36

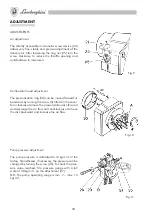

GAS PRESSURE SWITCH (4) (Fig. 5)

The gas pressure switch must be calibrated to such a pressure that in the event of a drop in the gas

feed pressure, the pressure switch intervenes stopping the burner before the flame range goes to

below the minimum of the burner.

The gas pressure switch intervention stops the burner only for the period of low pressure; as soon as

the pressure returns to normal, the burner will be restarted.

To adjust the gas pressure switch intervention pressure turn the ring nut.

Fig-3

Fig-4

Fig-5

To adjust the initial flow rate, remove the protective cap,

turn it upside down and position it on the screw.

The flow rate is decreased by tightening and increased

by loosening.

To adjust the total flow rate, loosen the screw (A) by two

or three turns, then turn the knob (B).

Turn the knob clockwise to decrease the flow rate and

anticlockwise to increase it

INITIAL AND TOTAL FLOW ADJUSTMENT OF THE MAIN ELECTROVALVE

AIR PRESSURE SWITCH (40) (Fig. 4)

The air pressure switch is calibrated at the factory. When there is insufficient air pressure during

operation, the pressure switch intervenes and locks the burner. Before reattempting to start it, check

that the fan or the pressure switch is working properly.