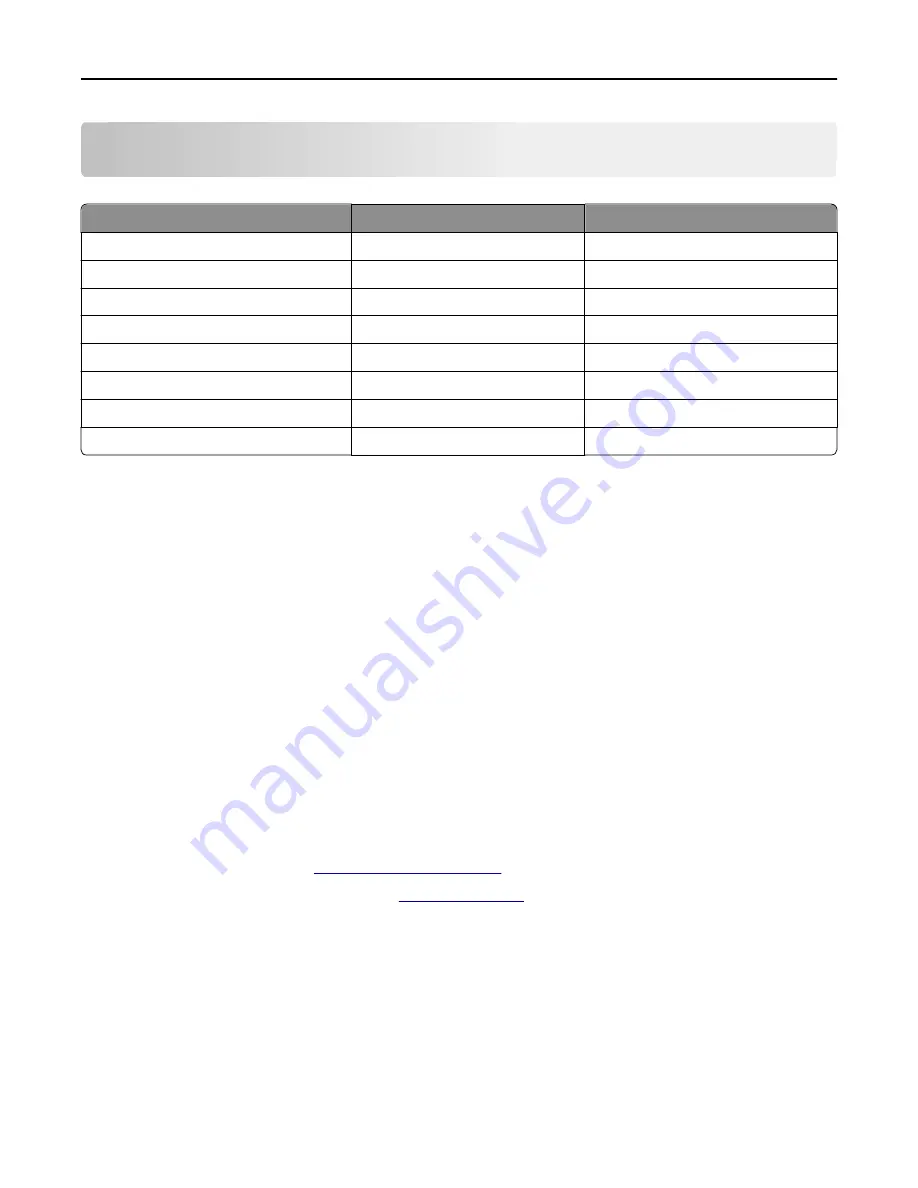

Notices

Product name

Machine type

Model number

Lexmark 2580+

2580

500

Lexmark 2580n+

2580

510

Lexmark 2581+

2581

500

Lexmark 2581n+

2581

510

Lexmark 2590+

2590

500

Lexmark 2590n+

2590

510

Lexmark 2591+

2591

500

Lexmark 2591n+

2591

510

Edition notice

January 2012

The following paragraph does not apply to any country where such provisions are inconsistent with local law:

LEXMARK INTERNATIONAL, INC., PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied warranties in certain

transactions; therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in later editions. Improvements or changes in the products or

the programs described may be made at any time.

References in this publication to products, programs, or services do not imply that the manufacturer intends to make

these available in all countries in which it operates. Any reference to a product, program, or service is not intended to

state or imply that only that product, program, or service may be used. Any functionally equivalent product, program,

or service that does not infringe any existing intellectual property right may be used instead. Evaluation and verification

of operation in conjunction with other products, programs, or services, except those expressly designated by the

manufacturer, are the user’s responsibility.

For Lexmark technical support, visit

http://support.lexmark.com

.

For information on supplies and downloads, visit

www.lexmark.com

.

If you don't have access to the Internet, you can contact Lexmark by mail:

Lexmark International, Inc.

Bldg 004-2/CSC

740 New Circle Road NW

Lexington, KY 40550

USA

© 2012 Lexmark International, Inc.

All rights reserved.

Notices

76