-6-

Problem

Possible cause

(*: Most common cause)

Inspection method

Corrective action

8.

No nailing

operation

with the

orange LED

blinking.

*See page 7.

*• Broken movable part that

disabled nailing work.

• Check the movable part for

any trouble (e.g.,

deformation, break,

excessive wear).

• Replace defective

parts.

• Disconnected wiring and

stator

• Check the wires and sensor

assemblies for breaks or

disconnection.

• Check the conductivity of the

stator.

• Replace defective

parts.

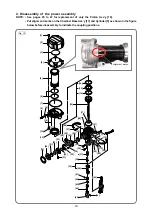

*• Power transmission

failure due to broken

gears

• Check that the gear turns

smoothly. See page 21.

• Check the gear box ass'y for

breaks.

• Replace defective

parts.

• Sensor (C) trouble

• Visually check the sensor

wires for breaks.

• Replace defective

parts.

• Excessively charged

compressed air

• Check the LED lighting

pattern.

• Move the piston down

to the bottom dead

point. Discharge the

compressed air. Use

the reduction valve

set to feed

compressed air again.

See pages 29 to 30.

9.

No nailing

operation

with the two

red LEDs

blinking

*• Overheat protector is

activated.

• Cool the nailer body and

check the nailing work.

―

*• Overcool protector is

activated.

• Warm the nailer body and

check the nailing work.

―

10.

No nailing

operation

with the one

red LED

blinking

*• Low battery voltage

• Use a fully charged battery

and check the nailing work

again.

• Charge or replace the

battery.

LED blinks in red.