42

Instruction manual SMV 10 600B – 60 1500B Publ. no. 6196.082 1117, Version 02

Service and maintenance

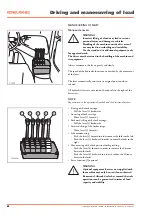

Measures when performing electrical welding

BE CAREFUL

It is important that these instructions are

adhered to when performing electrical welding

on the machine, or it can result in serious

damage of the machine. Battery cables must be

disconnected and all control units disconnected.

1. Remove the cables for the batteries and the alternator.

2.

Important!

Disconnect

all

control units in and on the

machine.

3. Connect the weld clamp to the component that is to be

welded and close to the area of the weld, never to the engine or

so that the electricity can go through a bearing.

When the welding is done, reconnect the cables to the alternator

and the control units before you reconnect the battery.

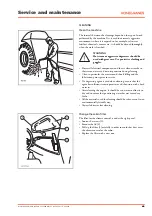

Correct procedure for jump-starting

BE CAREFUL

It is prohibited to jump-start using a quick-

charger, booster, power pack or similar. It may

cause power surges and serious damage to the

control units.

1. Connect the first cable from the positive pole on the starter

battery to the positive pole on the starter.

2. Then connect the second cable from the negative pole on the

starter battery to the chassis of the machine, e.g the fixing bolts

of the starter or a cross-beam near the starter.

3. When the engine has started: remove the cables in reverse

order.

Running-in/Service after the first 150 operating hours.

The machine may be run at full speed from the start. Consistent

maximum load of the hydraulic system and the transmission

should however be avoided during the first 50 hours of operation.

After the first 150 hours, a first service is performed in accordance

with the maintenance schedule.