Service Training

Section

2.4

Page

14

2.4.1.7

INSTALLING THE STEERING AXLE

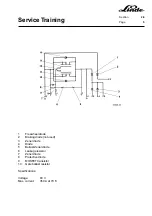

- Put two rubber axle blocks (10) on the centre axle.

- Install the steering axle (11) with the axle blocks (10) in the counterweight (3) from below, raise it slightly

until the axle blocks contact the counterweight and safely support it.

- Lead both hydraulic hoses through the counterweight into the battery compartment.

- Lead the steering sensor cables into the counterweight.

- Coat the steering fastening screws (8) with Loctite 243.

- Secure the two plates (9) and rubber axle mounts (10) with the screws (8).

- Torque the screws (8) to 195 Nm.

- On trucks without the higher driver’s seat, install the additional weight (4) in the counterweight from below

and safely support it.

- Install the first fastening screw (2) through the hole for the trailer coupling pin.

NOTE:

On trucks from series 10/94, the mounting bolt (2) can be accessed from below at the ballast

weight (4).

- Install the second fastening screw (7) along with the plate (6).

- Tighten both screws.

- Connect the two steering cylinder hose lines to the appropriate pipelines.

- Connect the proximity switch connectors X6 and X7.

- Install the battery.

- Eliminate any air in the steering by operating the steering wheel through 10 complete travel cycles.

- Check the oil level in the oil reservoir and add oil, if necessary.

- Remount the wheels.

- Lower the truck to the ground.

- Torque opposite wheel bolts to 180 Nm.

Summary of Contents for 336 Series

Page 2: ......

Page 8: ...ServiceTraining ...

Page 12: ...ServiceTraining Section 2 1 Page 4 ...

Page 14: ...ServiceTraining Section 2 1 Page 6 2 1 4 TRACTIONMOTORDISASSEMBLY ...

Page 19: ...ServiceTraining Section 2 2 Page 3 ...

Page 21: ...ServiceTraining Section 2 2 Page 5 ...

Page 27: ...ServiceTraining Section 2 2 Page 11 ...

Page 28: ...ServiceTraining Section 2 2 Page 12 ...

Page 33: ...ServiceTraining Section 2 4 Page 1 2 4 STEERING SYSTEM ...

Page 35: ...ServiceTraining Section 2 4 Page 3 ...

Page 37: ...ServiceTraining Section 2 4 Page 5 ...

Page 39: ...ServiceTraining Section 2 4 Page 7 ...

Page 41: ...ServiceTraining Section 2 4 Page 9 ...

Page 45: ...ServiceTraining Section 2 4 Page 13 ...

Page 47: ...ServiceTraining Section 2 4 Page 15 ...

Page 53: ...ServiceTraining Section 2 5 Page 5 ...

Page 54: ...ServiceTraining Section 2 5 Page 6 ...

Page 69: ...ServiceTraining Section 2 6 Page 15 ...

Page 74: ...ServiceTraining Section 2 6 Page 20 2 6 2 3 CIRCUIT BREAKER CONTACTOR 1K6 Circuit diagram ...

Page 94: ...ServiceTraining Section 2 6 Page 40 ...

Page 111: ...ServiceTraining Section 2 6 Page 57 Connector 1X6 1 15 V 2 Output signal 3 ...

Page 126: ...ServiceTraining Section 2 6 Page 72 2 6 9 2 LOCATION OF CONNECTORS FROM SERIES 7 95 ...

Page 128: ...ServiceTraining Section 2 6 Page 74 ...

Page 145: ...Section 2 6 Page 91 ...

Page 146: ......

Page 147: ......

Page 149: ...Section 2 6 Page 93 ...

Page 150: ......

Page 153: ...ServiceTraining Section 2 7 Page 3 ...

Page 157: ...ServiceTraining Section 2 7 Page 7 ...

Page 158: ...ServiceTraining Section 2 7 Page 8 ...

Page 163: ...Section 2 9 Page 5 ...

Page 164: ......

Page 166: ...ServiceTraining Section 2 10 Page 2 ...

Page 167: ......