System bus (CAN) with Servo PLC & Drive PLC

System blocks

6.6

CAN_Synchronization

6-23

L

PLC-Systembus EN 1.1

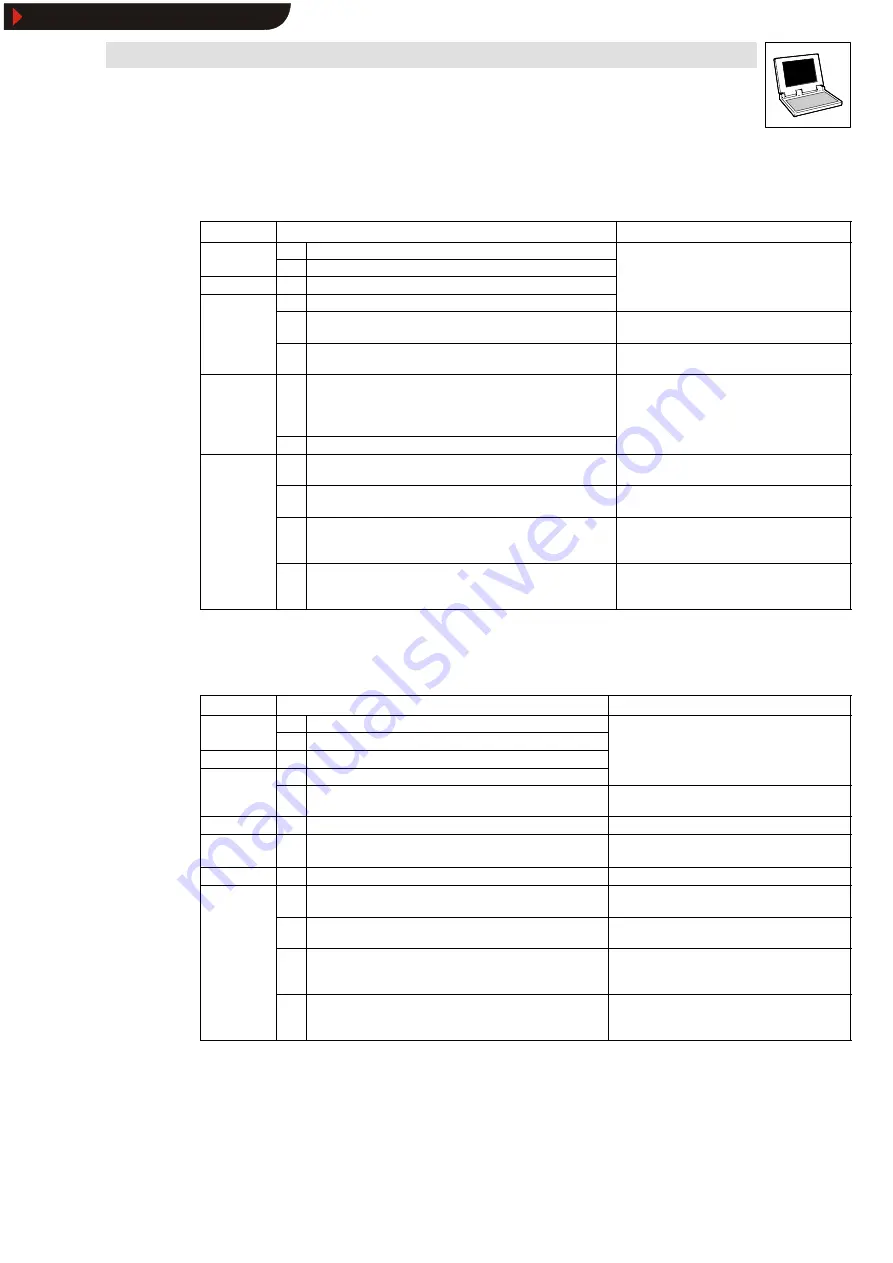

Configuration example: Synchronisation via system bus (CAN)

Proceed as follows when commissioning the system:

Location

Step

Info

All devices

1.

Commission drive controller/PLC and system bus.

2.

Inhibit drive controller/PLC.

DDS

3.

Integrate CAN_Synchronization SB into the control configuration.

Slaves

4.

Connect CAN_bSyncInsideWindow_b

with digital output.

5.

C1120 = 1

Synchronisation via system bus by Sync telegram

active.

6.

C0366 = 1 (Lenze default setting)

Sync response:

Slaves respond to Sync telegram.

Master

7.

Define telegram sequence (identifier)

1. Send new setpoint to all slaves,

2. Send Sync telegram

3. Receive response from all slaves

8.

Start communication, send Sync telegrams.

Slaves

9.

Read C0362 from master.

Poll cycle time of the Sync telegram from the ma-

ster.

10.

Set C1121 in conformance with C0362 from the master.

Adjust time between the Sync telegrams to be

received to the cycle time of the master.

11.

Set C1123.

Set the optimum size of the ”time window”.

•

If the Sync signal ”jitters” strongly, increase

”time window”.

12.

Enable drive controller/PLC via the

CAN_bSyncInsideWindow_b

signal on the digital output.

Synchronisation monitoring.

•

If

CAN_bSyncInsideWindow_b

= TRUE, enable

drive controller/PLC.

Configuration example: Synchronisation via terminal

Proceed as follows when commissioning the system:

Location

Step

Info

All devices

1.

Commission drive controller/PLC and system bus.

2.

Inhibit drive controller/PLC.

DDS

3.

Integrate CAN_Synchronization SB into the control configuration.

Slaves

4.

Connect CAN_bSyncInsideWindow_b

with digital output.

5.

Connect Sync signal of the master to the terminal.

9300 Servo PLC: Terminal X5/E5

Drive PLC: Terminal X3/I1

Slaves

6.

C1120 = 2

Synchronisation via terminal by Sync signal active.

Slaves

7.

C0366 = 1 (Lenze default setting)

Sync response:

Slaves respond to Sync telegram.

Master

8.

Start communication, send Sync signals.

Slaves

9.

Read C0362 from master.

Poll cycle time of the Sync telegram from the ma-

ster.

10.

Set C1121 in conformance with C0362 from the master.

Adjust time between the Sync telegrams to be re-

ceived to the cycle time of the master.

11.

Set C1123.

Set the optimum size of the ”time window”.

•

If the Sync signal ”jitters” strongly, increase

”time window”.

12.

Enable drive controller/PLC via the

CAN_bSyncInsideWindow_b

signal on the digital output.

Synchronisation monitoring.

•

If

CAN_bSyncInsideWindow_b

= TRUE, enable

drive controller/PLC.

Show/Hide Bookmarks