Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | [email protected] | www.krueger-hvac.com

KAH Operation & Maintenance Guide

Page: 40 of 88

SECTION 3 - MAINTENANCE (CONTINUED)

ALIGNING SHEAVES

CAUTION -

An incorrectly aligned sheave can substantially shorten belt life or overload blower and motor

bearings, shortening their life expectancy. A belt tensioned too tightly can overload the motor electrically,

causing nuisance tripping of the motor overloads and/or motor failure and/or shaft failure.

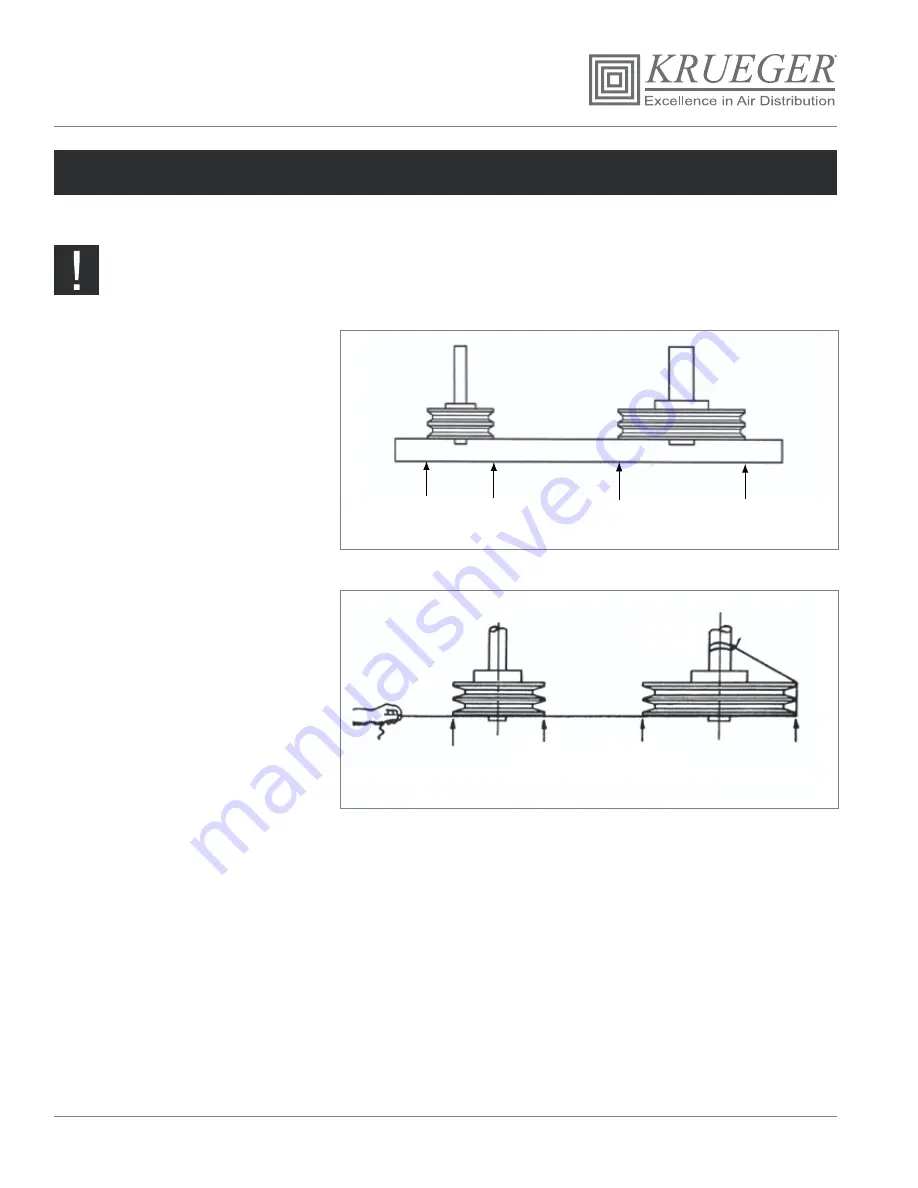

FIGURE 39 - ALIGNMENT USING STRAIGHT EDGE

Straight Edge Touching Sheaves At Points Indicated By Arrows

ALIGNMENT USING STRAIGHT EDGE

FIGURE 40 - ALIGNMENT USING STRING

Cord Touching Sheaves At points Indicated By Arrows

ALIGNMENT USING STRING

Cord Tied To Shaft

Sheave alignment and parallelism

of shafts is very important. Proper

alignment helps equalize the load across

the entire belt width, thereby reducing

wear and extending belt life. Figure 39

(right) shows how to align a synchronous

drive properly using a straightedge or

shows how to use a piece of string as

shown in Figure 40 (right).

After aligning the sheaves, check the

rigidity of the supporting framework.

Shafts should be well supported to

prevent distortion and a resulting change

in the center distance under load. Do not

use spring-loaded or weighted idlers.

Using a Straightedge

Place a straightedge against the outer

edge of the sheaves. Figure 39 (right)

shows the four points where the straight

edge should touch the sheaves. The

straight edge should cross the sheaves

at the widest possible part of the sheave.

Using a String

Tie a string around either shaft and pull it

around and across the outer edge of both

sheaves as shown in Figure 40 (right)

shows how the string should touch four

points when the drive is properly aligned.

If alignment is different than described,

refer to Sheave Replacement and

Adjustment later in this section.