Set the time and

date

Setting the time and date requires entering Password 2 which is described in

the topic

Note:

If the AppStat is connected to a BACnet network that includes a time service

master, the time and date are automatically set to the network time and

date.

To change the schedule, see the procedure

Setting the occupancy schedule

.

Procedure

Steps

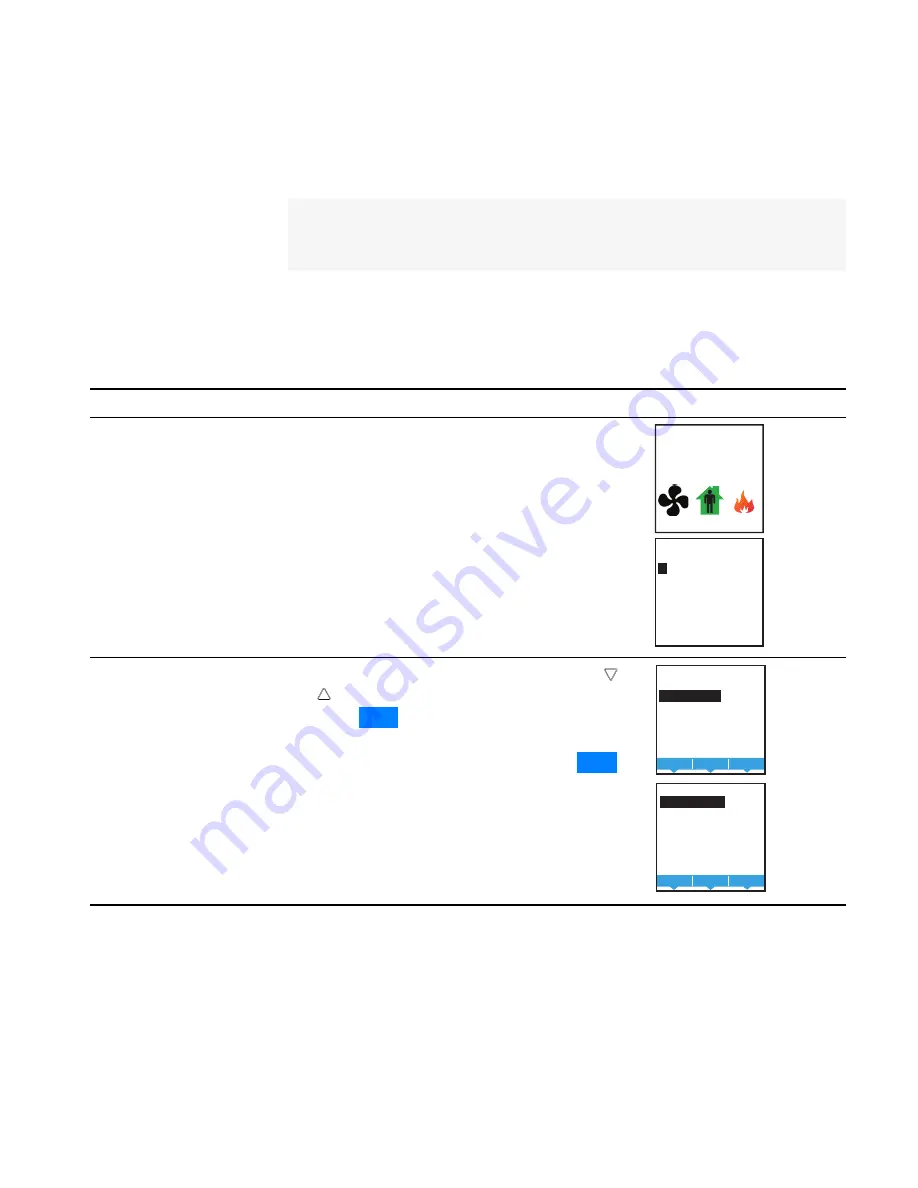

Display

1

Starting display

1.

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

F

°

70

AUTO

AUTO

SECURITY

ADMIN LEVEL

0

0 0 0

2

Select the

SCHEDULE menu.

1.

From the MAIN menu , press either the

or

button to select SCHEDULE.

2.

Press

Enter

. The SCHEDULE menu opens.

3.

Choose SET CLOCK and then press

Enter

.

The SET Clock menu opens.

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

Back

Enter

Exit

SCHEDULE

SET CLOCK

SETPOINT HOLD

ENTIRE WEEK

WEEKDAYS

WEEKEND

INDV DAYS

HOLIDAYS

Del

Enter

Exit

Set the time and date

Installation, Operation, and Application Guide for AppStat

Section 4: Commissioning functions

Revision G

45

Summary of Contents for BAC-4000 series

Page 6: ...Contents KMC Controls Inc 6 Revision G ...

Page 30: ...Section 2 Installing the AppStat KMC Controls Inc 30 Revision G ...

Page 64: ...Section 4 Commissioning functions KMC Controls Inc 64 Revision G ...

Page 112: ...Section 6 Application drawings KMC Controls Inc 112 Revision G ...

Page 124: ...Section 7 System integration KMC Controls Inc 124 Revision G ...

Page 128: ...power 28 roof top unit 98 rough in 18 Index KMC Controls Inc 128 Revision G ...