LAARS Heating Systems

Page 56

present the keyboard screen. Use the “BS”

(BackSpace) key to erase the existing name.

Enter the new name, then press OK.

6. Now you can rename the other control on

Boiler 1 – the Secondary control. Press the

Home button in the top left-hand corner to go

back to the ‘home’ screen which shows the

different controls (Fig. 52).

7. This time, press the icon for the Secondary

control. Repeat steps 1 through 5. Change the

name to “Boiler 1 Secondary.”

8. Go to the Touch Screen for the next boiler

in the system. Repeat steps 1 through 7 for

each of the controllers on that boiler. Be sure

the names you enter are correct – each name

should indicate the Boiler number and whether

the control will operate as the Primary or

Secondary.

9. Repeat the process for any other boilers in the

system.

Job C – Make One Control the Lead/Lag

Master

(This is an individual function – do this once for the control that

will act as the Lead/Lag Master. Use the Touch Screen on Boiler

1.)

The Lead/Lag control system uses one controller

as the Lead/Lag Master. This controller supervises

the operation of the other controllers, and they all

operate together as part of the Lead/Lag system.

There is only one Lead/Lag Master in the system.

Usually, the controller used for this is the Primary

controller on Boiler 1. (Other controls in the

system can be set as the Lead/Lag Master, but we

do not recommend this because it may complicate

troubleshooting and technical support questions.)

The controller used as the Lead/Lag Master will also

do a second job, operating as Slave 1 in the Lead/

Lag system. A single controller performs both of

these functions. When it arrives from the factory,

the controller used for this should already be set up

as a slave – we will check that in a moment. For

now, we will just concentrate on enabling the Master

function.

1.

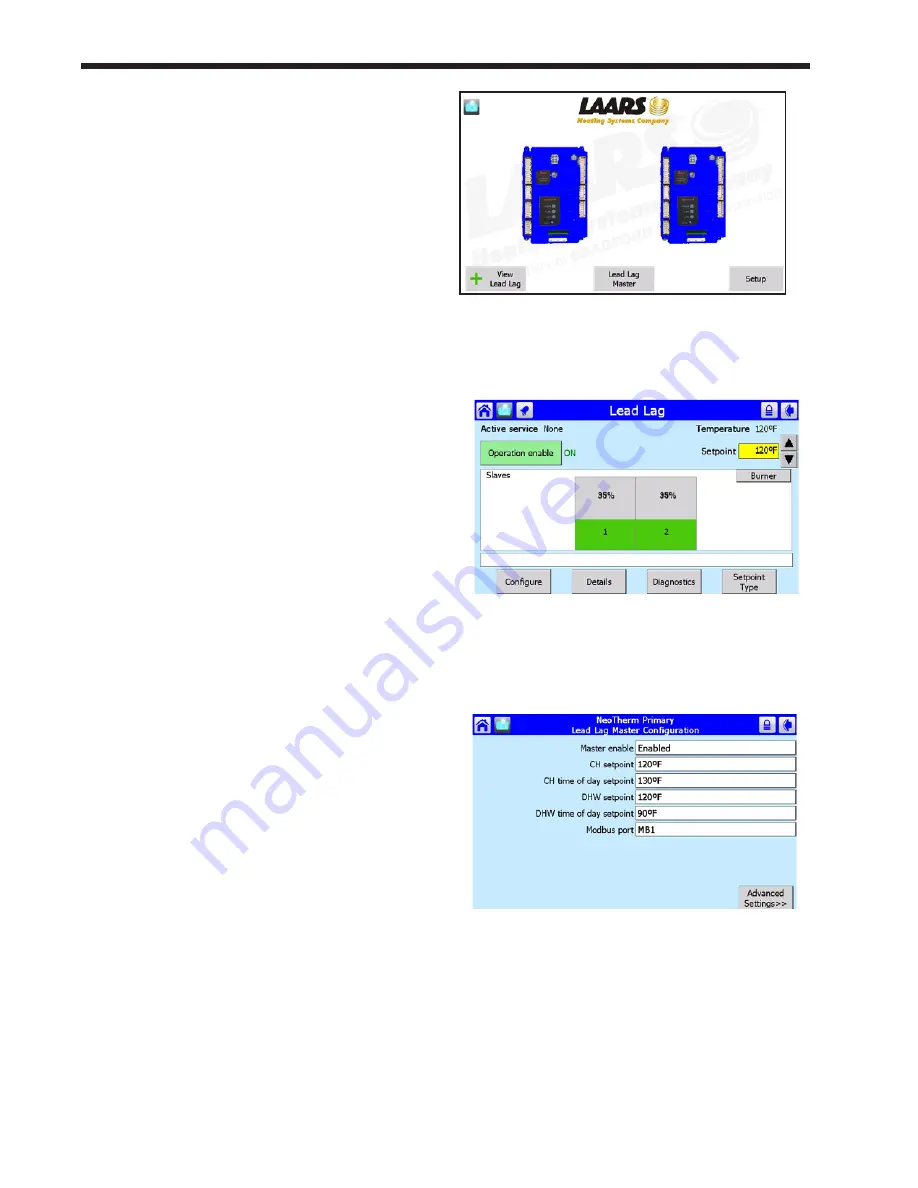

Start at the ‘home’ screen. See Fig. 56.

Fig. 56 – ‘home’ screen

2. Press the button for Lead Lag Master. Fig. 57

shows the screen that follows.

Fig. 57 – Lead/Lag Master Screen

3. Press the Configure button. The display will

present the Lead/Lag Master Configuration

Screen (Fig. 58).

Fig. 58 – Lead/Lag Master Configuration

4. This screen shows the most important settings

for the Lead/Lag system. The settings can be

changed from this screen. Some of them will

require passwords.

We will enter all of the Lead/Lag control

values in a moment. For now, just press on the

line for Master Enable. Change the setting to

Enable.

Summary of Contents for NTH1000

Page 4: ...LAARS Heating Systems ...

Page 11: ...NeoTherm LC Boilers and Water Heaters Page 7 Fig 6 Dimensions NT 1700 ...

Page 37: ...NeoTherm LC Boilers and Water Heaters Page 33 Fig 21 Ladder Diagram ...

Page 38: ...LAARS Heating Systems Page 34 Fig 22 Wiring Diagram ...

Page 39: ...NeoTherm LC Boilers and Water Heaters Page 35 ...

Page 51: ...NeoTherm LC Boilers and Water Heaters Page 47 Fig 51 Connection Terminals ...

Page 128: ...LAARS Heating Systems Page 124 Fig 140 Machine Frame NT1000 13 3 Parts Illustrations ...

Page 130: ...LAARS Heating Systems Page 126 Fig 143 Machine Frame NT1700 ...

Page 132: ...LAARS Heating Systems Page 128 Fig 145 Burners and Combustion Chamber NT1000 ...

Page 133: ...NeoTherm LC Boilers and Water Heaters Page 129 Fig 146 Burners and Combustion Chamber NT1700 ...

Page 135: ...NeoTherm LC Boilers and Water Heaters Page 131 Fig 149 Burner Detail NT1700 ...

Page 136: ...LAARS Heating Systems Page 132 Fig 150 Electronic Components Fig 151 Condensate Trap NT1000 ...

Page 138: ...LAARS Heating Systems Page 134 This page intentionally left blank ...

Page 139: ...NeoTherm LC Boilers and Water Heaters Page 135 This page intentionally left blank ...