GL0052-03

– Envireau Mono-Tech Rainwater – Installation & Operation Guidelines

Page 8

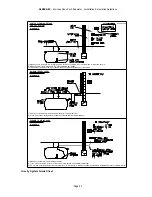

NO-MAINS SYSTEM INSTALLATION

Please refer to the

NO-MAINS SYSTEM Guide Sheet (at end of this section)

throughout these

instructions. Dispose of the instructions for other systems. As you are installing a

NO-MAINS

system it is

assumed that you have

no

MAINS WATER SUPPLY available, or you do not wish to use MAINS water in

this scheme. In all cases, this equipment should be installed by competent, qualified personnel and should

comply fully with all the relevant regulations, particularly the current Water Regulations and the current

edition of the IEE regulations concerning the safe installation of such equipment. BE SAFE.

It is assumed that you have read and understood the tank Installation Instructions, the Tank is IN SITU but

not backfilled, and you must now consider the installation of the pipework and cable runs. Please be aware

that there are connections to the pump and depth sensor, located in the tank, which must exit via the turret. If

you intend using extension rings on the tank turret please bear this in mind. If there is any doubt regarding

the ability to carry out these connections due to such extensions, you may need to consider an access

chamber. Consult with a qualified civil engineer in this circumstance, particularly regarding the surface

loading.

Study the NO-MAINS Guide Sheet and decide on the following:

1) The route by which you will take the surface drain pipes back to the tank from the gullies and whether you

are fitting a rainwater filter or not.

2) The route of your tank overflow pipe If you are not using the overflow it MUST be blanked off with a good

seal. (NOTE. IF YOU ARE FITTING A “PUMPED OVERFLOW” you should refer to the document on NON-

STANDARD SYSTEMS before proceeding.)

3) The route and inverts for pipework from any manifold chamber collection points or Rain Water Filters.

4) The Location of the Control Panel. Note that this unit should be mounted under cover, protected from frost,

and be located at a convenient height of between 1.5 metres and 2.4 metres above GROUND level. If you

wish to mount the unit in any other location please contact ENVIREAU for further advice.

The following instructions, up to and including Item (9) involve essentially Civil and Plumbing work.

The ELECTRICAL INSTALLATION begins at Item (10)

Once you are confident in your choice of locations you should begin by laying in the pipework and electrical

ducts as shown on the Guide Sheet. The collection pipes should be a minimum of 110mm and should be

connected to the roof drainpipes via sealed gullies, which prevent the ingress of surface water.

WARNING. Surface water can contain many contaminants and the system will not function correctly

with contaminated water. Keep your installation clean, particularly the tank, to avoid blocked filters

and valves etc.

You may be forced by site conditions to install pipework in a different order to that suggested below, but for

the sake of clarity the instructions follow the Guide Sheet sequence. The first stage is to install the pump

plumbing pipework.

NOTE. You are strongly advised to leave the INSTALLATION of the pump itself until you are ready to

electrically

connect it in to the CONTROL PANEL. See step (13) following.

5)

Refer to the Guide Sheet DIAGRAM A.

The

pump outlet

source is the

tank connector

supplied with the

tank. Make certain that it is securely tightened in to the tank turret. Cut the MDPE 25mm (black) pipe

squarely and clean off rough edges. Use an insert in the end of the pipe if recommended by the supplier.

Make sure that the pipe and tank connector are clean and free from grit and soil etc. Do not insert the pipe if

the portion to be inserted is badly scratched or striated. With the collet loose on the tank connector, insert the

pipe fully home then tighten the collet. Once tightened, check the fitting nut, tank side, for tightness. (Do not

over tighten.)

6)

Refer to the Guide Sheet DIAGRAM A

. Lay in the

MDPE pump outlet pipe

according to your chosen route

and ensure that bending radii are kept as large as possible to avoid kinking. Before terminating the pipe in

the building, wash it through to void any grit or small stones. Fix and secure to a stop-cock or isolating valve

close to, or convenient for connection to, the Control Panel. The next stage is the fitting of the Electrical Duct.

7)

Refer to the Guide Sheet DIAGRAM A.

The

Electrical Duct

should be 40mm PVC and should be suitable

for the purpose. The duct should enter the tank turret through the pre-drilled hole. If this hole is not