-2-

Problem

Possible cause

(*: Most common cause)

Inspection method

Corrective action

1.

Nails

cannot be

driven.

• No compressed air in the

nailer

• Compressed air leak

• Fill up the nailer with

compressed air, leave the

nailer still for one day, and

then check the nailing work.

• Check the sealing surfaces,

X-rings, and O-rings inside

the cylinder, piston, chamber

cover, and chamber base for

flaws, unwanted objects, and

other failures.

• Supply compressed

air.

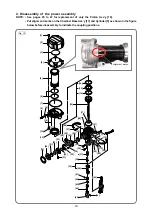

• Disassemble the

nailer and clean the

chamber, piston,

and their vicinity.

• Replace the sealing

parts.

2.

Nails are

driven but

bent.

*• Worn-out piston tip

*• Broken or worn-out blade

rack

• Check the piston tip for

excessive wear.

• Check the blade rack for

break or wear.

• Replace defective

parts. See page 25.

• Nails are not completely fed

into the injection port.

• Unspecified nails are used.

• Check whether the magazine

is correctly loaded with

specified nails.

• Use specified nails.

• Remove abnormal

nails and load the

nailer with proper

nails.

• Wood material too hard to be

nailed

• Drive nails into soft wood and

check whether the driven

nails are bent.

• This nailer is not for

hard wood.

• Deformed output section

• Check the tips of the pushing

lever, blade guide, nail

support, and probe for warp,

deformation and excessive

wear.

• Replace defective

parts.

• Probe is not set at the hole of

the metal connector.

• Set the probe at the hole of

the metal connector surely

and drive nail.

―

3.

Nails

cannot be

driven into

the

workpiece

completely:

the lower

heads

cannot be

made flush

with the

workpiece

surface.

• Worn-out piston tip

• Check the piston tip for

excessive wear.

• Replace defective

parts. See page 25.

*• Worn-out piston rack

• Check the piston rack for

excessive wear.

• Replace defective

parts. See page 25.

• Wood material too hard to be

nailed

• Drive nails into soft wood and

check whether the nail heads

are lifted.

• This nailer is not for

hard wood.

• Weak thrusting force against

wood to be nailed

• Firmly thrust the nailer

against wood to be nailed

and start nailing. Check

whether the nail heads are

still lifted.

• Follow the nailer

operation guide.

• Deformed output section

• Check the nail guide groove

of the pushing lever, blade

guide, nail support, and

probe for any trouble (e.g.,

deformation, excessive wear,

burrs).

• Replace defective

parts.

• Insufficient grease on the

cylinder and piston section

• Check the greasing condition

of the cylinder and piston

section.

• Replenish grease.