Endurance

Page 11

(21mm per meter). Be sure to take this into

consideration when choosing the vent terminal

location.

For applications requiring vertical venting

through a roof, the same limitations for length and

fittings apply (see Table 2). Vertical vents greater than

7 feet (2.1m) in length must use a condensate trap.

When vertical vent systems have horizontal

components, they must have a condensate drip tee in

the offset. All horizontal portions of the vent system

must slope a minimum 1/4" per foot toward the

condensate drip tee. Laars vertical vent kit and

individual venting components have condensate tees

that work in a vertical vent system, and therefore it is

not necessary to have an offset in a vertical vent

systems that use these parts.

The vertical vent terminal must be placed such

that the bottom of the vent cap is at least 2-feet (0.6m)

above any structure (such as the peak of a roof or

adjacent wall) within 10 feet (3.0m), and must be at

least 3 feet (0.9m) above where the vent pipe exits the

roof (see Figure 12).

Laars offers 3" vent parts for non-concentric

venting, including an in-line condensate tee and vent

caps for vertical venting. See Figure 13 for 3" vent

parts, and Figure 15 for an example of the inline

condensate in a vertical vent system.

IMPORTANT NOTE REGARDING ENDURANCE

VENTING:

Regardless of the venting arrangement

being used, the flue gas vent material used with the

Endurance MUST be

stainless steel

special gas

vent listed to U.L. Standard 1738 and U.L.C.

Standard 636. Endurance flue gases must

never

be

vented into a masonry chimney or vented with B-vent

or other galvanized vent material. Endurance units

are

not

permitted to be common vented with any

other appliance(s), including other Endurance

appliances.

2.3 Air Source For Combustion

(when not ducted to the Endurance)

When using Category IV venting methods the

appliance draws all combustion air through its top and

from the adjacent space. When locating the appliance

in unconfined spaces in buildings, infiltration may be

adequate to provide air for combustion and

ventilation. However, in buildings of unusually tight

construction, or when locating the appliance in a

confined space, additional air should be provided and

the guidelines below must be followed:

2.3.1 Air From Inside the Building

The following method shall be used to size the

air openings for boilers that are getting all of their

combustion air from inside the building.

The confined space shall be provided with

two

permanent openings communicating directly with

other spaces of sufficient volume so that the combined

volume of all such spaces meets the criteria for an

unconfined space. The total input of all gas utilization

equipment installed in the combined spaces shall be

used to determine the required minimum volume.

Each

opening shall have a minimum free area of not

less than 1 in.

2

/1000 Btu/hr (220 mm

2

/kW) of the total

input rating of all gas utilization equipment in the

confined space, but not less than 100 in.

2

(645 cm

2

).

One opening shall commence within 12 in. (30 cm) of

the top, and one opening shall commence within 12 in.

(30cm) of the bottom, of the enclosure. The minimum

dimension of air openings shall be not less than 3 in.

(8 cm).

2.3.2 All Air From Outdoors

When all air is provided from outdoors, but not

ducted directly to the Endurance, the following

methods shall be used to size the air opening(s).

a.

Two

permanent openings, one commencing

within 12 in. (30 cm) of the top and one

commencing within 12 in. (30 cm) of the bottom,

of the enclosure shall be provided. The openings

shall communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

a1. Where directly communicating with the

outdoors or where communicating to the

outdoors through vertical ducts,

each

opening shall have a minimum free area of

1 in.

2

/4000 Btu/hr (550 mm

2

/kW) of total

input rating of all equipment in the

enclosure.

a2. Where communicating with the outdoors

through horizontal ducts,

each

opening

shall have a minimum free area of not less

than 1 in.

2

/2000 Btu/hr (1100 mm

2

/kW) of

total input rating of all equipment in the

enclosure.

b.

One permanent opening, commencing within 12

in. (30 cm) of the top of the enclosure, shall be

permitted where the equipment has clearances of

at least 1 in. (2.5 cm) from the sides and back

and 6 in. (16 cm) from the front of the appliance.

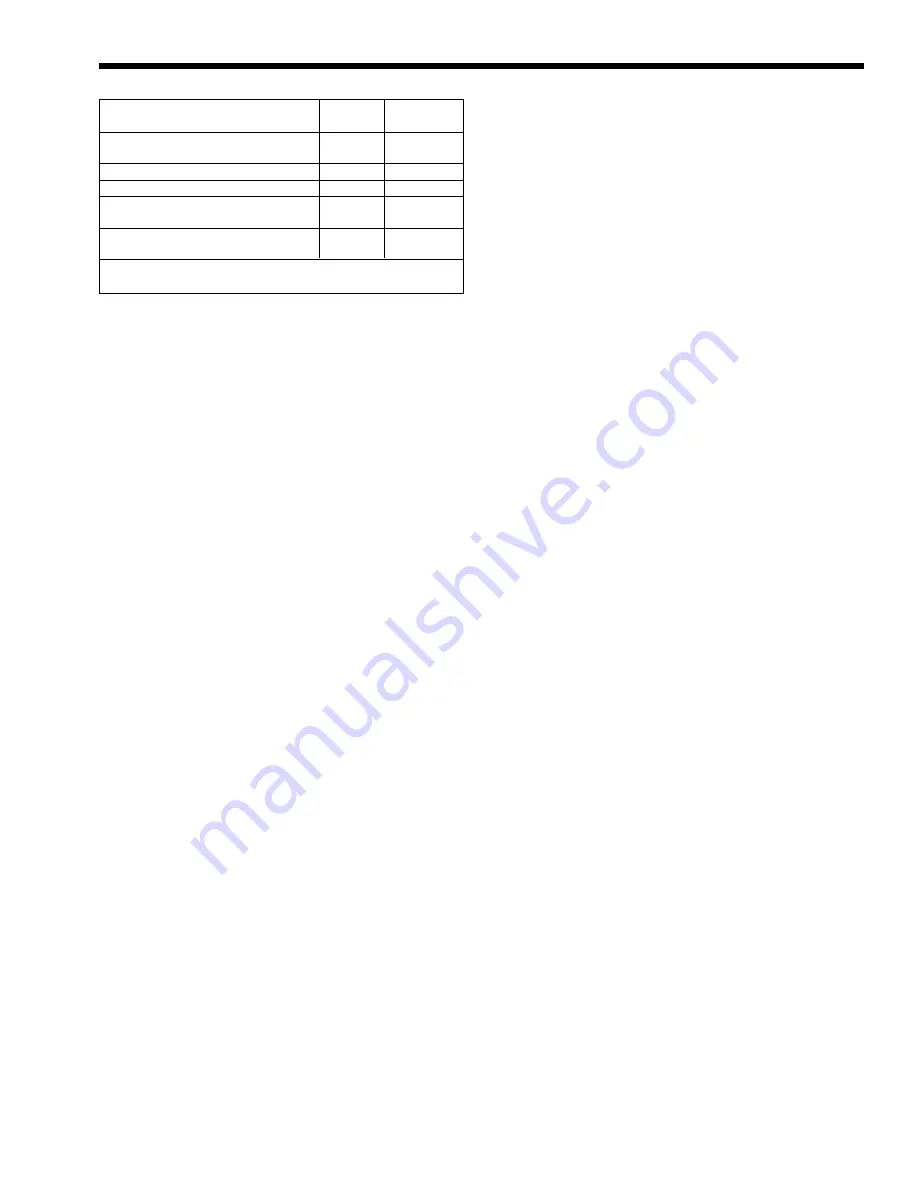

Minimum clearance from

combustibles (vent) U.S.*

3"

8cm

Minimum clearance from

combustibles (vent) Canada

6"

15cm

Max. flue gas temp.

325°F

163°C

Max vent pressure

1.5" w.c.

0.4kPa

Max. equivalent ft. of 3" venting (any

50

15

combination of horizontal or vertical)

equiv. feet

equiv. meters

Max. equivalent ft. of 4" venting (any

100

30

combination of horizontal or vertical)

equiv. feet

equiv. meters

*Note: To use 3" (8cm) clearance, the vent must be open on at

least one side. If fully enclosed, clearance is 6" (15cm)

Table 2. Category IV Vent Parameters.