22.9

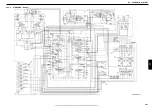

ARM CIRCUIT

This section describes the following operations.

(1) Arm in, light-load operating pilot circuit

(2) Arm in, light-load variable normal recirculation

main circuit / internal conflux main circuit

22.9.1

ARM IN, LIGHT-LOAD

OPERATING PILOT CIRCUIT

(1) Purpose:

Speed-up and Anticavitation when the arm is at

light loaded.

(2) Principle:

The oil returning from the arm cylinder rod (R) is

recirculated variably to the head (H) at arm 2

spool in C/V.

(3) Operation:

1.

When the arm in operation is performed, the

secondary pilot proportional pressure gets out of

port 7 of the left pilot valve (9) and acts upon the

low pressure sensor (SE-7).

At the same time, the pressure is branched off

in two flows, acts upon the Paa1 port and the

PLc2 port, changes over the arm spool and the

arm lock valve CRar. releases.

2.

The output voltage by the low pressure sensor is

input into mechatro controller, and is pilot

signal-processed, and is output to P1, P2 pump

proportional valve (PSV-P1), (PSV-P2) and arm 2

inverse proportional valve (PSV-A).

3.

The secondary pressure from pilot proportional

valve, which is reduced by arm 2 inverse

proportional valve (PSV-A) switches arm 2 spool.

22.9.2

ARM-IN, LIGHT-LOAD VARIABLE

NORMAL RECIRCULATION,

INTERNAL CONFLUX MAIN CIRCUIT

(1) Operation:

1.

The P2 pump delivery oil flows in travel left

section through P2 port of C/V (2) and is

branched off in by-pass circuit and parallel

circuit, but because arm 1 spool is switched, the

delivery oil which goes through parallel circuit

opens load check valve LCa and is flowed into

arm 1 spool.

2.

On the other hand, P1 pump delivery oil flows in

P1 port of C/V (2), and the flows in travel straight

section and travel right tandem path. Then

because arm 2 spool was switched, the delivery

oil opens load check valve LCAT2, goes through

arm 2 spool, and confluences with P2 pump

delivery oil in the valve section, and then is

flowed into arm cylinder head (H) side through Aa

port of C/V (2).

3.

The return oil from arm cylinder (R) side flows in

Ba port of C/V (2) and passes through the Ba

port because the arm lock valve CRar is open,

and is flowed into arm 2 spool through arm 1

spool.

4.

Because arm 2 spool is switched to normal

recirculation position, causing restriction of

passage to tank, the return oil from arm cylinder

(R) side flows into arm cylinder (H) side.

-Because, at light load, the pressure in cylinder

rod (R) side is higher than that in the head (H)

side, it opens the check valve housed-in arm 2

spool and is recirculated in the head (H) side,

resulting in the speed up of arm-in operation at

light load.

5.

Cavitations prevention control in arm-in operation

Command current is output to arm 2 solenoid

proportional valve by signal processing of E/G

speed and arm-in pilot pressure, accordingly the

arm 2 spool is switched to neutral (cavitations

prevention) position, resulting in cavitations

prevention.

Position of arm 2 spool

Reference:

In light-load arm-in operation (normal recirculation,

conflux), when the attachment to which the circuit in

P1 pump side is applied is operated, the meter-in

path of arm 2 spool is closed, resulting in single flow

operation.

[

22. HYDRAULIC SYSTEM

]

22-20

Copyright © 2015 Kobelco Construction Machinery Co.,Ltd. All rights reserved. [S5YN0046E03] [0109CsCshWbYs]