Page 14

XP14 SERIES

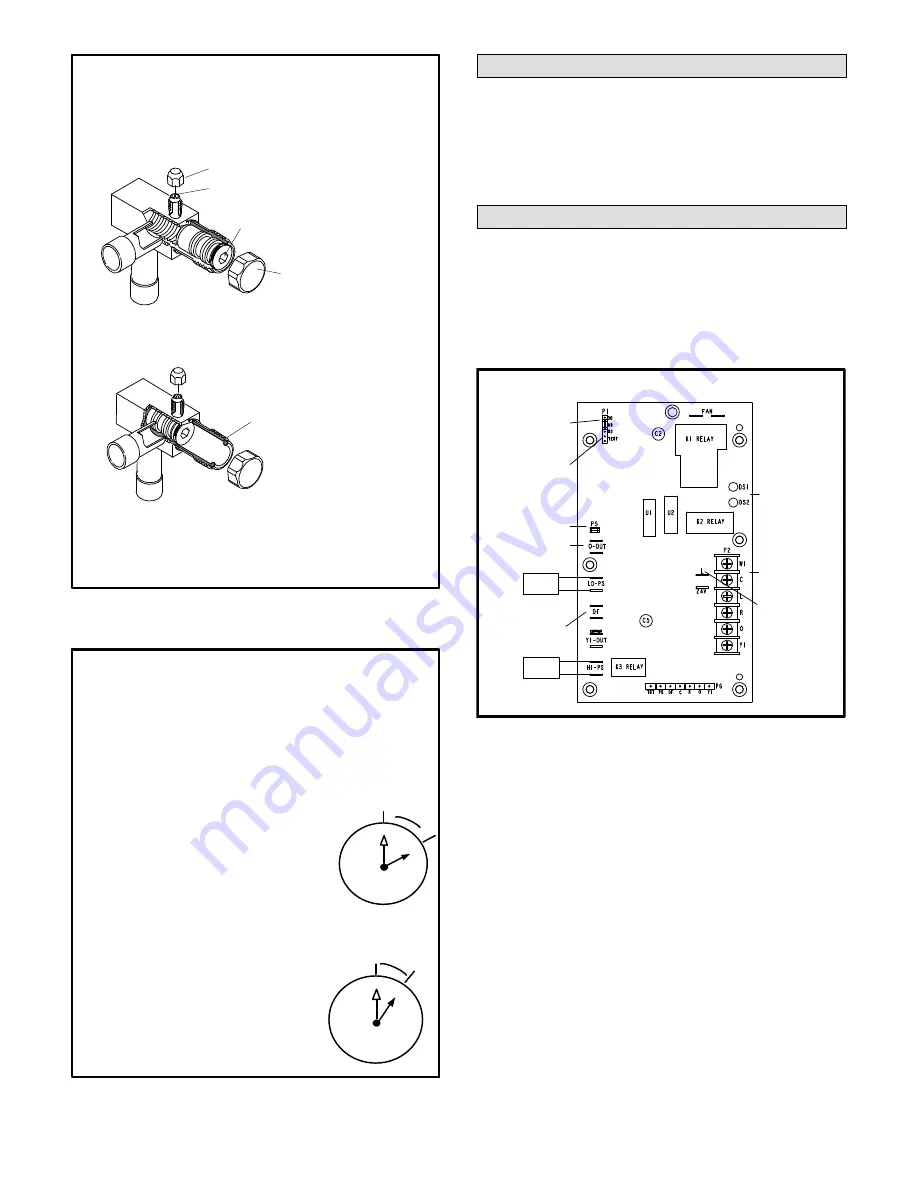

(VALVE STEM SHOWN CLOSED)

INSERT HEX WRENCH HERE

SERVICE PORT CORE

SERVICE PORT CAP

ANGLE-TYPE SERVICE VALVE

(FRONT-SEATED CLOSED)

STEM CAP

(VALVE STEM SHOWN OPEN)

INSERT HEX WRENCH HERE

ANGLE-TYPE SERVICE VALVE

(BACK-SEATED OPENED)

1 - Remove stem cap with an appropriately sized wrench.

2 - Use a service wrench with a hex-head extension (3/16” for liquid

line valve sizes and 5/16” for vapor line valve sizes) to back the

stem out counterclockwise as far as it will go.

When service valve is

CLOSED

, the service port is

open to the line set and indoor unit.

When service valve is

OPEN

, the service port is

open to line set, indoor and outdoor unit.

NOTE -

A label with specific torque requirements may be affixed to

the stem cap. If the label is present, use the specified torque.

OPERATING ANGLE-TYPE SERVICE VALVE

FIGURE 16

1

2

3

4

5

6

7

8

9

10

11 12

1/12 TURN

A service port cap protects the service port core from contamination

and serves as the primary leak seal.

1 - Remove service port cap with an appropriately sized wrench.

2 - Connect gauge set to service port.

3 - When testing is completed, replace service port cap and tighten

as follows:

S

With torque wrench, finger tighten and torque

cap per table 2.

S

Without torque wrench finger tighten and

use an appropriately sized wrench to turn

an additional 1/6 turn clockwise.

1

2

3

4

5

6

7

8

9

10

11 12

1/6 TURN

Reinstall Stem Cap

Stem cap protects the valve stem from damage and serves as the

primary seal. Replace the stem cap and tighten as follows:

S

With torque wrench, finger tighten and

then torque cap per table 2.

S

Without torque wrench, finger tight

en and use an appropriately sized

wrench to turn an additional 1/12

turn clockwise.

ACCESS SERVICE PORT

FIGURE 17

Checking Refrigerant Charge

The XP14 unit is factory-charged with enough HFC-410A

refrigerant to accommodate a 15-foot length of refrigerant

piping.

Charge should be checked and adjusted us

ing the tables provided on the charging procedure

sticker on the unit access panel.

Detailed information

is given in the XP14 Installation and Service Procedures

manual, which is available on DaveNet.

Defrost System

The defrost system includes a defrost thermostat (S6)

and a defrost control (CMC1).

DEFROST CONTROL (CMC1)

This defrost control includes the combined functions of a

time/temperature defrost control, defrost relay, time

delay, diagnostic LEDs and a terminal strip for field wiring

connections.

24V TERMINAL

STRIP

CONNECTIONS

DIAGNOSTIC

LEDS

HIGH PRESSURE

SWITCH

TEST

PINS

DEFROST TIMING

PINS (P1)

REVERSING

VALVE

DEFROST

THERMOSTAT (S6)

LOW PRESSURE

SWITCH

COMPRESSOR

DELAY PINS

S4

S87

SERVICE LIGHT

CONNECTIONS

DEFROST CONTROL (CMC1)

FIGURE 18

The defrost control provides automatic switching from

normal heating operation to defrost mode and back.

When the defrost thermostat is closed, the control accu

mulates compressor run time at 30-, 60- or 90- minute

field-adjustable intervals. When the selected compressor

run time interval is reached, the defrost relay is energized

and defrost begins.

Defrost Control Timing Pins (P1)

Each timing pin selection provides a different accumu

lated compressor run time period for one defrost cycle.

This time period must occur before a defrost cycle is ini

tiated. The defrost interval can be adjusted to 30 (T1),

60 (T2), or 90 (T3) minutes (see figure 18). The maxi

mum defrost period is 14 minutes and cannot be ad

justed.

NOTE -

Defrost control part number is listed near the

P1

timing pins.

S

Factory default is 90 minutes.

S

If the timing selector jumper is missing, the defrost

control defaults to a 90-minute defrost interval.