30

Digidrive SK Getting Started Guide

www.leroy-somer.com

Issue Number: d

0

:

keypad reference is zero

LASt

:keypad reference is last value selected before the drive was powered down

PrS1

:keypad reference is copied from preset speed 1

no

:

no action

rEAd

:program the drive with the contents of the SmartStick

Prog

:program the SmartStick with the current drive settings

boot

: SmartStick becomes read only. The contents of the SmartStick will be copied to

the drive every time the drive is powered up.

Parameter cloning is initiated by pressing the

MODE key on exit from parameter edit

mode after Pr

28

has been set to rEAd, Prog or boot.

no

:

defaults are not loaded

Eur

: 50Hz default parameters are loaded

USA

: 60Hz default parameters are loaded

Default parameters are set by pressing the

MODE key on exit from parameter edit

mode after Pr

29

has been set to Eur or USA.

When default parameters have been set, the display will return to Pr

01

and Pr

10

will be

reset to L1.

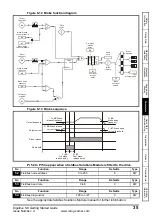

No

Function

Range

Defaults

Type

26

Not used

No

Function

Range

Defaults

Type

27

Power up keypad reference

0, LASt, PrS1

0

RW

No

Function

Range

Defaults

Type

28

Parameter cloning

no, rEAd, Prog, boot

no

RW

Before setting boot mode, the current drive settings must be stored in the SmartStick by

using Prog mode, otherwise the drive will trip on C.Acc at power-up. When boot mode is

enabled, it is impossible to return to rEAd or Prog mode. To disable this mode, please

get in touch with your usual LEROY-SOMER contact.

NOTE

M

If parameter cloning is enabled when no SmartStick is fitted to the drive, the drive will trip

on C.Acc.

The SmartStick can be used to copy parameters between drives of different ratings.

Certain drive dependant parameters will be stored on the SmartStick but will not be

copied to the cloned drive.

The drive will trip on C.rtg when being written to by a cloned parameter set of a different

drive rating.

The drive dependant parameters are: Pr

06

Motor rated current, Pr

08

Motor rated

voltage, Pr

09

Motor power factor and Pr

37

Maximum switching frequency.

For best motor performance, an autotune should be carried out after parameter cloning

has taken place.

Before the SmartStick /LogicStick is written to using Prog, the SmartStick/LogicStick will

need to be inserted into the drive at power up or a reset command performed when the

drive has been powered up, otherwise will trip on C.dAt when Prog command executed.

NOTE

NOTE

NOTE

No

Function

Range

Defaults

Type

29

Load defaults

no, Eur, USA

no

RW

M

The drive must be in a disabled, stopped or tripped condition to allow default parameters

to be set. If default parameters are set while the drive is running, the display will flash

FAIL once before changing back to no.

NOTE