3 Operation of components

3. Operation of components

3.1 Safety components

▅

Start the engine at the neutral position

It is the safety component to avoid the sudden

start of loader when engine starts. It is allowed

to start the engine only when forward and

backward operating lever are at the neutral

position. Return the operating lever to the

neutral position in order to disconnect the loader

with engine after parking.

▅

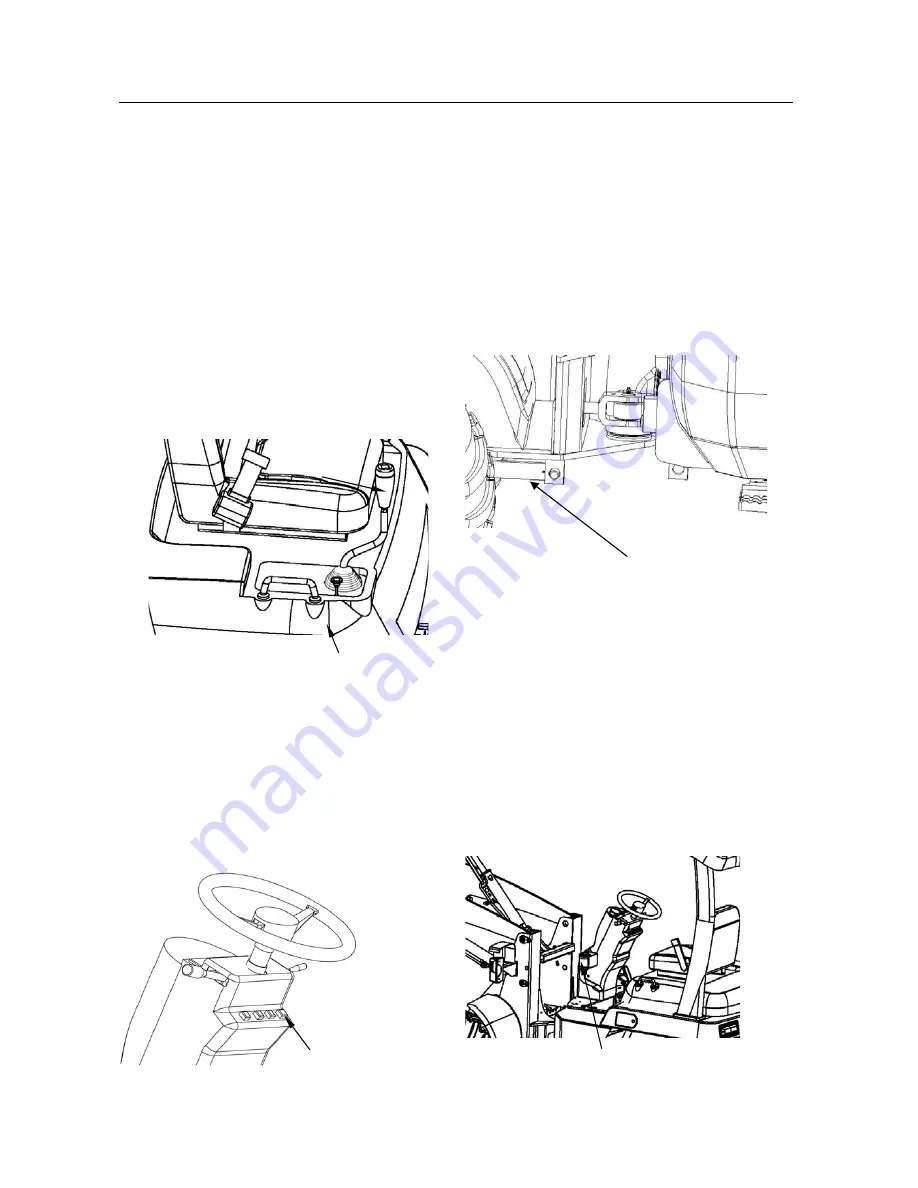

Lock button of operating lever of bucket

It is used to lock the operating lever of bucket.

Place the operating lever of bucket to the

neutral position and enter down the lock button

to lock the operating lever.

Operating lever of bucket

▆

Stop brake

It is used to stop or park the loader. Stop brake

is activated by pressing down the button of stop

brake and alert indicator on the panel lights. It

is mainly used when loader is stopped, serviced

or transported or driver leaves the loader.

Take all required measures for stop brake.

Loader cannot start if stop button is not

released.

▅

Lock connection

It is used to lock the front and rear carriages to

avoid unintended turning of them during check,

maintenance and transportation. Mount it on

seats of front and rear carriages at the lower left

and fix it with split pin. Then front and rear

carriages are aligned. Remove the connection

lock before loader drives normally and hide it in the

front carriage. Drive with active lock connection

will invalidate the steering wheel and lead to risks.

Hidden space

▆

Support of lifting cylinder

It is used to support the moving arm during the

check on lifted moving arm. It aims to prevent the

descent of moving arm. It is hidden in the front

carriage.

[Handling]

1. Raise the lifting cylinder to top.

2. Stop the running engine and take away the start

key.

3. Raise the piston rod of cylinder to approach the

support.

4. Insert the pin to fix it.

5. Lower the moving arm slowly till no gap is left.

Operating lever

of bucket

10

Support device of lifting cylinder

Stop button

Summary of Contents for KDD03

Page 2: ......