5 Maintenance

Chapter 5 Maintenance

5.1 Check

In order to use this machine safely and prevent

any troubles, please carry out frequent check and

periodic maintenance before use. The time in this

instruction book is stipulated by manufacturer.

Therefore, your maintenance shall be subject to

this time point.

▆

General instruction for maintenance and

check

1. In case of any difficulties or confusion, please

consult your local distributor or appointed

company for detailed structural functions.

2. Clean up the vehicle for check any

abnormities. Particularly those grease filling parts

and engine oil gauge to prevent any impurities

from entering. And prevent water splashing on

electrical device.

3. Select clean place to check and replace

engine oil and apply clean containers to prevent

any impurites.

4. Park the vehicle at smooth ground, check its oil

level and fill in fuel. Please use the grease with

same brand name.

5. It’s dangerous to drain oil or water or replace

filter immediately after parking; so carry out these

after complete cooling. In case of cold engine oil,

warm up it slightly and then drain it out.

6. Carry out exhaust operation after replacement

of oil or filter element.

7. For filling opening with filter screen, do not

remove the screen and fill.

8. Clean up the used lubricant after filling. Any

sands or wastes adhered on machine may

accelerate wearing.

9. When carry out engine oil and filter

replacement, check drained oil and used filter for

any metal powders and impurities.

10. Please apply incombustible cleaning agent or

light oil for cleaning of parts.

▆

Safety precautions for maintenance

* Prevent poisoning of exhaust gas while the

motor is working indoor. Pay special attention to

ventilation measures.

* Do not carry out check or maintenance during

driving of vehicle or working of motor.

* Before check or maintenance, put front and rear

operation rod at [Neutral position] and parking

brake. Let the shovel contact with ground, and put

shovel control rod on [Neutral position] to stop

engine working. lock shovel control rod with

locking button and pull out the starting key.

* Lock connecting rod with connection device and

fix front support (front bridge) and rear support

(rear bridge).

* Install fixed cushion on wheel.

* Remove connection of battery joint while

carrying out check and maintenance of electrical

system.

* Do not use scrub tools instead of appropriate

ones.

* No smoking while check and maintenance of

fuel system of filling fuel.

* Keep cloth with grease and combustible oil at

safety place without smoke.

* Wear helmet, safety glasses, respirator and

other safety protection device as per check and

maintenance instruction.

5.2 Inspection before starting up

Carry out inspection of machine before starting up

to prevent any troubles.

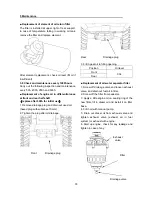

1. Walk around the vehicle and check for any

trails oil and water leakage. In case of any

leakage (joint of high-pressure pipe, hydraulic

cylinder and fuel system pipes), find out detailed

position and stop it. If still confusion, please ask

your local distributor or appointed service

company to do so.

2. Check all bolts and nuts for any loosen; if such

loosened parts are found, tighten it immediately

(particularly bolts of wheel hubs).

3. Check electrical wirings for any disconnection,

short circuits and loosened joints.

23

Summary of Contents for KDD03

Page 2: ......