- 14 -

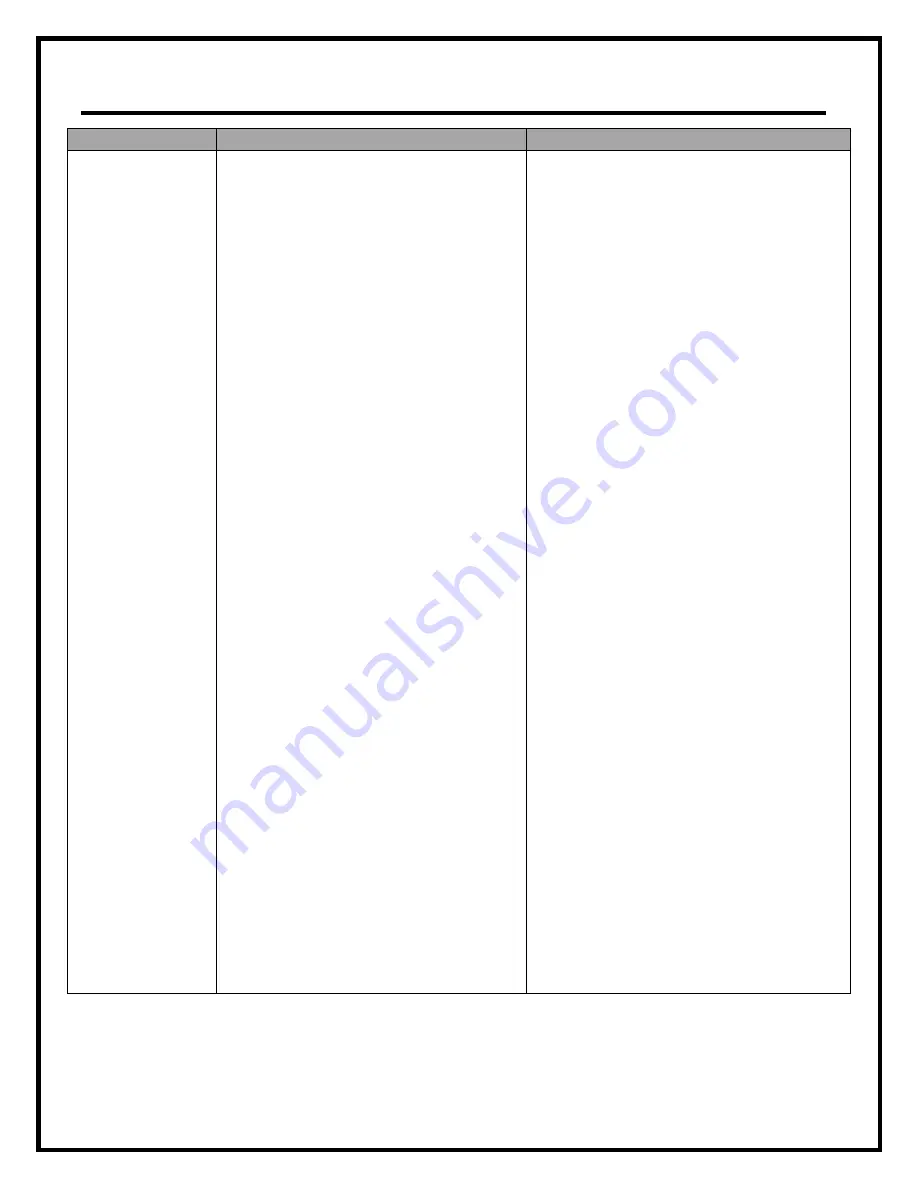

PROBLEM

POSSIBLE CAUSES

SOLUTION

Tool Won't Fire

1. No Klips in Magazine or last Klip on

Rack.

1. The Tool should NOT fire because

Sensor Shaft won’t allow the Safety to

disengage.

2. Door on Tool Nozzle is not fully closed

and locked.

2. Open and shut Door to make sure Door

Latch is locked.

3. Low air pressure at the Tool.

3. Check air supply to Tool. Make sure it is

at least 75 PSI (5.2 Bar) at the Tool.

Increase air pressure by 10 PSI (.69

Bar) increments up to a max of 110 PSI

(7.6 Bar).

4. O-Ring Seal on Tool's Piston is worn

or damaged.

4. Replace O-Ring on piston.

5. Trigger not functioning properly.

5. Inspect Trigger Assembly. Trigger may

not be functioning properly because of

dirt and debris in Assembly, wear to O-

rings [#205, #206, #209], or problems

with Secondary Trigger [#216]. Clean,

Repair or Replace.

6. Klips not feeding properly.

6. After checking that Klip Rack is full,

verify proper operation of Feeder.

Inspect for damage to Magazine [#445],

Hood [#446] or Stop Plate [#443] which

must be both working and in proper

position. Replace damaged parts.

7. Klips not in proper firing position.

Feeder not operating properly:

7. (a) Check air supply at Tool. Slow

recharge rate can be caused by

pressure drop. Make sure PSI is at least

75 PSI (5.2 Bar) at the Tool.

– OR –

(b) Inspect for defective / broken Feed

Spring [#441] or Push Spring [#437].

Replace damaged parts.

– OR –

(c) Sensor Shaft [#441] on Door not fully

dis-engaged. Check that Safety Unit is

functioning. Replace Safety Unit or

Sensor Shaft as required.

APPENDIX A: TROUBLESHOOTING

(con’t)

Summary of Contents for KTA-3 Series

Page 1: ...PN 10 00085 KTA 3 4 5 6 Series REBAR CONNECTOR TOOL OWNER OPERATOR MANUAL ...

Page 16: ... 16 APPENDIX B PARTS BREAKDOWN ...

Page 18: ... 18 ...

Page 20: ... 20 ...

Page 22: ... 22 ...

Page 24: ...PN 10 00085 ...