127

The temperature of condensate drainage water

is very low. If insulation is not enough, it shall

form dew and cause leakage to damage the

house decoration.

3

Insulation material selection for

drainage pipe

The insulation material should be flame

retardant material, the flame retardancy of

the material should be selected according

to the local law.

Thickness of insulation layer is usually

above 10mm.

Use specific glue to paste the seam of

insulation material, and then bind with

adhesive tape. The width of tape shall not

be less than 5cm. Make sure it is firm and

avoid dew.

4

Installation and highlights of insulation

construction

The single pipe should be insulated before

connecting to another pipe, the joint part

should be insulated after the drainage test.

There should be no insulation gap between

the insulation material.

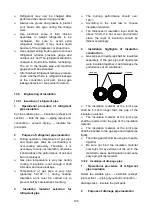

13.9 Engineering of electrical wiring

1

Highlights of electrical wiring

installation

All field wiring construction should be

finished by qualified electrician.

Air conditioning equipment should be

grounded according to the local electrical

regulations.

Current leakage protection switch should

be installed.

Do not connect the power wire to the

terminal of signal wire.

When power wire is parallel with signal wire,

put wires to their own wire tube and remain

at least 300mm gap.

According to table in indoor part named

“the specification of the power” to choose

the wiring, make sure the selected wiring

not small than the date showing in the

table.

Select different colors for different wire

according to relevant regulations.

Do not use metal wire tube at the place with

acid or alkali corrosion, adopt plastic wire

tube to replace it.

There must be not wire connect joint in the

wire tube If joint is a must, set a connection

box at the place.

The wiring with different voltage should not

be in one wire tube.

Ensure that the color of the wires of outdoor

and the terminal No. are same as those of

indoor unit respectively.

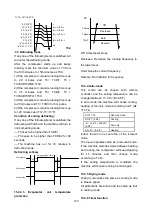

13.10 Test operation

1 The test operation must be carried out

after the entire installation has been

completed.

2

Please confirm the following points

before the test operation.

The indoor unit and outdoor unit are

installed properly.

Tubing and wiring are correctly completed.

The

refrigerant

pipe

system

is

leakage-checked.

The drainage is unimpeded.

The ground wiring is connected correctly.

The length of the tubing and the added

stow capacity of the refrigerant have been

recorded.

The power voltage fits the rated voltage of

the air conditioner.

There is no obstacle at the outlet and inlet

of the outdoor and indoor units.

The gas-side and liquid-side stop values

are both opened.

The air conditioner is pre-heated by turning

on the power.

3 Test operation

Set the air conditioner under the mode of

"COOLING" by remote controller, and check

the following points.

Indoor unit

Whether the switch on the remote controller

works well.

Whether the buttons on the remote

controller works well.

Whether the air flow louver moves

normally.

Whether the room temperature is adjusted

well.

Whether the indicator lights normally.

Whether the temporary buttons works well.

Summary of Contents for KDIP012-H2

Page 8: ...5 2 2 Part names of Indoor Outdoor units Cassette Units ...

Page 9: ...6 KDIR Duct Units ...

Page 10: ...7 KDIP Duct Units ...

Page 11: ...9 Ceiling floor Units ...

Page 12: ...10 HESP DUCT Units ...

Page 19: ...19 2 3 4 7 Outside Water Pump for Optional When Ceiling Installation ...

Page 31: ...33 KSIE024 H220 O KSIR036 H218 inch 37 2 16 1 31 9 40 6 26 5 15 9 ...

Page 34: ...36 Ceiling floor Units ...

Page 39: ...41 KTIR036 H2G1 KTIR048 H2G1 ...

Page 40: ...43 KUIR18 H2 KUIR24 H2 ...

Page 41: ...44 KFUF036 H2G1 KFUF048 H2G1 ...

Page 42: ...45 KFUF060 H2G1 ...

Page 43: ...46 KFUF036 H2G1 KFUF048 H2G1 ...

Page 44: ...47 KDIP090 H2 KDIP012 H2 KDIP018 H2 KDIP24 H2 ...

Page 69: ...74 6 2 Outdoor Unit KSIE018 H220 O KSIE024 H220 O ...

Page 70: ...75 KSIE009 H221 O KSIE012 H220 O ...

Page 71: ...77 KSIR036 H218 ...

Page 77: ...83 KDIR09 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 78: ...84 KDIR12 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 79: ...85 KDIR18 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 80: ...86 KDIR24 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 96: ...104 12 Field Wiring 9K 24K 36K 48K 60K ...

Page 97: ...105 ...

Page 147: ...155 P U P V ...

Page 148: ...156 P W P N ...

Page 181: ...191 4 Remove the evaporator fixing clamps to disassemble the evaporator Fixing clamps 1 screw ...

Page 188: ...221 5 Remove the four fixing screws of the fan motor then remove the motor 5 ...