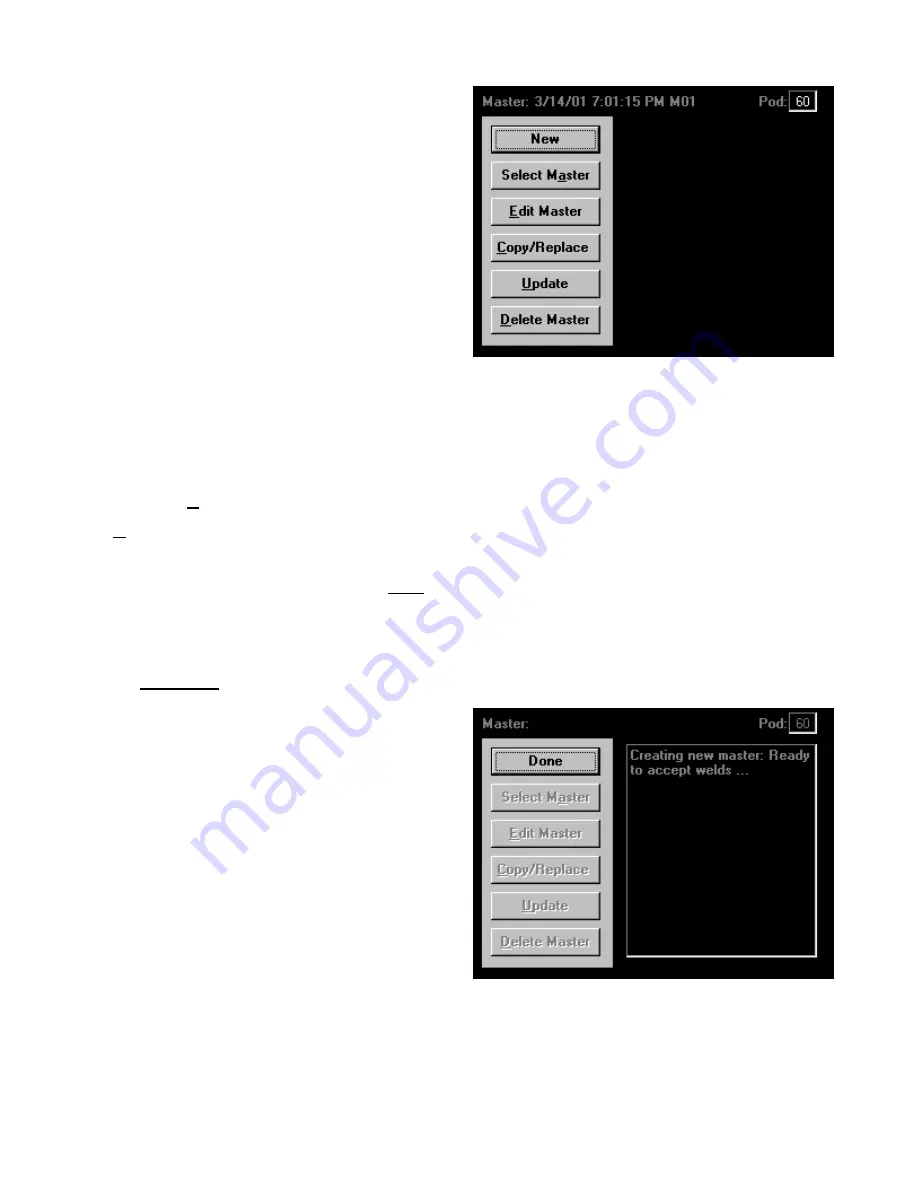

Mastering Screen

In order to be sure that production welds are good,

it must be verified that the parameters of each weld

match the parameters of a known good weld. A

master

is made from a weld or welds which are

proven to be good through destructive testing. The

master is the average of all parameters for these

welds. The general procedure for creating a master

is as follows:

Note:

Individual applications may have different

procedures for creating masters. If this is the case,

you should create masters according to the

procedure specific to your application.

1. Press the

New

button. Using the same weld schedule and bin select, make several of the same type

of weld, marking the weld number on each workpiece.

2. Press the

Done

button. Destructively test all of the welds made during mastering.

3. Using the

Edit Master

option, delete any welds from the master that failed destructive testing.

4.

Update

the master. New welds will now be compared to the known good welds in the master.

Note:

Using different bin selects, multiple masters can be made at the same time. For more

information about, refer to Chapter 9, FAQ.

The

Mastering

options are described below. Some option buttons will be disabled (text shown fuzzy)

during the mastering process, or if no masters exist for the selected POD / ID.

•

New/Done

This option button starts and ends the mastering

process. Once the

New

button is pressed, the

screen reads

Initializing master memory…

The button text then changes to

Done

and the

screen reads

Creating new master: Ready to

accept welds…

Once you have finished adding

welds to the master, use the

Done

button to end

the mastering process.

When the

Done

button is pressed, the software

calculates a master from the average of the

welds that were included in the master. The

Master ID (name) defaults to be the current

date and time. When the master is complete, by

default it will be broken up into three segments:

Segment 0

–

Pre Weld

(before current starts)

Segment 1

–

Weld

(portion of weld with current)

Segment 2

–

Post Weld

(after current stops)

Figure

6-35

Mastering screen

Figure

6-36

Creating a master

Summary of Contents for WELDWISE 2400

Page 1: ...Revision C 001 User s Manual WeldWise 2400 THE WELD MONITORING SPECIALISTS TM...

Page 2: ......

Page 34: ...4 6...

Page 46: ...5 12...

Page 94: ...6 48...

Page 104: ...7 10...

Page 116: ...9 4...

Page 146: ...10 30...

Page 164: ...0340 DWG 400 Rev C 11 18...

Page 165: ...0308 DWG 400 Rev D 11 19...

Page 168: ...11 22...

Page 176: ...0454 APP 118 Rev A 12 6...

Page 194: ...13 2...