Page 12

505095M 1/3/06

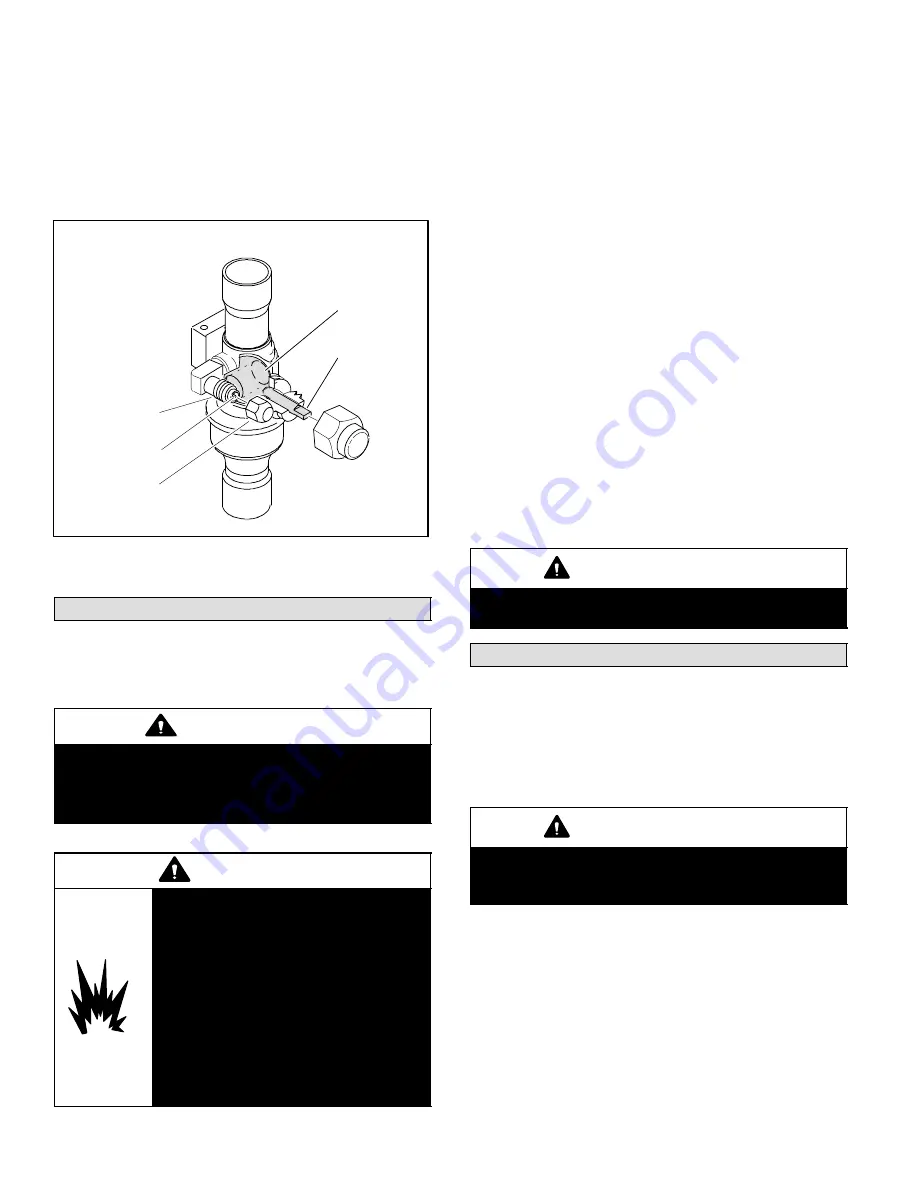

Vapor Line (Ball Type) Service Valve

Vapor line service valves function the same way as the oth-

er valves; the difference is in the construction. These

valves are not rebuildable. If a valve fails, replace it. The

ball valve (shown in figure 16) is equipped with a service

port with a factory−installed Schrader valve. A service port

cap protects the Schrader valve from contamination and

assures a leak−free seal.

Ball−Type Vapor Line Valve (Valve Closed)

Figure 16

BALL

(Shown

closed)

STEM

STEM

CAP

SERVICE

PORT

SCHRADER

VALVE

SERVICE

PORT CAP

To indoor coil

To outdoor coil

Use Adjustable Wrench

To close: rotate Stem

Counter-clockwise 90°.

To open: rotate Stem

Clockwise 90°.

Leak Testing

After the line set has been connected to the indoor and out-

door units, check the line set connections and indoor unit

for leaks.

WARNING

Refrigerant can be harmful if it is inhaled. Refriger-

ant must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

Danger of explosion: Can cause inju-

ry or death, or equipment damage.

Never use oxygen to pressurize a re-

frigeration or air conditioning system.

Oxygen will explode on contact with

oil and could cause personal injury.

When using a high pressure gas such

as dry nitrogen to pressurize a refrig-

eration or air conditioning system,

use a regulator that can control the

pressure down to 1 or 2 psig (6.9 to

13.8 kPa).

Leak Test with Electronic Leak Detector

1. Connect an R−410A manifold gauge set high pressure

hose to the vapor valve service port.

(Normally, the

high pressure hose is connected to the liquid line port;

however, connecting it to the vapor port better protects

the manifold gauge set from high pressure damage.)

2. With both manifold valves closed, connect the cylinder

of R−410A refrigerant to the center port of the manifold

gauge set. Open the valve on the R−410A cylinder (va-

por only).

3. Open the high pressure side of the manifold to allow

R−410A into the line set and indoor unit. Weigh in a

trace amount of R−410A.

[A trace amount is a maxi-

mum of 2 ounces (57 g) refrigerant or 3 pounds (31

kPa) pressure].

Close the valve on the R−410A cylin-

der and the valve on the high pressure side of the man-

ifold gauge set. Disconnect the R−410A cylinder.

4. Connect a cylinder of dry nitrogen with a pressure reg-

ulating valve to the center port of the manifold gauge

set.

5. Adjust dry nitrogen pressure to 150 psig (1034 kPa).

Open the valve on the high side of the manifold gauge

set in order to pressurize the line set and the indoor unit.

6. After a few minutes, open a refrigerant port to ensure

the refrigerant you added is adequate to be detected.

(Amounts of refrigerant will vary with line lengths.)

Check all joints for leaks. Purge dry nitrogen and

R−410A mixture. Correct any leaks and recheck.

IMPORTANT

Leak detector must be capable of sensing HFC re-

frigerant.

Evacuation

Evacuating the system of noncondensables is critical for

proper operation of the unit. Noncondensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Noncondensables and water vapor combine with

refrigerant to produce substances that corrode copper pip-

ing and compressor parts.

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

that reads from 50 microns to at least 23,000 microns.

1. Connect manifold gauge set to the service valve ports

as follows:

D

low pressure gauge to

vapor

line service valve

D

high pressure gauge to

liquid

line service valve

2. Connect micron gauge.

3. Connect the vacuum pump (with vacuum gauge) to

the center port of the manifold gauge set.

4. Open both manifold valves and start the vacuum

pump.

5. Evacuate the line set and indoor unit to an

absolute

pressure

of 23,000 microns (29.01 inches of mercu-