2FB/2FC-2.0

2-4-18

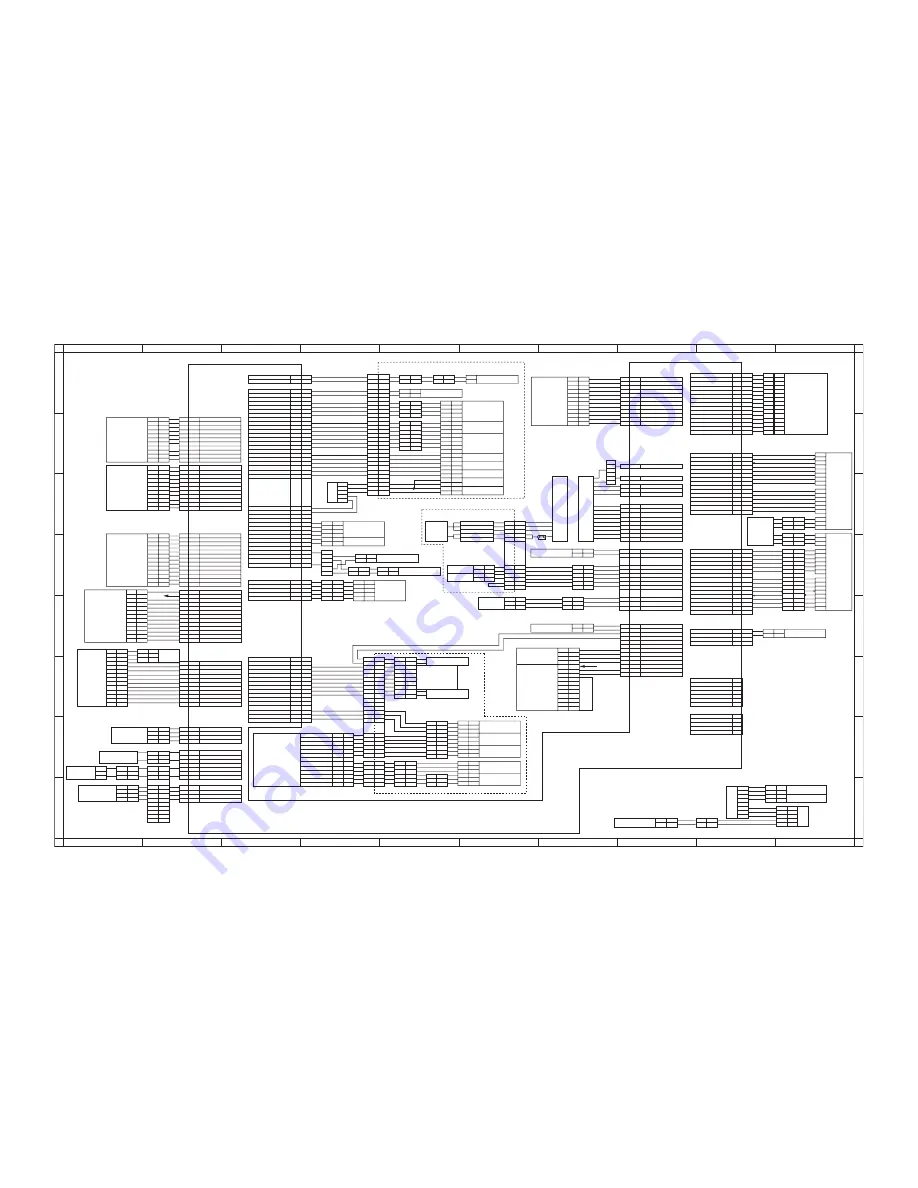

Wiring diagram No.4

A

B

C

D

E

F

G

H

I

J

A

B

C

D

E

F

G

H

I

J

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

YC8

YC7

YC1

YC5

YC2

YC14

YC9

YC11

YC3

YC12

YC17

YC15

YC13

YC22

YC6

YC19

YC4

YC20

YC6

YC23

YC10

YC18

3

1

RCSW

12

12

3

10

10

11

11

1

2

3

2

DUPPWB

T COUNT SET SIG

4

1

GND

REM

3

2

2

2

1

1

24V

1

4

2

3

A2

DLP FAN F REM

DLP FAN REM

2

1

2

3

3

1

A3

FIX TH M SIG

A3

A4

A5

A6

B1

B2

B3

B5

B4

B8

R24V

5V

4

5

1

7

DCPS

PWB

LSU-DATA

C1

C3

C2

C2

C3

C1

B7

3

1

2

3

13

3

1

14

1

2

PM

5

A1

3

5

7

B6

2

C3

5

4

5

6

4

3

2

1

2

1

8

9

13

14

2

1

10

1

B13

A6

A5

B1

A7

A2

A1

A8

A8

A1

A13

B8

A7

A6

A6

A10

B11

A10

A11

B4

B8

B6

B6

B5

B7

DUPPWB

YC2

DUPPWB

YC2

DKPWB

YC2

DKPWB

YC2

CSPWB

YC2

DUP SDI

DUP SDO

SGND

A8

A4

8

2

5

2

1

1

17

19

19

6

18

2

2

1

7

1

1

2

1

2

1

2

1

8

9

9

20

2

5

6

7

4

1

1

1

2

20

25

25

3

3

4

29

2

4

A8

3

2

2

1

4

B3

B2

B4

A1

B6

B12

B7

B13

B11

4

2

3

3

3

3

2

8

4

8

9

1

6

6

5

1

2

2

3

3

1

1

A14

A11

A13

A12

A3

4

5

2

3

A6

6

5

A5

3

1

2

1

A4

FS SOL RTN

TRF REM

PGND

R24V

R24V

FEED SHIFT FAN REM

R24V

N.C

N.C

FS SOL PUL

FS SW

16

16

4

12

14

10

8

11

B2

A10

A9

A8

A7

B1

2

14

B5

4

B3

5V

B11

SGND

10

11

10

11

12

1

N.C

3

TRF -CNT

N.C

RxD

SGND

5V

5V

REG SW

6

SGND

3

2

1

2

3

A9

A10

7

7

B7

B8

1

B6

7

3

1

2

SGND

SCK

ERSTN

1

SGND

2

DISPOSL SIG(I)

B3

MAIN MOT ALM

MAIN MOT REM

CONT SET SW

5

B12

B9

TRF INV

TRF +CNT

1

R24V

2

8

11

13

4

12

10

1

7

15

3

4

4

3

2

1

2

GY

RD

GY

RD

2

CL

CLC

DEVS

DEVC

CLM

PCLM

IFFM

DEVFM2

DEVFM1

1

1

9

8

7

2

9

6

7

8

2

1

2

5

12

1

1

2

13

2

R24V

3

5

10

14

18

12

6

A5

DRUM HEAT REM

CL LAMP REM

CL EEPROM SET

SGND

CL EEPROM DATA

REG MOT REM

REG MOT MODE

FEED MOT REM

B3

A3

DUP SEL(O)

N.C

SGND

A5

A9

A4

A1

A2

A12

A3

A2

A1

B1

A3

B2

B9

B5

B4

B5

B7

A11

B10

B6

B8

B7

5

5

6

6

1

1

2

1

VPP

WRSI

3

1

3

5

4

6

7

9

TxD

2

2

3

5

N.C

4

2

FSSOL

FSSW

ESW

FSW1

RSW

3

3

2

RELAY REM

ZEROCROSS REM

1

RIGHT COV SORCE

2

CS SDI

3

24

27

FUSER MOT REM

PGND(N.C)

24

3

27

1

26

29

POTENTIAL SENS SIG

PGND

PGND

PGND

B2

B10

R24V

B1

B11

FUSER MOT ALM

A12

B10

A13

26

SGND

28

31

A13

B1

PGND

B9

B3

B8

B4

A3

A4

A7

A6

A6

A11

A10

A9

A8

15

2

2

B9

REG MOT HLD

B6

REG SW

FEED MOT CLK

1

3

4

6

7

4

4

14

A2

A7

A8

A4

A5

A9

A3

A5

5

2

4

10

12

4

16

4

11

10

3

3

11

10

2

EG SDI

DLP PLS

DLP CONT

4

1

PTC REM

3

EG SDO

EG SDIR

3

EG SBSY

SGND

5

EG IRN

OUTPEN

7

PVSYNC

R5V

SGND

2

PTC ALM

1

15

14

13

EG SGLK

1

PGND

RELAY SOURCE

R24V

SGND

3

S5V

R24V

DLP AC CNT

4

11

11

4

8

9

7

4

2

12

14

3

12

5

11

6

10

13

15

5

8

10

6

7

8

9

10

9

4

G CONT

DLP DC REM

10

9

8

6

DLP AC REM

5

LDON

A2

A1

A2

A10

A1

A11

2

18

6

5

18

16

17

1

1

DUP RDY(I)

DUP SCLK(O)

13

14

16

CL EEPROM CLK

2

7

A9

DUP PAUSE

7

12

16

12

10

1

A4

A1

A6

A7

FEED A SW

EJECT SW

9

8

6

5

1

5

7

3

11

2

3

6

5

11

4

1

4

11

12

12

3

12

8

9

MC ALM

MC REM

10

PGND

13

M HEATER REM

L HEATER REM

15

1

2

5

LSU-LOAD

DF SET

3

3

13

24V

2

14

1

15

2

3

1

OP SDO (DF)

OP SDI (DF)

CS HEATER REM

3

1

2

3

1

2

1

2

1

2

SG (DF)

SG (SF)

3

2

1

5V

3

4

5

6

7

8

9

10

11

12

13

14

15

1-5

1-4

1-3

2-4

2-3

2-2

2-1

2-12

2-11

2-10

2-9

14

SG (SF)

7

7

8

8

SG (SF)

6

6

SG (DF)

9

9

8

3

5

6

4

7

11

13

S HEATER REM

4

WEBSOL

HVPWB

ACPSPWB

DCPSPWB

5

R24V

FIX WEBSOL REM

PFAN REM

1

3

7

6

2

5

1

3

7

6

2

5

1

3

2

4

5

1

9

6

1

6

2

5

WRSO

11

5V

3

1

5V

3

2

6

5

4

4

HEATER LIVE 2

3

3

9

13

2

7

7

5V

7

D HUMID SENS

3

HUMS1

FMDPWB

(B)

(A)

(A)

(C)

(B)

B3

2

5

1

1

1

DUPFM

FSFM

1

1

2

10

1

2

12

4

3

10

8

9

2

9

11

FRCSW

A14

A11

A12

MP TRY SW SIG

A13

CS RDY (I)

3

4

4

4

4

1

1

2

1

2

2

3

3

4

4

1

HUMS2

1

2

2

3

3

1

1

2

2

6

6

1

B8

B5

B7

B2

B3

B6

B3

B7

A4

A3

B4

B10

A1

B9

B11

B1

A9

A7

A6

A5

A8

5

4

4

5

1

1

1

1

2

2

4

3

2

3

3

CFM4

1

1

3

2

1

DRHPWB

2

1

1

2

2

1

1

2

SFM

2

1

1

2

2

1

1

2

DEVDFM

2

1

1

2

LSUFM

A3

4

4

5

1

A2

5

2

3

3

2

1

2

2

3

4

A4

4

2

1

1

1

1

2

A5

B4

3

2

2

4

3

3

3

3

1

2

2

3

1

5

SGND

3

CONT SENS

MP MOT REM

SGND

EJECT SW

1

1

8

9

A12

7

7

B10

B9

B14

A11

12

6

6

B5

5

B12

3

5

4

5

A1

A3

6

THVPWB

5

2

A2

1

9

B4

4

5

B13

B1

7

3

2

2

B14

A4

A5

5

2

1

B8

1

2

A7

B9

B10

1

2

2

1

1

4

3

9

7

D TEMP SENS

TFR MOT ALM

SGND

SGND

TFR MOT REM

15

SGND

MP MOT HLD

15

SGND

FAN STOP

R24V

FEED MOT MODE

FEED MOT HLD

SG (DF)

MP MOT CLK

2

1

DK SDI

DK SDO

SG (DF)

SG (DF)

1

1

COOL FAN3 REM

LSU FAN REM

28

C6

PTS

(C)

CFM3

FH-L

FH-M

FTS

FH-S

FTH-M

FTH-S

SBESW

C4

OP SCLK (DF)

DF RDY

9

DF SEL

SI SEL

SI RDY

SG (DF)

12

6

7

8

10

FEED B SW

MP SOL PULL

2

4

2

2

1

2

1

3

2

4

1

5

4

5

3

DK RDY(I)

31

32

32

30

30

5

DK SCLK(O)

MP SOL RTN

PGND

DK SEL(O)

PLG CLK

B10

B4

B6

B9

B4

B5

B8

B6

B9

B5

B6

B7

B7

B8

B8

B1

3

10

2

9

4

14

10

11

1

13

B10

B11

B3

B2

B5

9

8

7

6

B3

B2

B4

5

9

A12

A11

A3

B2

A8

A5

B11

A9

A10

A4

A9

A5

A7

A7

A4

3

1

1

3

3

PLG READY

PLG REM

A6

A8

A10

4

MP SET SW SIG

MP PSD SW SIG

A9

A3

A2

5

CS PAUSE

B12

B1

2

3

B13

11

3

4

8

4

3

9

12

B11

B3

12

B12

B10

B11

B13

B7

B9

B5

B13

B1

B12

B2

6

2

B4

7

6

4

8

6

WTS

11

PGND

1

8

2

CS SDO

4

3

3

4

11

2

1

4

10

8

2

2

GND

24V

RIGHT COV SIG

MP DIG1

K.CARD REM

SET SIG

FRONT COV SORCE

1

1

5

10

9

9

SGND

5V

PGND

PGND

PGND

1

6

4

7

11

3

6

4

5

1

2

2

5

MP DIG2

CS SCLK (O)

3

1

5

HUMID SENS SIG

TEMP SENS SIG

3

5

6

3

MP DIG0

5V

8

A6

A2

OP SDO (SF)

SG (SF)

OP SCLK (SF)

SGND

PGND

SGND

STOP (SF)

SGND

5

6

6

SG (SF)

SGND

FIX TH S SIG

SB EJ SW SIG

CONVEY U SET SIG

8

7

7

A10

A2

REG MOT CLK

B11

A11

A10

B2

B10

5

6

7

10

11

22

22

10

11

21

12

12

23

23

24

24

21

5V

15

23

9

15

DLP EEPROM DATA

13

DLP EEPROM CLK

9

SGND

13

22

19

3

23

22

3

19

1

11

17

CL MOT MC FWD

CL MOT MC REV

11

17

DLP EEPROM SET

5V

20

6

PGND

CL MOT PTC REV

CL MOT PTC FWD

20

8

6

1

4

2

4

2

8

IMAGE FAN REM

21

DLP SENS SIG

DLP FAN R REM

SGND

21

13

8

14

9

10

11

12

2

SG (SF)

SG (SF)

1

1

SG (SF)

2

2

3

3

4

4

5

5

A5

A6

A4

12

4

11

5

10

6

9

7

8

8

7

A2

A1

B8

B7

10

B6

10

B5

9

6

11

4

12

3

10

5

11

B4

B3

B2

B1

SF SEL

13

2

14

14

1

14

15

OP SDI (SF)

11

SF RDY

12

12

13

13

N.C.

15

8

1

7

2

COOL FAN1 REM

COOL FAN4 REM

MP MOT CWB

MP MOT MODE

A13

A11

14

10

CS SEL (O)

2

2

1

3

3

1

6

5

2

7

14

LSU -CLK

4

4

3

3

FEED A SW

4

6

1

2

PGND

FRONT COV SIG

HEATER LIVE 1

1

2

1

1

3

2

4

5

4

6

4

3

C2

C1

2

1

3

2

1

3

WE

WE

WE

RD

BK

BK

BK

BK

BK

BK

EPWB

8

8

9

9

14

15

8

11

1

1

CFM1

CFM2

1

2

2

2

1

2

4

1

1

2

5

3

2

3

4

5

9

10

13

MPWB

YC1

Key counter

Optional

finisher

Optional

side

feeder

Total counter

Paper conveying unit

Feedshift unit

Fuser unit

Image formation unit

Summary of Contents for KM-6030

Page 1: ...SERVICE MANUAL Published in March 2006 842FB114 Rev 4 KM 6030 KM 8030...

Page 4: ...This page is intentionally left blank...

Page 10: ......

Page 82: ...2FB 2FC 2 0 1 4 13 This page is intentionally left blank...

Page 90: ...2FB 2FC 3 1 4 19 This page is intentionally left blank...

Page 110: ...2FB 2FC 3 1 4 37 This page is intentionally left blank...

Page 184: ...2FB 2FC 4 1 5 25 This page is intentionally left blank...

Page 267: ...2FB 2FC 3 1 6 30 This page is intentionally left blank...

Page 288: ...2FB 2FC 4 1 6 51 This page is intentionally left blank...

Page 323: ...2FB 2FC 2 0 1 6 84 This page is intentionally left blank...

Page 463: ......