50

●

COPYING HOURLY PROGRAMMING

To speed up programming, you can “paste” the settings for a specific day onto another day.

Press

V

to select the day from which you wish to copy the settings.

Press the

Copy

key within 5 seconds to copy and then press the

+

and

–

keys to select the page onto which

you intend to “paste” them (the “destination” day is indicated by a flashing

indicator).

Press

P

to paste and memorise the settings or

V

to cancel.

●

TEMPORARY TEMPERATURE VARIATION

It is possible to vary set room temperature during automatic temperature control mode by acting on the

+

and

–

keys. Variations will be shown on the display.

When this function is used the symbol indicating the present level goes out and the indicator light corresponding

to the relevant time slot starts flashing.

The new temperature will remain operative until the next value change, after which the programme will revert

to normal settings.

NOTE:

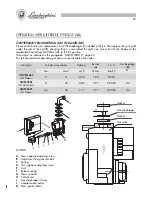

Immediately after setting the date and the day (section 2) a factory-set default programme is activated.

This programme is given in the table below.

Standard Programme

from Monday to Friday

Saturday and Sunday

Low temp.

23:00+06:00

23:00+08:00

Comfort temp.

06:00+09:00

08:00+23:00

Low temp.

09:00+17:00

Comfort temp.

17:00+23:00

“MANUAL” TEMPERATURE CONTROL MODE

Pressing the

key enables manual operation of temperature control.

When manual mode is selected the

symbol appears on the display.

This mode excludes the daily/weekly timer and adjusts rooms temperature according to a standardised tem-

perature setting (modified by pressing

+

or

-

).

87

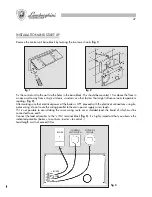

CONEXIÓN HIDRÁULICA

Una vez colocados los ganchos de sujeción metan la plantilla de montaje y apóyenla contra la pared; después

de haber fijado las uniones terminales montadas previamente en la plantilla, procedan a poner todas las

tuberías: ida instalación, retorno instalación, agua fría, agua caliente, y eventualmente también las de gas y

alimentación de la línea eléctrica con termostato ambiente.

Una vez puestas las tuberías se pueden desenroscar las uniones terminales y meter tapones normales cerrados

para pasar a la prueba hidráulica de la instalación. La plantilla la podemos dejar o quitar, ya que después de

las operaciones de acabado de la pared (enlucido o azulejos), quedará completamente cubierta; se verán

sólo fuera de la pared terminada los dos ganchos de sujeción, y quedará una apertura que corresponderá

con los empalmes. A continuación pongan la caldera sobre los dos ganchos de sujeción mediante los agujeros

correspondientes en la parte posterior del armazón, apóyenla completamente contra la pared y fijen las

tuercas de inmovilización en los ganchos.

Por último efectúen la conexión hidráulica mediante los tubos que se dan con el equipamiento base, cortándolos

a medida, según la distancia que haya entre las juntas de la caldera y las de la plantilla colocadas en la

pared.

DESCRIPCIÓN

C

Agua caliente Ø 1/2"

G

Gas Ø 3/4” ( Véase grifo en

dotación )

F

Agua alimentación caldera Ø

1/2" (Fría)

AE

Alimentación eléctrica

M

Ida instalación Ø 3/4"

R

Retorno instalación Ø 3/4"

GS

Ganchos de sujeción Ø 10 mm

NOTA:

Preparar piezas

hidráulicas de unión

hembra

Summary of Contents for thin 24 MCS W TOP U/IT

Page 3: ......

Page 5: ......

Page 7: ......

Page 9: ......

Page 11: ......

Page 13: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 23: ......

Page 25: ......

Page 27: ......

Page 29: ......

Page 31: ......

Page 33: ......

Page 35: ......

Page 37: ......

Page 39: ......

Page 41: ......

Page 43: ......

Page 45: ......

Page 47: ......