KAH Operation & Maintenance Guide

Page: 65 of 88

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | [email protected] | www.krueger-hvac.com

SECTION 4 - SERVICE & REPAIR

Standard Mounting

1. Install the shaft key. If a key was furnished with the

bushing, use that key.

2. Install the bushing on the clean shaft, flange end first.

If the bushing will not freely slide onto the shaft, insert

a screwdriver or similar object into the flange sawcut

to act as a wedge to open the bushings bore.

3. If using the set screw, tighten it enough to prevent the

bushing from sliding onto the shaft.

4. Slide the sheave into position on the bushing, aligning

the drill holes in the sheave with the tapped holes in

the bushing flange.

5. Loosely thread the caps crews with the lock washers

into the assembly.

Reverse Mounting

1. With large end of the out, slide the sheave onto the

shaft as far as possible. Install the shaft key.

2. If a key was furnished with bushing, use that key.

3. Install the bushing onto the shaft so that the tapered

end will mate with the sheave.

4. If using the set screw, tighten it enough to prevent the

bushing from sliding onto the shaft.

a. Pull the sheave up onto the bushing, align the

drilled holes in the bushing flange with the tapped

holes in the sheave.

b. Loosely thread the cap screws with lock washers

into the assembly.

Using a torque wrench, tighten all the cap screws evenly

and progressively in rotation to the torque value as

shown in Table 16 (right). There must be a gap between

the bushing flange and sheave hub when installation is

complete.

Adjusting Sheave

1. Before belts are installed, check alignment as

described in Section 4.

2. If adjustment is required, measure the space between

the straight edge and the sheave.

3. Follow steps 2 through 5 under Removing Sheave in

this section. Move the bushing in the proper direction

the distance measured.

4. Proceed with the instructions in Installing Sheave in

this section.

5. Tighten all set screws according to the values in Table

17 (right).

CAUTION -

Excessive wedging will split the

bushing.

Do not tighten the set screw to standard torque

values at this time.

Do not use the lubricant on the cap screws.

CAUTION -

Do not over torque. Do not attempt to

close the gap between the bushing flange and the

sheave hub.

CAUTION -

The tightening force on the screws is

multiplied many times by the wedging action of

the tapered surface. If extreme tightening force

is applied, or if a lubricant is used, bursting

pressures will be created in the hub of the mating

part.

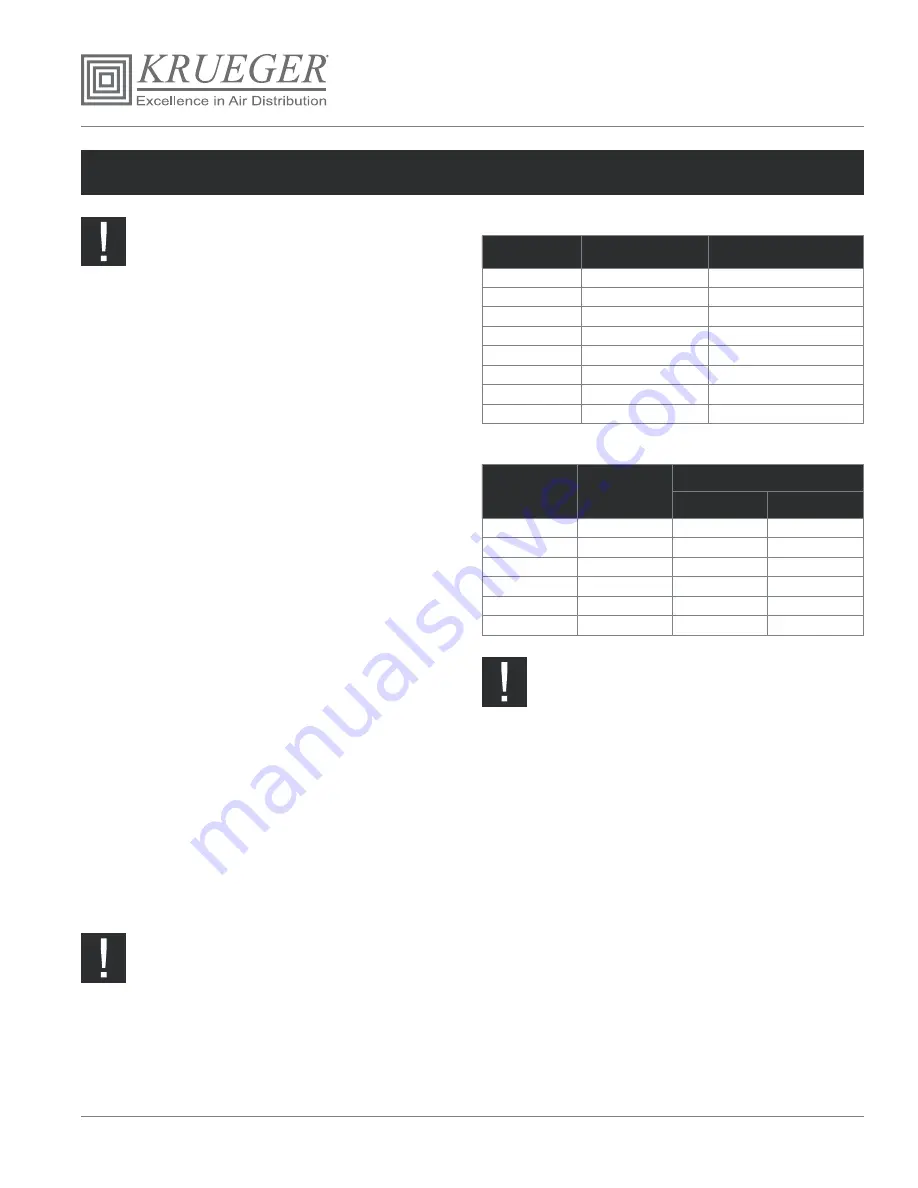

TAPERED

BUSHING

SIZE AND THREAD

OF CAP SCREW

FT-LB TO APPLY WITH

TORQUE WRENCH

QT

1/4 X 1

9

JA

NO. 10-24

5

SH-SDS-SD

1/4-20

9

SK

5/16-18

15

SF

3/8-16

30

E

1/2-13

60

F

9/16-12

110

J

5/8-11

135

TABLE 16 - CAP SCREW TORQUE VALUES

SET SCREW

DIAMETER

HEX WRENCH

SIZE ACROSS

FLATS

MIN. RECOMMENDED TORQUE

IN-LB

FT-LBS

1/4

1/8

66 - 85

5.5 - 7.08

5/16

5/32

126 - 164

10.5 - 13.7

3/8

3/16

228 - 296

19.0 - 24.7

7/16

7/32

348 - 452

29.0 - 35.7

1/2

1/4

504 - 655

42.0 - 54.6

5/8

5/16

1104 - 1435

92.0 - 119.6

TABLE 17 - SET SCREW TORQUE VALUES