dependant)

Oil filter / Oil atomiser

Semi annually

/as required

(site

dependant)

Service check

/ operator

Check clean and change as

required.

Pilot turndown test

Annually (as

required)

Service Tech.

Required after service or repair

works – refer to manufacturer

instructions

Refractory hold in

Annually (as

required)

Service Tech.

See “pilot turndown test”

All routine checks should be carried out along with any local codes or site specific maintenance

requirements.

Please refer to heat exchanger manufacturer’s instructions for any further exchanger specific procedures for

fluid levels, heat and pressure tests.

All service works should be carried out by a fully trained technician to a safe and competent level. All

operators should be trained to a level that is suitable for the operation of the installed equipment.

Summary of Contents for LC Series

Page 3: ...Section 1 Legal statements and Disclaimers Burner assembly area ...

Page 7: ...Section 2 Burner Technical Data Gas flame firing at 12 300 000 btu hr ...

Page 9: ...Section 3 Component Information General assembled burner ...

Page 11: ...Section 4 Gas Manifold assembly Split gas head assembly ...

Page 16: ...Section 5 Oil Gun assembly Oil nozzle and lance assembly ...

Page 19: ...Section 6 Electrode settings Pilot injector and ignition setup ...

Page 22: ...Section 7 Burner Installation Limpsfield LC9 dual fuel burners on Hurst boilers ...

Page 24: ...Sample Typical fire tube installation ...

Page 25: ...Typical water tube installation ...

Page 29: ...Section 8 Typical Gas control Train 2 gas control train assembled ...

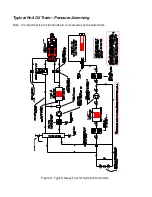

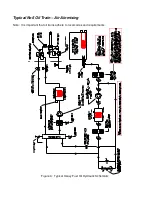

Page 32: ...Section 9 Typical Oil Train Assembled oil pump with filter ...

Page 36: ...Section 10 General start up procedure ...

Page 43: ...Section 11 Service Recommendations ...

Page 47: ...Section 12 General Burner Servicing Procedure ...

Page 52: ...Section 13 Fault Finding ...