Absolute HEPA filtered vacuums are designed for industrial plants, clean rooms, nuclear plants or wherev

-

er dangerous air or dust pollutants must be removed. Triple filtration provides 99.97% efficiency in retention of

particles down to 0.3 microns in size. Absolute filters are a necessity when an extremely high level of cleanliness

is required for the removal of asbestos, lead, and other toxic dusts. Each absolute filter at its final assembly, is

tested and labeled by the manufacturer to the latest industrial standards and specifically to the UL-586 standard.

Precision testing is performed with thermally generated D.o.P. (Doctyl Phthalate) aerosol according to Mil-Stan

-

dard 282. The test machinery is specially designed to assure the guaranteed efficiency of 99.97% on a particle

size of 0.3 microns. Each absolute filter is individually tested and certified by the manufacturer, with a promi

-

nently displayed label showing results of the actual D.o.P. test.

3-Stage HePa Filtration SyStem

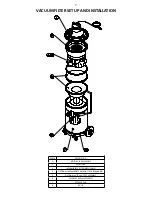

StAGe 1

Totally enclosed double-ply paper filter bag with special fold-over self-adhesive seal patch. Throwaway bags are

stenciled with caution instructions for disposal purposes. Paper bags produce filtration efficiency down to 5 mi

-

crons.

StAGe 2

Intermediate filter made of double-ply nonwoven media. The filter has a sewn-in elastic top to fit around the

HEPA filter. (Elastic is placed below rim of HEPA filter). When used with Stage 1 paper bag, filtration efficiency is

down to 2 microns.

StAGe 3

Certified absolute filter is constructed of an aluminum outer casing with filter media of high strength micro-fi

-

bered glass paper separated by corrugated aluminum sheeting that is entrapped in steel screening for protec

-

tion against damage to media. The HEPA filter is designed to filter particles down to 0.3 microns. Absolute filter

meets AnSI Standard Z9.2 and UL-586 Standard. For models AV-2, AV-2BP, AV-2P, and AV-2PBP, the certified abso

-

lute filter has a molded plastic housing. It meets the same specifications, and meets AnZI Standard Z9.2.

oVerVieW

3