EM522-CAN Field bus Stepper Drive User Manual V1.0

Preface

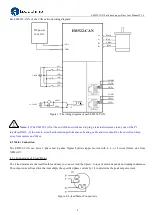

Thank you for you choose EM522-CAN stepper drive system of Leadshine Technology Co,.Ltd. This

manual gives required knowledge & precautions for using EM522-CAN.

Improper operation may cause an accident, please read this manual carefully before

operation.

●

Manual content may change due to product improvement, please forgive without prior notice.

●

Leadshine will not undertake any responsibility in case of user's unauthorized product changes,

product warranty will be invalid.

Please pay attention to the following reminders:

CAUTION

●

Only the technical personnel to install,debug or maintain the product.

●

To ensure correct wiring before power-on test.

●

Incorrect voltage or power polar can cause damage to drive or other accidents