MAINTENANCE

70

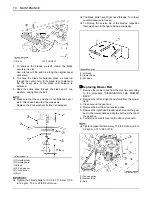

3. To sharpen the blades yourself, clamp the blade

securely in a vise.

Use a large mill file and file along the original bevel

until sharp.

4. To check the blade for balance, place a small rod

through the center hole. If the blade is not balanced,

file the heavy side of the blade until balance is

achieved.

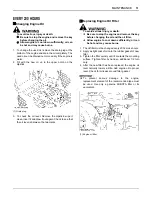

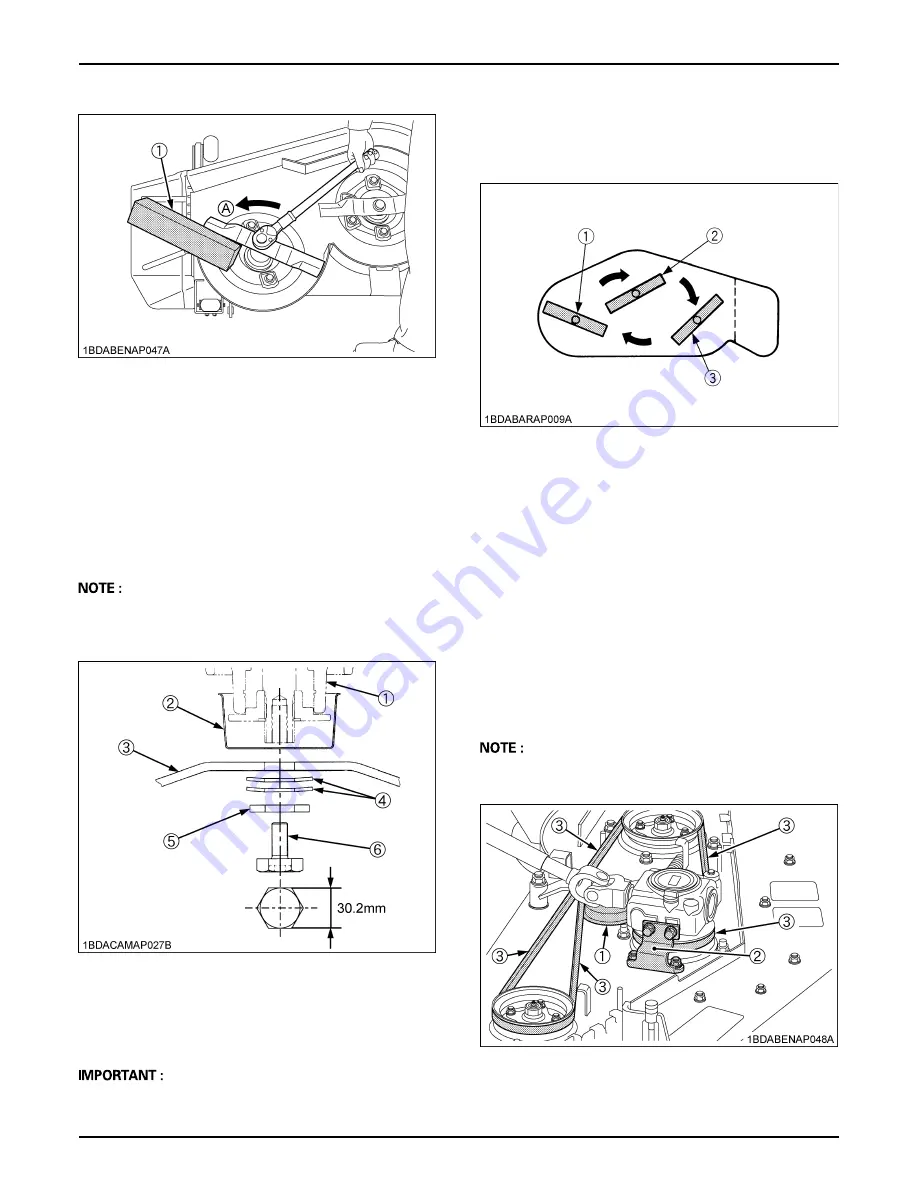

5. Pass the spline boss through the blade and 2 cup

washers, and tighten the bolt.

A

Make sure that the cup washer is not flattened out or

worn; this cause blade to slip excessively.

Replace the 2 cup washers if either is damaged.

A

Tighten the 3 blade bolts to 102.9 to 117.6 N-m (10.5

to 12 kgf-m, 75.9 to 87 lbf-ft) of torque.

A

The blade bolts have Right hand threads. Turn them

counterclockwise to loosen.

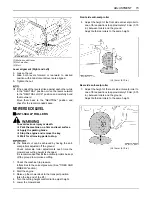

A

To prolong the service life of the blades, reposition

them as shown in the figure below periodically.

B

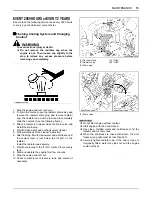

Replacing Mower Belt

1. Remove the mower deck from the machine according

to the procedure "DISMOUNTING THE MOWER

DECK".

2. Remove the left and right hand shield from the mower

deck.

3. Clean around the gear box.

4. Remove the belt from the tension pulley.

5. Remove the right hand bracket which mounts the gear

box to the mower deck and slip the belt over the top of

the gear box.

6. To install a new belt, reverse the above procedure.

A

Tighten bracket bolts securely 77.5 to 90.2 N-m (8.0 to

9.2 kgf-m, 57.1 to 66.5 lbf-ft).

(1) Block

(A) "LOOSEN"

(1) Spindle holder

(2) Spindle guard

(3) Blade

(4) 2-Cup washer

(5) Lock washer

(6) Bolt

(1) LH blade

(2) Center blade

(3) RH blade

(1) Tension pulley

(2) Bracket (RH)

(3) Belt

Summary of Contents for ZD1011-AU

Page 15: ...SAFE OPERATION 8 7 DANGER WARNING AND CAUTION LABELS ...

Page 16: ... 9 SAFE OPERATION ...

Page 17: ...SAFE OPERATION 10 ...

Page 18: ... 11 SAFE OPERATION ...

Page 21: ...SERVICING OF MACHINE 2 1 ROPS serial number ...

Page 69: ...50 MAINTENANCE PERIODIC SERVICE CHART LABEL 1 Part No K3411 6552 5 ...