30/ENGINE - WORK ON THE INDIVIDUAL PARTS

137

–

Repeat the operation on the opposite side.

–

Ensure that the new crankshaft bearing inner race is flush.

Info

After replacing the crankshaft bearings, the crankshaft end play must be

measured.

20.8

Changing the connecting rod, conrod bearing and crank pin

302917-10

Main work

–

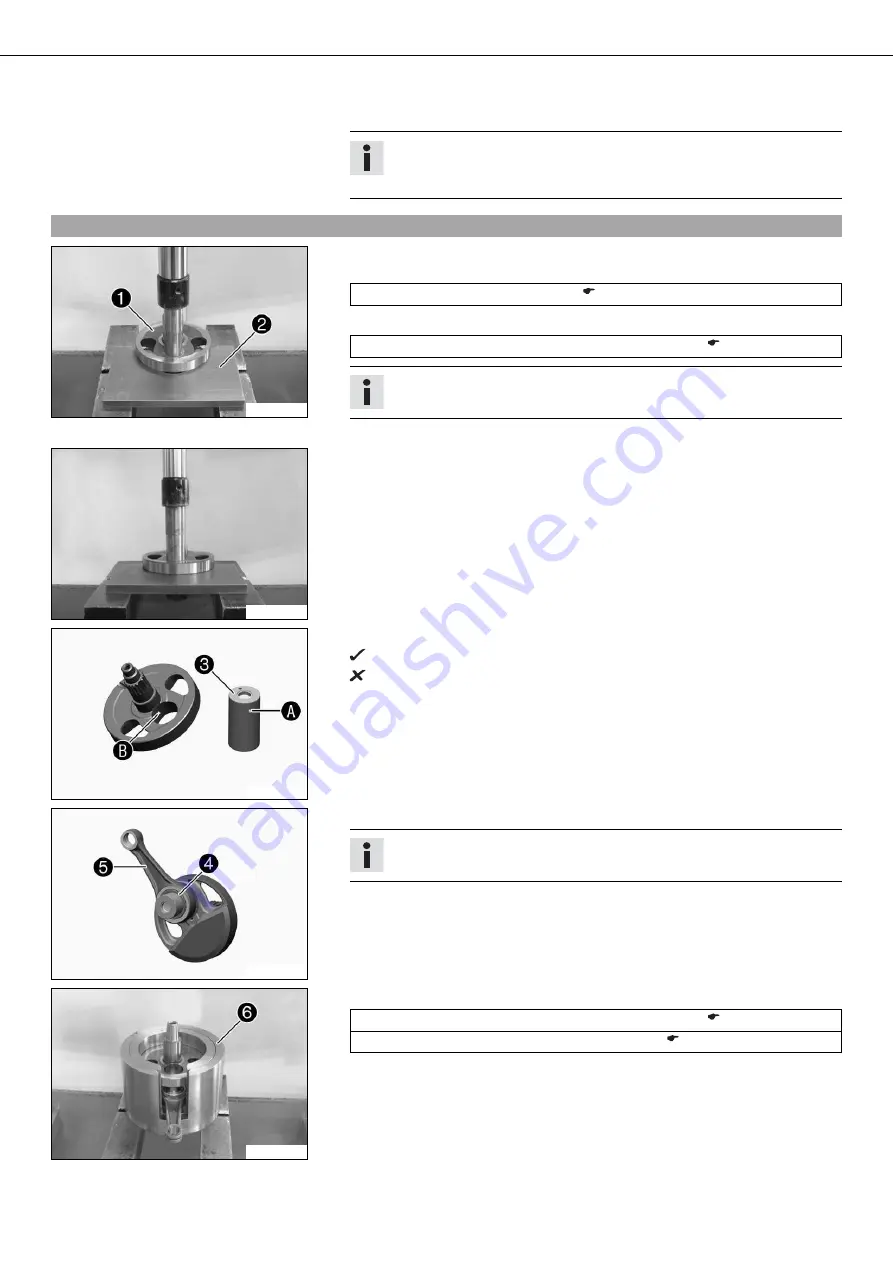

Position crankshaft

1

in the press using special tool

2

.

Extrude plate, base (77229009000) (

–

Press the crank pin with the special tool out of the upper crank web.

Pressing device for crankshaft, complete (75029047000) (

Info

Hold the lower crank web.

–

Remove the connecting rod and bearing.

302918-10

–

Press the crank pin out of the lower crank web.

302912-10

–

Press in the new crank pin

3

as far as possible.

Oil hole

A

is aligned with oil hole

B

.

If the oil holes are not correctly aligned, the conrod bearing will not be sup-

plied with oil.

–

Use compressed air to check that the oil hole is clear.

302913-10

–

Mount the new bearing

4

and connecting rod

5

.

Info

Thoroughly oil the bearing.

302920-10

–

Position special tool

6

on the press.

Pressing device for crankshaft, complete (75029047000) (

Insert for crankshaft pressing tool (77229008000) (

–

Insert the crank web with connecting rod and bearing. Position the second crank

web.