D-2

MAINTENANCE

PERIODIC MAINTENANCE

The product has been designed to function without problems for

many hours with minimal maintenance. In order to ensure this,

some simple regular maintenance and cleaning activities are

required which are described in this section. If you observe the

necessary caution and carry out the maintenance at regular

intervals, any problems that occur will be detected and corrected

before they lead to a total breakdown.

The indicated maintenance intervals can vary depending on the

specific working and ambient conditions. Therefore it is

recommended to thoroughly inspect the complete product once

every year other that the indicated periodic maintenance.

Follow OSHA protocols and your company's JHA safety

procedures when servicing this equipment. Keep personnel from

entering work area under unit and tether tools and anything else

that could fall to the floor.

The maintenance activities in Table D.1 indicated by [*] can be

carried out by the user; other activities are strictly reserved for

well trained and authorized service engineers.

The maintenance activities in Table D.1 indicated by [*] can be

carried out by the user; other activities are strictly reserved for

well trained and authorized service engineers.

* Frequency depends on welding or cutting process.

MAINTENANCE SCHEDULE

NOTE: * REQUIRES Lincoln Electric factory authorized service

technician.

AS NEEDED

• Replace filters (see filter replacement instructions).

• Inspect and test functionality of the filter media cleaning

system. *

• Program and verify system performance. *

• Follow governing local building codes for inspection

requirements following any significant event. Significant events

include but are not limited to seismic and other impacts to the

unit or structural mounts.

MONTHLY

• Check particulate collection drum and dispose of particulate if

necessary.

• Check and log filter pressure.

• Check fan speed.

• (Hanging mount): Visually inspect secondary support cables

are not taut. Taut cables can be an indication of primary support

failure.

EVERY 3 MONTHS

• Inspect and clean or replace pre-filters installed on the sides of

the unit.

EVERY 6 MONTHS

• Ensure that the Cubic Feet per Minute (CFM) is operating to the

engineered specifications based on the individual system *

• Clean inlet dampers as specified under the INLET DAMPERS

maintenance section.

YEARLY

• Inspect unit for proper operation and function, address any

issues found.

• Fan motor temperature is within normal ranges, a hand held IR

temp meter is a good tool for this. High motor temps indicate

bearing or winding issues and predict a failure. This can also

apply to the electrical power connections to the unit- elevated

temps on junction boxes and wire terminations are precursors to

problems.

• (Hang mount): Verify primary and secondary support brackets

and hardware remain properly in place with no signs of loosening.

• (Wall mount): Verify wall mount brackets, wall anchors and

other hardware remain in place with no signs of loosening.

• Inspect external unit components, including but not limited to

the door hinge, side intake housing and all hardware.

EVERY 5 YEARS

• Inspect condition of unit mounting. This includes but is not

limited to the building structure, brackets, hardware and any

other structural supports. Address any issues found.

MOTOR/FAN HOUSING

Observe safety precautions when working on the inside

of the fan box or control panel. Removing power and

observing LOTO (Lockout-Tagout) procedures as

required.

•

Check the integrity of the fan housing and tighten all

bolts and screws if necessary.

•

Clean housing with a non-aggressive detergent.

WARNING

PRISM® SUSPEND 4000

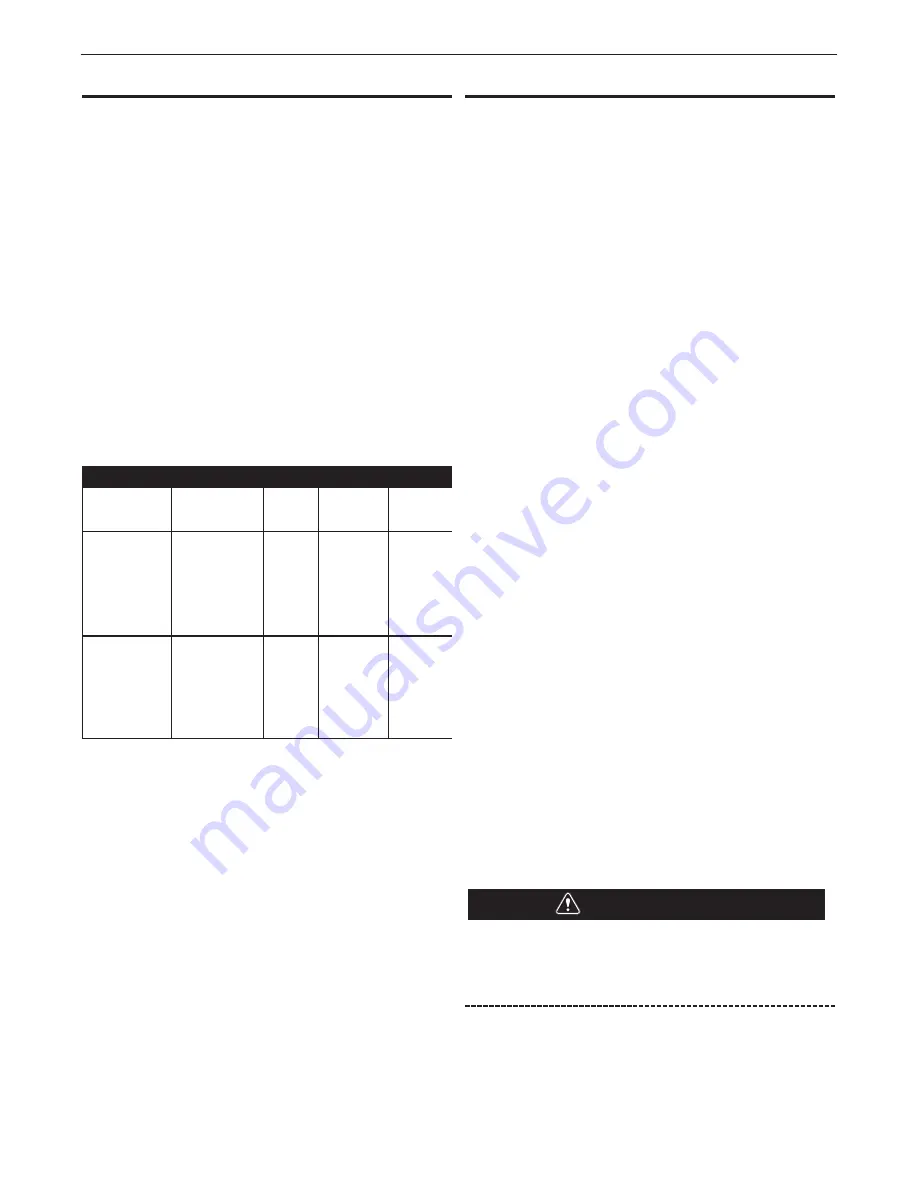

TABLE D.1 – PERIODIC MAINTENANCE

COMPONENT

ACTION

EVERY

MONTH

EVERY 3

MONTHS

EVERY 6

MONTHS

Control Panel

*Clean inside

using an

industrial

vacuum

cleaner.

X

Drum

*Check levels

of dust and dirt

particulate.

Empty if

necessary.

X

X

X