43

The boilers leave the factory calibrated and predisposed to operate with NATURAL GAS and LIQUID GAS.

These calibrations are effected without the connection of the compensating joint (Pos. A).

For the calibrations to put into effect, see the table related below:

BURNER PRESSURE CURVES - OUTPUT

GAS - NOZZLE CALIBRATION

Pressure on nozzles mbars

Delivery

Burner

nozzles

min.

max.

m

3

/h

Ø mm.

Gas type

NATURAL GAS

(G20-20mbars)

LIQUID GAS B

(G30-28/30mbars)

LIQUID GAS P

(G31-37mbars)

2

5

6,2

11

25

32

3,06

0,89

1,17

1,25

0,77

0,77

L.C.V.

kcal/h

8.550

29.330

22.360

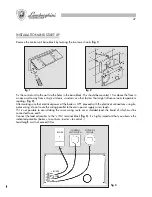

A

Compensating joint

B

Connecting pipe

To effect the gas valve calibration,

proceed as follows:

a)

take the pipei

B

off the joint

A

;

b)

effect calibration;

c)

connect the pipe

B

again to the joint

A

.

94

La caldera prevé la posibilidad de adoptar la potencia térmica en calefacción a la demanda térmica de los

locales que haya que calentar (sin que varíe la potencia disponible para la producción de agua caliente

sanitaria).

Todas las calderas salen de la fábrica ajustadas al 70% de su potencia máxima. Para adaptar la caldera a la

potencia solicitada por la instalación hay que efectuar las operaciones siguientes:

●

introducir un manómetro en la toma de presión (

G

)

●

alimentar eléctricamente la válvula gas poniendo el selector en la posición INVIERNO

●

intervenir en el potenciómetro de calefacción (

1

) situado en la tarjeta modulación hasta alcanzar la

presión de gas requerida por la potencialidad de la instalación de calefacción (ver curvas de presión).

Si fuera necesario intervenir en la regulación de la potencialidad mínima y máxima (pre calibradas en

fábrica),para la producción de agua sanitaria, efectúen las siguientes operaciones:

●

desunir los contactos de alimentación de la bobina (

E

)

●

alimentar eléctricamente la válvula de gas con la caldera encendida en la posición VERANO y trasegar

agua caliente sanitaria al máximo del caudal (13,1 l./minuto)

●

apretar a fondo, sin la ayuda de herramientas, el tornillo de regulación (

D

)

●

aflojar la contratuerca (

B

)

●

maniobrar con una llave en el tornillo (

A

) de la bobina hasta obtener los valores de presión de gas

máximos citados en la pag. 74

●

bloquear la contratuerca (

B

)

●

destornillar el tornillo de regulación (

D

) hasta alcanzar los valores de presión de gas mínimos citados en la pag. 74

●

volver a conectar la bobina (

E

)

Tales operaciones permitirá ahora a la caldera, satisfacer las exigencias de los utilizadores.

NOTA: Para realizar este ajuste es necesario utilizar un manómetro de columna de agua conectándolo a la

toma de presión (G).

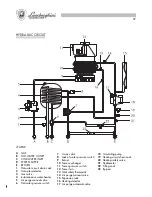

REGULACIONES

DESCRIPCIÓN

A

Tornillo reg. potencia max.

B

Contratuerca bloqueo

regulación

C

Muelle

D

Tornillo regulación

potencia mínima

E

Bobina

F

Resorte

G

Toma de presión

H

Centralita

I

Diafragma gas

(eventual)

L

Toma de compensación

Tarjeta modulación

Summary of Contents for thin 24 MCS W TOP U/IT

Page 3: ......

Page 5: ......

Page 7: ......

Page 9: ......

Page 11: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 23: ......

Page 25: ......

Page 27: ......

Page 29: ......

Page 31: ......

Page 33: ......

Page 35: ......

Page 37: ......

Page 39: ......

Page 41: ......

Page 43: ......

Page 45: ......

Page 47: ......