Endurance

Page 31

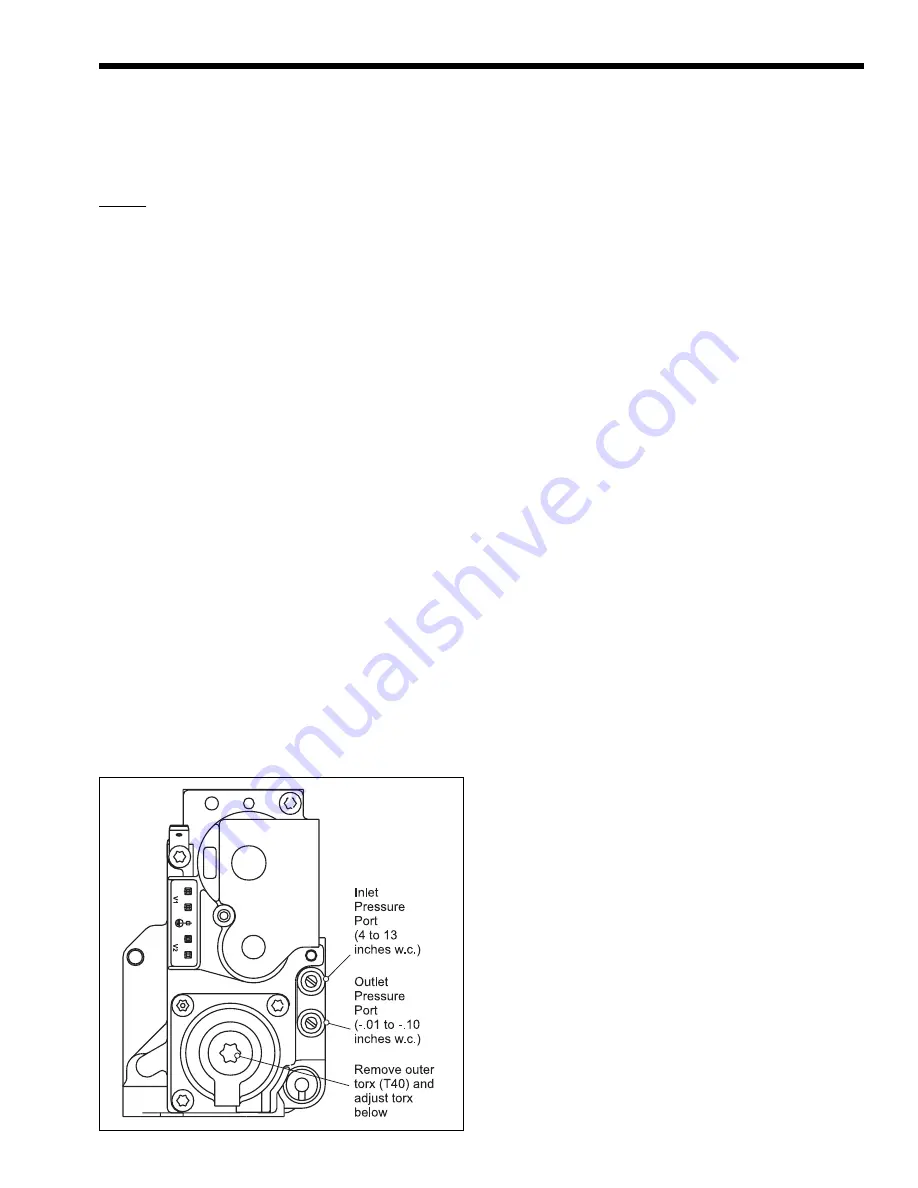

Figure 35. Gas Valve.

8.11Thermostatic Union (EDP/EDN)

The thermostatic union is a 1¼" NPTF union

which must be mounted at the flow outlet to control

boiler temperature. The union must be installed so that

union nut is on the boiler side of the connection. This

insures that the thermostat is properly positioned with

its spring facing up, toward the system. The element

has small bypass holes that allow some water to flow

into the system at all times. When the boiler first starts

and the element is closed, boiler water is re-circulated

back to the return until the supply water reaches 160°F

(71°C). The element then modulates open. If the

temperature does not exceed 150°F (66°C) within two

minutes after firing, the element is not functioning

properly. To replace the element, shut off and drain the

section of the system adjacent to the thermostatic

union. Open the union and replace the element with a

new one. The element should be installed so that its

spring and actuator are facing the system side (up).

Close the union, open the valves, refill and bleed the

system. Ensure that air is venting from the air vent on

top of the boiler chamber and it is left operational.

Restart boiler.

8.12Cleaning the Boiler Coil

The Endurance is equipped with a premixed

combustion system. This type of combustion system

does not create free carbon (soot) except in very rare

instances and therefor the combustion chamber coil

will probably never need cleaning. If cleaning is

required, proceed as follows: valve off the boiler,

switch off the electrical power at the disconnect

switch, drain 1-2 gallons (4-8L) of water from the

boiler drain, remove the flue assembly from the top of

the boiler, remove the pump flange bolts from the top

pump flange, disconnect the sensor wires from the

sensors (boiler flow, return and safety limit), undo the

union nut from the boiler flow manifold, and remove

the four (4) screws from the bottom gas valve flange.

Unplug the blower and the ignitor. Remove the bolts

from the blower and pull the blower out. The boiler

assembly may now be removed from the jacket. After

removal of the boiler assembly from the jacket,

remove the ignitor and the burner from the combustion

chamber. Then, remove the four (4) long screws that

secure the top and bottom pans. Remove the air vent

and the top pan. Remove the insulation retainer and

the coil cover insulation. Clean the boiler coil with a

wire brush and vacuum debris from the combustion

chamber (avoid hitting the ignitor or the flame sensor

with the brush or vacuum hose because they are

fragile).

After cleaning, assemble the parts in the reverse

order, open isolation valves and bleed air from the

boiler and the system. Follow the lighting instructions

and start the boiler. Check operation.

SECTION 9

Servicing.

9.1 Sequence of Operation

Figures 32 and 33 depict the flow paths and

temperature sensor locations for the space heating,

EDP/EDN, and the combined space heating and

domestic water heating, EBP, appliances.

The model EDP/EDN modulating boilers are

cold start boilers that will start only on a call for heat

from a room thermostat or zone control contact.

During normal operation the boiler control will

display the supply temperature. The Endurance call

for heat may come from any of the following:

1.

Heating call for heat (TT) from thermostat, end

switch, etc.

2.

Domestic water call for heat from domestic water

flow switch (EBP only).

3.

Tank charge call for heat, when transfer tank is

less than 40°F (22°C) below the Off Point (EBP

only).

On a call for heat the following sequence will

occur.

1.

For EBP units only, the anti-condensing valve is

put in the proper position.

2.

The internal pump starts.

3.

Blower pre-purge begins (7-seconds).

4.

Boiler control sends the signal to the ignition

control that there is a call for heat.

5.

After a self-check and 15 second ignition control

“pre-purge”, the ignition control begins the

ignitor warm-up period.

6.

After the ignitor is warmed up, the gas valve

terminal on the ignition control is energized for

the 10-second trial for ignition.