Page 2

7

WARNING:

Open flame can cause gas to ignite and result in

property damage, severe injury, or loss of life.

NOTE

: The LT Series appliance and all other gas

appliances sharing the gas supply line must be firing at

maximum capacity to properly measure the inlet supply

pressure. The pressure can be measured at the supply

pressure port on the gas valve. Low gas pressure could

be an indication of an undersized gas meter, undersized

gas supply lines and/or an obstructed gas supply line.

SCHED 40 METAL PIPE CAPACITY FOR 1.50 SPECIFIC GRAVITY

UNDILUTED PROPANE

NOMINAL PIPE SIZE

@

11" W.C. INLET AND 0.5" W.C. PRESSURE DROP

SIZE

1/2"

3/4"

1"

LENGTH

MAXIMUM CAPACITY IN THOUSANDS OF BTU PER HOUR

20

200

418

787

40

-

287

541

60

-

231

434

80

-

197

372

100

-

175

330

NOTES:

1. Follow all local and national propane gas codes for line sizing and

equipment requirements. 2. Verify that inlet gas pressure remains between

4 and 13 inches of water column before and during operation.

Source: ANSI Z223.1-80 National Fuel Gas Code.

Table 7. Nominal Pipe Size, Propane

SCH 40 METAL PIPE CAPACITY FOR 0.60 SPECIFIC GRAVITY NATURAL GAS

NOMINAL PIPE SIZE

@

0.30" W.C. PRESSURE DROP

SIZE

1/2"

3/4"

1"

FT CUBIC FEET OF GAS PER HOUR

20

92

190

350

40

-

130

245

60

-

105

195

80

-

90

170

100

Table 8. Nominal Pipe Size, Natural Gas

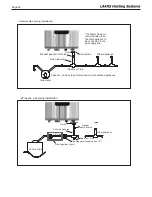

4.9 Gas Supply and Piping

Gas piping should be supported by suitable hangers or

floor stands, not the appliance.

Review the following instructions before proceeding with

the installation.

1. Verify that the appliance is fitted for the proper type

of gas by checking the rating plate. LT Series water

heaters will function properly at elevations up to

10,000 feet (3050 m). Refer to Section 4.12 for High

Altitude Settings.

2. Refer to Table 7, Table 8, and Table 9 for sizing

piping.

3. For minimum and maximum gas supply pressures,

see Table 10.

4. Run gas supply line in accordance with all applicable

codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of the

gas controls.

7. All threaded joints should be coated with piping

compound resistant to action of liquefied petroleum

gas.

8. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping during any

pressure testing of that system at test pressures in

excess of 1/2 PSIG (3.45kPa).

9. The unit must be isolated from the gas supply system

by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 PSIG

(3.45kPa).

10. The appliance and its gas connection must be leak

tested before placing it in operation.

11. Purge all air from gas lines.

12. Note if using 1/2" Gas line a maximum of 24

equivalent feet is allowed.

EQUIVALENT LENGTHS OF STRAIGHT PIPE FOR TYPICAL SCH 40 FITTINGS

NOMINAL PIPE SIZE

FITTING

1/2"

3/4"

1"

LINEAR FEET

90° ELBOW

3.6

4.4

5.2

TEE

4.2

5.3

6.6

Table 9. Equivalent Pipe Lengths

Summary of Contents for LT Series

Page 42: ...Page 42 4 20 Wiring Diagram...

Page 43: ...Page 43 4 21 Ladder Diagram...