FOCOLARI in ghisa

22

6097000 Rev.12 – EN

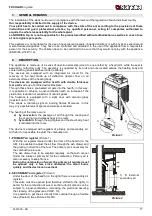

c) Each pipe must not exceed 2m of length for natural ventilation and 4m for forced ventilation; it must be insulated

with insulating materials to avoid noise and dispersion of heat.

d) The openings must be positioned at a height not lower than 2 m from the floor to avoid that hot air at output meets

people.

e) The canalization pipes must all have an equal length in order to avoid different quantities of air distributed from

each outlet.

(see Picture 12 -Picture 13)

7.

CONNECTION TO THE FLUE / AIR FOR COMBUSTION (external air intake)

The connection to the stack must be performed with stiff pipes in aluminized steel with a minimum thickness of 2 mm

or in 316 stainless steel with a minimum thickness of 1 mm.

It is forbidden to use metallic pipes or pipes in asbestos cement since they jeopardize the safety of the fitting

itself, considering that they are subject to tears or breaks resulting in leaks of smoke.

The exhaust pipe must be air-tight fastened to the stack and can have a maximum inclination of 45°; th is to avoid

excessive deposits of condensate produced in the initial start-up phases and/or the excessive gripping of soot and

moreover it avoids the slowing down of the smokes at output.

The failed tightness of the connection can cause the malfunction of the device.

The internal diameter of the connection pipe must be equal to the external diameter of the smokes stub pipe of the

device. This is assured by the pipes complying with DIN 1298.

The depression in the stack should be - 14 Pa (=1.4 mm of column of water).

The measurement has always to be carried out with hot device (rated thermal performance).

When the depression exceeds 17 Pa (1.7 mm of column of water), it is necessary to reduce the same by installing an

additional draught regulator (butterfly valve).

IMPORTANT: When using metallic pipes, they must be insulated with proper materials (coatings in insulating

fibers resistant up to 600°C) in order to avoid det erioration of walls or of the counter-hood.

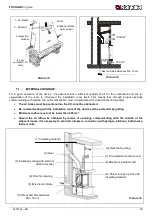

It is necessary to ventilate continuously the space included between the upper part, the sides of the device and the

deflector of the fire-proofing material of the hood.

For this reason, it is necessary to foresee an intake of air from the bottom (intake of fresh air) and a high output

(output of hot air).

The spaces foreseen for the circulation of air indicated in Picture 14 - Picture 15 represent the minimum

requirements:

Top:

Minimum opening 1000 cm

2

Base:

Minimum opening 750 cm

2

In this way, the following targets are achieved:

•

a greater safety

•

an increase of the heat created by air circulation around the device.

The heat vent grating (Picture 16 pos. 6) has to be installed on the upper part of the hood at about 20 cm from the

roof. This must always be installed since its function is that of letting the heat collected within the hood

(overpressure) flow out into the room.

Picture 12

Picture 13