-12-

Fig. 8

Fig. 9

1. Disassembly

• Remove Housing (C)

[48]

and magazine ass'y referring to page 9 to 10.

• For safety, push the valve core once more and check that compressed air is completely released and the

Piston Ass'y

[16]

is lowered to the bottom dead point referring to "Feeding compressed air" on page 29.

• Slide the Needle Cover

[43]

to the side of Pushing Lever (B)

[40]

and remove the Needle Roller D2.5

[41]

using a tapered tool.

NOTE: Pay attention not to drop the Needle Roller D2.5 [41] in the Housing Ass'y [50].

• Turn the Adjuster

[42]

and remove Pushing Lever (A)

[44]

, Probe

[45]

, and Needle Roller D3 x 10.4

[46]

.

• Remove the Needle Cover

[43]

from the Adjuster

[42]

.

2. Reassembly

Reverse the disassembly procedure to reassemble. Note the following points.

CAUTION: Adjustment of the Adjuster [42] is required when reassembling Pushing Lever (A) [44]. If

adjusted incorrectly, the nailer cannot drive nails or nails cannot be driven into the holes

of the metal connectors properly.

<Adjustment method of the Adjuster

[42]

>

• Mount the Needle Cover

[43]

to the Adjuster

[42]

. Slide the Needle Cover

[43]

to the side of Pushing Lever

(B)

[40]

without fitting in the groove.

• Make a gap about 4 mm between Pushing Lever (A)

[44]

and Adjuster

[42]

and align the groove of the

Adjuster

[42]

with the hole of Pushing lever (A)

[44]

(Fig. 10).

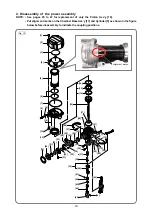

Disassembly and reassembly of the probe and pushing lever (A)

[44]

[42]

[43]

[41]

[44]

[46]

[45]

[43]

[42]

Fig. 10

[42]

[43]

4 mm

[44]

[16]

Align the groove of the Adjuster

[42]

with

the hole of Pushing Lever (A)

[44]

.