KisanKraft

TM

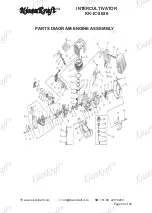

INTERCULTIVATOR

KK-IC-8626

: www.kisankraft.com

: +91.80. 22178200

Page 21 of 48

When checking the machine to make sure that it is okay before using it, check

the area around the muffler and remove any debris. Failing to do so could cause

the muffler to become overheated, and that this in turn could cause the engine to

catch on fire. Always make sure that the muffler is clean and free of debris before

use.

Check the intake air cooling vent and the area around the cylinder cooling fins

after every 25 hours of use for blockage. Note that it is necessary to remove the

engine cover in order to view the upper part of the cylinder.

Procedures to be performed after Every 100 Hours of Use:

1. Remove the muffler, insert a screwdriver into the vent, and wipe away any carbon

buildup. Wipe away any carbon buildup on the muffler exhaust vent and cylinder

exhaust port at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has worked its way in between the clutch lining

and drum, and if it has, wipe it away using oil-free, lead-free gasoline.

Intake Air Cooling Vent

Maintenance (Engine)

System/

Component

Procedure

Before

Use

Every

25

Hours

Every

50

Hours

Every

100

Hours

Note

Fuel Leaks,

Fuel Spillage Wipe out

Fuel Tank,

Air Filter,

Fuel Filter

Inspect,

clean

Replace the

Necessary

components

Idle

Adjusting

Screw

see

Adjusting

Idling Speed

Replace

carburetor if

necessary

Spark Plug

Clean and

readjust plug

gap

GAP:0.6 -

0.7mm

replace

spark plug

if necessary

Cylinder

Fins, Intake

Clean