A-61096 June 1999

5-7

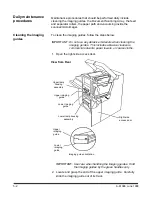

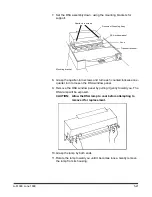

7. Grasp the rear document guide tabs.

Document Scanning Array

Roller

Rear document

guide tab

Feeder top cover

Rear document

guide tab

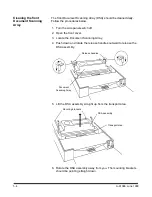

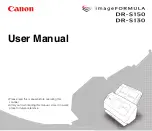

8. Remove the rear document guide by carefully guiding it between

the feeder top cover and the roller which is located in front of the

Document Scanning Array.

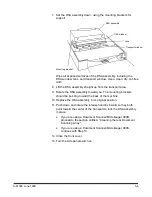

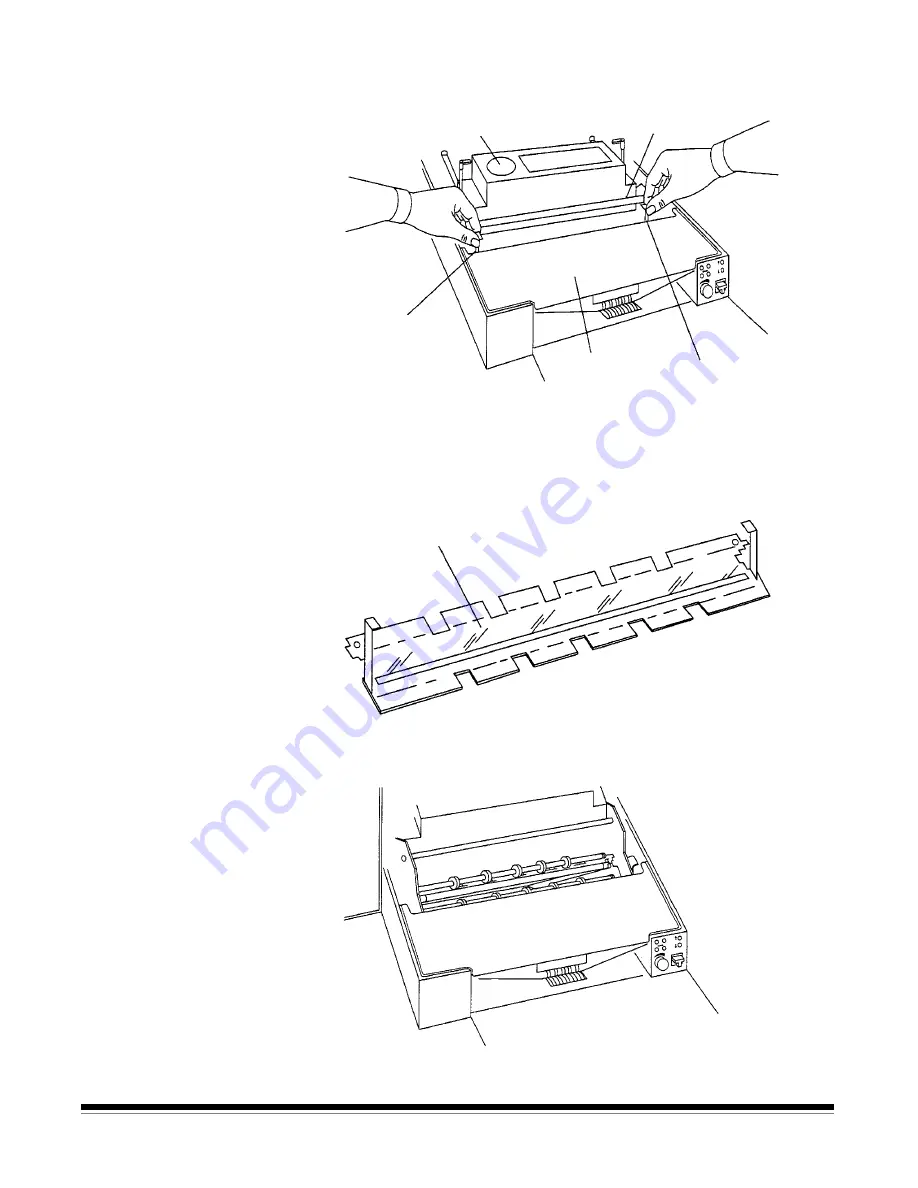

9. Wipe all exposed rear document guide surfaces, including both the

top and underside surfaces.

Rear document guide

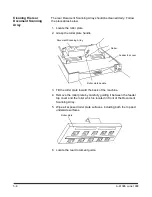

10. Wipe all inside surfaces exposed by removing the roller plate and

the rear document guide.