5 Maintenance

■

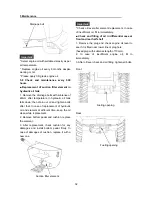

Replacement of hydraulic oil in working oil

tank

(

Replace it after 500h for initial use

)

1. Remove oil drainage bolt at bottom of oil tank

and drain out oil. After that, tighten the plug.

(hexed bolt with subtense length of 22mm)

2. Remove air filter at filling opening, check oil

level and fill in certain hydraulic working oil.

3. After oil filling, tighten plug of filling opening.

Keep the engine running at low speed, put front

and rear operation rod to “Neutral position”,

operate parking switch between

ON

←→

OFF

for

2~3 times;

keep circulating work of working part

and driving part of shovel for about 5 minutes and

then stop the engine, and make sure oil level with

oil gauge. In case of overfull or insufficient oil,

check with oil gauge and adjust it, ensuring oil

level is about 50L.

hydraulic air filter Fueling opening

Liquid level and oil temperature gauge

Drainage bolt

Important

* In case of sediment in oil tank, clean up

carefully.

* Prevent any impurities from entering oil tank.

Supplementary

:

Check oil level as per following standard because

hydraulic oil level may change with oil

temperature.

Oil level is close to the middle of oil gauge before

running (oil temperature 10

~

30 ).

℃

Oil level is above upper limit of oil gauge when

normal working (oil temperature 50

~

80 ).

℃

5.10 Maintenance every 1000 hours or one

year

■

Replacement of element of air filter

Open engine cover, remove dust shield, loosen

butterfly nuts and take out element; replace it and

then reassemble.

5.11 Check and repair once every 2000 hours

Carry out the following inspection and

maintenance every 50h, 200h, 250h, 500h and

1000h.

■

Check of DC generator and battery motor

Carry out check and maintenance of every 2000h.

Bushes are worn after 2000h, ask designated

service company to repair. Incorrect disassembly

of the machine may damage water-proofing

device. So ask special company to do so. In case

of working at night with frequent use of lamps,

check the lamps every 1000h.

5.12 Check and repair once every two years

■

Check and replace of pipes

Fuel pips or hydraulic rubber pipes are wearing

parts, even not use. Replace them after two years

or any wearing.

1. Check pipes or tighten any loosened or

damaged ring clamp often.

2. Exhaust air when replacing fuel pipe.

Important

* Prevent waste into pipes or spraying pump

during replacement. Otherwise, abnormity of

spraying pump may occur.

■

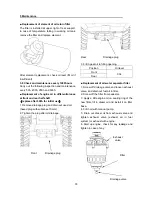

Replacement of radiator pipe

Change radiator pipe and ring clamp every two

years. In case of any expansion or stiffening or

cracks within two years, replace it immediately.

■

Replacement of cooling water

(

if long-term storage coolant is used

)

1. Open plug at bottom of radiator and drain out

cooling water.

2. Remove pipes at bottom of spare case and

drain out water in the case.

3. Fill in cooling water through filling opening of

radiator, open the plug and drain out water. Keep

draining until clean water flows out from plug cock.

34

Summary of Contents for KDD03

Page 2: ......