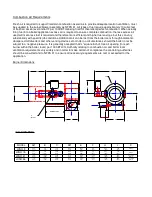

NFPA 85 – Typical fuels supply system and

safety control

P

G

P

G

P

S

L

P

O

C

P

O

C

P

S

H

P

G

G

a

s

s

u

p

p

ly

M

a

in

b

u

rn

e

r

N

T

H

T

T

T

M

T

I

A

S

R

C

K

L

A

I

Q

D

S

T

T

A

-

S

a

fe

ty

s

h

u

to

ff

v

a

lv

e

,

s

p

ri

n

g

c

lo

s

in

g

(

N

C

)

C

-

V

e

n

t

v

a

lv

e

,

sp

ri

n

g

o

p

e

n

in

g

(

N

O

)

D

-

G

a

s

m

o

d

u

la

tin

g

c

o

n

tr

o

l v

a

lv

e

(

A

u

to

fla

m

e

)

H

-

G

a

s

s

tr

a

in

e

r

I

-

P

ro

o

f

o

f

cl

o

su

re

s

w

itc

h

J

-

C

o

n

st

a

n

t

g

a

s

p

re

ss

u

re

r

e

g

u

la

to

r

va

lv

e

K

-

V

e

n

t

lin

e

m

a

n

u

a

l

sh

u

to

ff

v

a

lv

e

f

o

r

le

a

k

a

g

e

te

s

tin

g

(

lo

c

ke

d

o

e

s

e

a

le

d

o

p

e

n

)

L

-

L

e

a

k

a

g

e

t

e

s

t

c

o

n

n

e

c

tio

n

M

-

G

a

s

M

e

te

r

(o

p

tio

n

a

l)

N

-

D

ri

p

le

g

Q

-

H

ig

h

g

a

s

p

re

ss

u

re

s

w

it

ch

R

-

L

o

w

g

a

s

p

re

s

s

u

re

s

w

it

ch

S

-

P

re

ss

u

re

g

a

u

g

e

T

-

M

a

n

u

a

l s

h

u

to

ff

v

a

lv

e

X

-

L

o

w

f

ir

e

s

ta

rt

s

w

it

c

h

S

a

fe

ty

s

h

u

td

o

w

n

i

n

te

rl

o

c

k

s

(n

o

t

s

h

o

w

n

)

F

la

m

e

d

e

te

ct

o

r

(s

)

E

x

c

e

s

si

v

e

s

te

a

m

b

a

c

k

p

re

s

su

re

i

n

te

rl

o

c

k

(e

xc

e

ss

iv

e

w

a

te

r

te

m

p

e

ra

tu

re

a

n

d

p

re

s

su

re

in

te

rl

o

c

k

fo

r

h

o

t

w

a

te

r

b

o

ile

rs

)

A

u

xi

lia

ry

ll

o

w

w

a

te

r

c

u

to

ff

(

o

n

e

r

e

q

u

ir

e

d

)

C

o

m

b

u

s

tio

n

a

ir

s

u

p

p

ly

in

te

rl

o

ck

N

o

te

:

N

C

=

n

o

rm

a

lly

c

lo

se

d

,

d

e

-e

n

e

rg

iz

e

d

/

N

O

=

n

o

rm

a

lly

o

p

e

n

,

d

e

-e

n

e

rg

iz

e

d

.

S

S

T

o

p

ilo

t

a

s

s

e

m

b

ly

Summary of Contents for LC Series

Page 3: ...Section 1 Legal statements and Disclaimers Burner assembly area ...

Page 7: ...Section 2 Burner Technical Data Gas flame firing at 12 300 000 btu hr ...

Page 9: ...Section 3 Component Information General assembled burner ...

Page 11: ...Section 4 Gas Manifold assembly Split gas head assembly ...

Page 16: ...Section 5 Oil Gun assembly Oil nozzle and lance assembly ...

Page 19: ...Section 6 Electrode settings Pilot injector and ignition setup ...

Page 22: ...Section 7 Burner Installation Limpsfield LC9 dual fuel burners on Hurst boilers ...

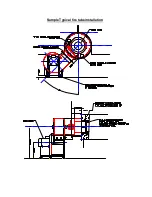

Page 24: ...Sample Typical fire tube installation ...

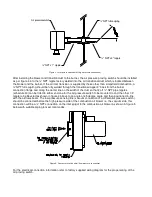

Page 25: ...Typical water tube installation ...

Page 29: ...Section 8 Typical Gas control Train 2 gas control train assembled ...

Page 32: ...Section 9 Typical Oil Train Assembled oil pump with filter ...

Page 36: ...Section 10 General start up procedure ...

Page 43: ...Section 11 Service Recommendations ...

Page 47: ...Section 12 General Burner Servicing Procedure ...

Page 52: ...Section 13 Fault Finding ...