General Maintenance

25

Packer

The M

INIMAX

™ packer (see Figure 3-2) is submitted to intensive use during a work day (1000 to

3000 cycles). Therefore, some of its components have to be regularly looked at: the wear pads, which

are located at both sides of the packer and inserted in the body side rails, the follower panels, and the

rollers, which are also inserted in the body side rails (see Figure 3-3).

Labrie Enviroquip Group recommends that

operators

perform a daily visual inspection of the packer

and its components.

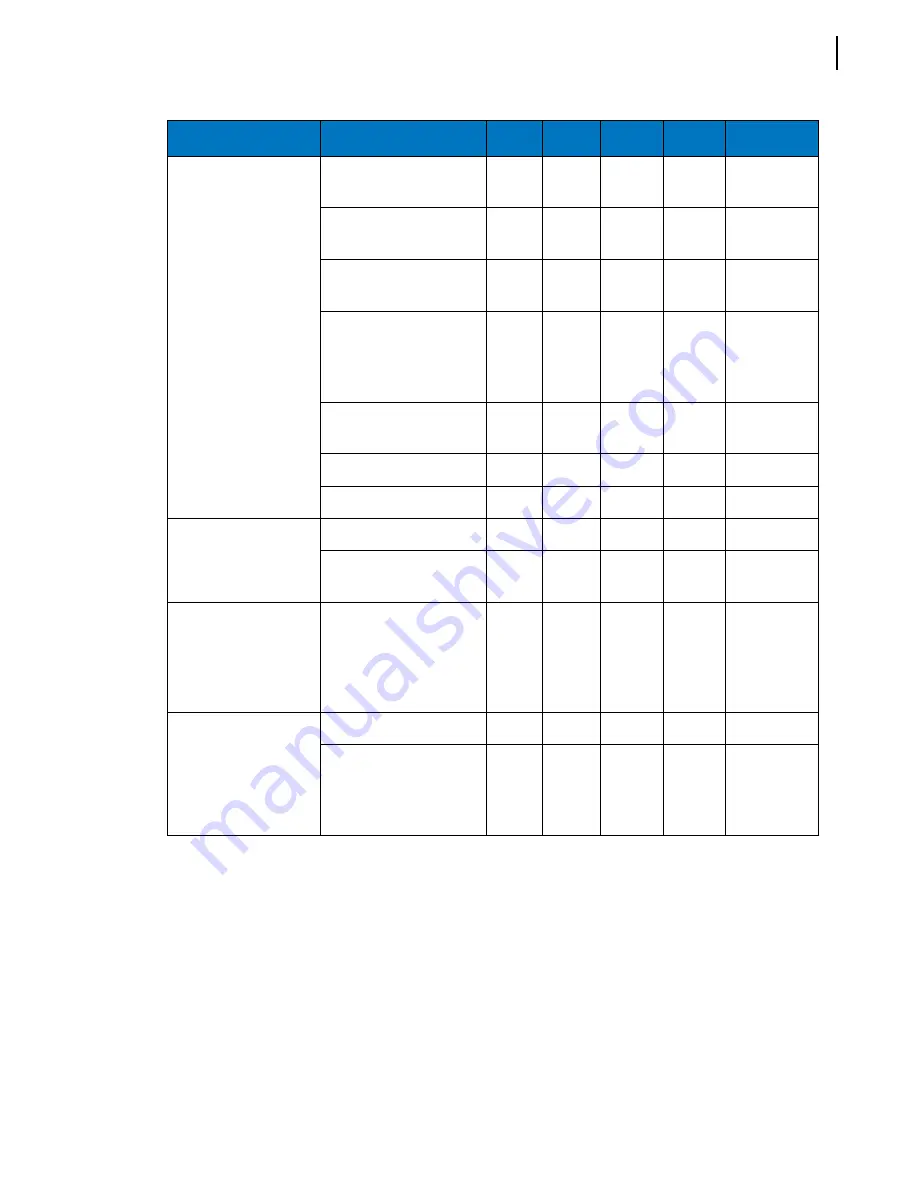

Hydraulic system

Check oil level in tank,

and refill if necessary

X

Check if the ball valve

on suction line is open

X

Check on ground for

overnight leaks

X

Check cylinders, pump,

control valve and

system for leaks. Repair

or replace if required

X

Replace hydraulic filter

a

Twice a

year

Clean strainer and refill

X

Check pressure

X

Hopper area

Clean traps on each side

X

Clean dirt around the

packer

X

Visual inspection

Rollers, hydraulic

cylinder and cylinder

pins, hoses, pipes and

connections, wear of

floor and hopper sides.

X

Body and chassis

Check for corrosion

X

Keep the contact

surfaces clean between

the body and the

chassis.

X

a.

Also replace the return filter after the first 50

hours of use.

Component/System

Verification

Daily

Weekly Monthly Yearly

Page

Summary of Contents for MINIMAX

Page 1: ...MINIMAX TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...MINIMAX MAINTENANCE MANUAL...

Page 8: ...vi Table of Contents Adjusting Arm Speed 164...

Page 30: ...22 Safety Figure 2 17 Drain valve on air tank...

Page 72: ...64 Lubrication Figure 4 10 Lubrication chart Helping Hand arm...

Page 80: ...72 Lubrication...

Page 90: ...82 Hydraulic System Figure 5 8 Oil temp level gauge Figure 5 9 Steel hydraulic tank...

Page 102: ...94 Hydraulic System Figure 5 21 Strainer assembly Strainer...

Page 106: ...98 Hydraulic System Figure 5 25 Detecting cylinder internal leaks 1 2 3 4 5 A A A...

Page 108: ...100 Hydraulic System...

Page 113: ...Electrical System 105 Electrical Schematics Cab Adaptation...

Page 114: ...106 Electrical System Cab Console Controls...

Page 115: ...Electrical System 107 Cab Controller...

Page 116: ...108 Electrical System Chassis...

Page 117: ...Electrical System 109 Body Module rear side...

Page 118: ...110 Electrical System Body Module front side...

Page 119: ...Electrical System 111 Tailgate Lighting...

Page 120: ...112 Electrical System Panic Bars Crusher Panel Tipper Interlocks...

Page 121: ...Electrical System 113 Cameras Switchpack Details Interlocks AUTO 10 SEC INHIBIT AUTO N AUTO ON...

Page 122: ...114 Electrical System...

Page 127: ...Troubleshooting 119 Figure 8 4 Ball end hex wrench metric and SAE...

Page 134: ...126 Troubleshooting Figure 8 6 Tailgate locking mechanism...

Page 156: ...148 Multiplexing...

Page 162: ...154 Multiplexing...

Page 164: ...156 Lifting Arm Figure 10 1 Mounting bolts Figure 10 2 Helping Hand gripper Figure 10 3 Hoses...