Troubleshooting

125

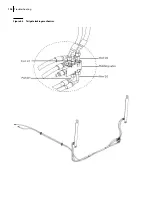

Figure 8-5 Plug to loosen

I

MPORTANT

:

Do not activate any hydraulic function during system bleeding.

6.

When the noise stops, tighten the pipe/hose fitting.

7.

Cycle the packer to ensure there are no leaks and the pump is running smoothly.

8.

Disconnect the gauge.

Tailgate Locking Mechanism

N

OTE

:

Refer to the main hydraulic schematic.

The tailgate locking mechanism is equipped with hydraulic safety devices that prevent accidental

unlocking of the tailgate during operation. One of these devices is the velocity fuse (see Figure 8-7)

with the

power bleed

feature; the other is the holding valve (see Figure 8-6).

The spool inside the tailgate section of the valve is designed in such a way as to allow pressure to pass

through it every time pressure is building up in the hydraulic system (that is when the packer is

working). The pressure “burst” goes to the holding valve into port D1 and then out to the cylinder

through port U1 (see Figure 8-6). This will keep the tailgate cylinders pressurized and the tailgate

closed when packing refuse.

The velocity fuse, located on the right-hand side of the valve, will make sure to drain any slow moving

oil coming from the piston side of the tailgate cylinders. Since the rod side is being pressurized with

the “power bleed” system, the other side has to drain to avoid any pressure build-up. The velocity fuse

makes the piston side open to tank when the oil is moving under 3

gallons per minute, and will shut

close when a flow signal is sent.

Summary of Contents for MINIMAX

Page 1: ...MINIMAX TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...MINIMAX MAINTENANCE MANUAL...

Page 8: ...vi Table of Contents Adjusting Arm Speed 164...

Page 30: ...22 Safety Figure 2 17 Drain valve on air tank...

Page 72: ...64 Lubrication Figure 4 10 Lubrication chart Helping Hand arm...

Page 80: ...72 Lubrication...

Page 90: ...82 Hydraulic System Figure 5 8 Oil temp level gauge Figure 5 9 Steel hydraulic tank...

Page 102: ...94 Hydraulic System Figure 5 21 Strainer assembly Strainer...

Page 106: ...98 Hydraulic System Figure 5 25 Detecting cylinder internal leaks 1 2 3 4 5 A A A...

Page 108: ...100 Hydraulic System...

Page 113: ...Electrical System 105 Electrical Schematics Cab Adaptation...

Page 114: ...106 Electrical System Cab Console Controls...

Page 115: ...Electrical System 107 Cab Controller...

Page 116: ...108 Electrical System Chassis...

Page 117: ...Electrical System 109 Body Module rear side...

Page 118: ...110 Electrical System Body Module front side...

Page 119: ...Electrical System 111 Tailgate Lighting...

Page 120: ...112 Electrical System Panic Bars Crusher Panel Tipper Interlocks...

Page 121: ...Electrical System 113 Cameras Switchpack Details Interlocks AUTO 10 SEC INHIBIT AUTO N AUTO ON...

Page 122: ...114 Electrical System...

Page 127: ...Troubleshooting 119 Figure 8 4 Ball end hex wrench metric and SAE...

Page 134: ...126 Troubleshooting Figure 8 6 Tailgate locking mechanism...

Page 156: ...148 Multiplexing...

Page 162: ...154 Multiplexing...

Page 164: ...156 Lifting Arm Figure 10 1 Mounting bolts Figure 10 2 Helping Hand gripper Figure 10 3 Hoses...