Page 15

NOTICE

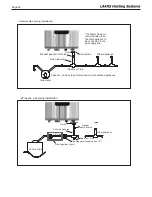

The instructions for the installation of the venting

system shall specify that the horizontal portions of

the venting system shall be supported to prevent

sagging; the methods of and intervals for support

shall be specified. These instructions shall also

specify that the venting system:

Category IV water heaters must be installed so

that horizontal sections have a slope of at least ¼

inch per foot (21mm/m) to the appliance to prevent

accumulation of condensate; and

For Category IV water heaters, where necessary,

have means provided for drainage of condensate.

AVIS

Les instructions d'installation du système

d'évacuation doivent préciser que les sections

horizontales doivent être supportées pour prévenir

le fléchissement. Les méthodes et les intervalles

de support doivent être spécifiés. Les instructions

doivent aussi indiquer les renseignements

suivants:

les chaudières de catégories IV doivent présenter

des tronçons horizontaux dont la pente montante

est d'au moins ¼ po par pied (21 mm/m) entre la

chaudière et l'évent; les chaudières de catégories

IV doivent être installées de façon à empêcher

l'accumulation de condensat;

et si nécessaire, les chaudières de catégories

II et IV doivent être pourvues de dispositifs

d'évacuation du condensat.

The LT Series comes from the factory set to use

either Natural gas or Liquid Propane. Confirm the

installation gas type matches the gas type on the

rating plate.

Adequate drainage

• The appliance should be installed not to damage

the adjacent area. If such locations cannot be

avoided, it is recommended that a suitable drain

pan, adequately drained, be installed under the

appliance. The pan must not block combustion

air flow.

Connecting the Water Supply

• To conserve water and energy, insulate all water

piping—especially the hot and recirculation water

lines. Never cover the drain or pressure relief

valve.

Having a backflow preventer in the cold water

supply line means that it prevent from thermal

expansion backflow. Contact the water supplier

or local plumbing inspector for information about

how to control this situation. If overheating

occurs or the gas supply fails to shut off, turn off

the manual gas valve and check the installation.

This installation must conform with below section

• "Air for Combustion and Ventilation" of the

National Fuel Gas Code, ANSI Z224.1/NFPA 54,

or Sections 8.2, 8.3 or 8.4 of Natural Gas and

Propane Installation Code, CAN/CSA B149.1, or

applicable provisions of the local building codes.

CAUTION

4.4 Venting (Exhaust)

The flue temperature of the water heater changes

dramatically with changes in operating water

temperature. If the water heater is installed in an

application where the set point is greater than

140°F(60°C), ambient temperature is elevated,

and/or installed in a closet/alcove, CPVC,

polypropylene, or stainless steel material is

required. If the system temperatures are unknown

at the time of installation, stainless, polypropylene

or CPVC material is recommended.

The LT Series is a Category IV appliance and may

be installed with PVC, CPVC or polypropylene that

complies with ULC-S636, ANSI/ASTM D1785 F441

(see Table 3) or a PVC or stainless steel venting

system that complies with UL 1738.

INSTALLATIONS IN CANADA require the use

of venting material certified to ULCS636. All Gas

vents connected to the water heater, plastic,

stainless steel or otherwise must be certified to

this ULC standard. Appropriate selection of vent

material is very important for proper performance

and safe operation of the water heater.

The flue temperature of the water heater changes

dramatically with changes in operating water

temperature. Therefore, it is necessary to assess

the application of the water heater to determine

the required certified vent class. If the water

heater is installed in an application where the

Summary of Contents for LT Series

Page 42: ...Page 42 4 20 Wiring Diagram...

Page 43: ...Page 43 4 21 Ladder Diagram...