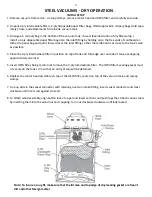

PneUmAtic motor VerSion

initiAl SetUP

1. Secure a compressed air source capable of supplying a minimum 80 - 100 psi and 70 cfm flow rate. A minimum

hose I.D. of a 1/2” is required to connect to a 1/2” Industrial Interchange style male plug.

2. The air motor has no moving parts and requires no service if the air source is clean air, free of oil and water. An

“on-oFF” valve is provided to regulate flow to the air motor.

Warning:

operating this air motor above 100 psi may cause implosion of the metal can.

Do not tamper with the relief valve supplied internally on the air motor.

Filter maintenance

caution:

Always unplug vacuum from power source before changing filters.

2-Ply Disposable Paper Filter Bag

When the 2-ply disposable paper bag is full, it must be replaced. Excessive overfilling of this bag makes if difficult

to remove from the vacuum tank and can result in breakage and/or spills.

2-Ply intermediate Filter

The 2-ply intermediate filter should be replaced with every fifth (5) change of the paper bag, or whenever there is

damage or visible collection of debris on the outside of the filter.

HePa Filter

Replace the HEPA filter when loss of suction continues to occur after you have checked for an obstruction in the

hose or wand, installed a new 2-ply-disposable paper filter bag, and installed 2-ply intermediate filter.

caution:

Hazardous materials must be disposed of properly. nEVER throw contaminated debris in your standard

trash receptacle. Place debris in a 6 mil poly bag or container marked with HAZARDoUS MATERIALS warning and

dispose of in accordance with your local hazardous waste regulations.

eQUiPment mAintenAnce

Contact distributor or manufacturer to receive written authorization for return of vacuum. Transportation

charges to the service location must be paid by the purchaser.

Any w

arranty is void if electrical components

are ser

-

viced by non-factory service personnel. The use of non-certified parts can result in possible safety

hazards and void UL certifications.

6