18

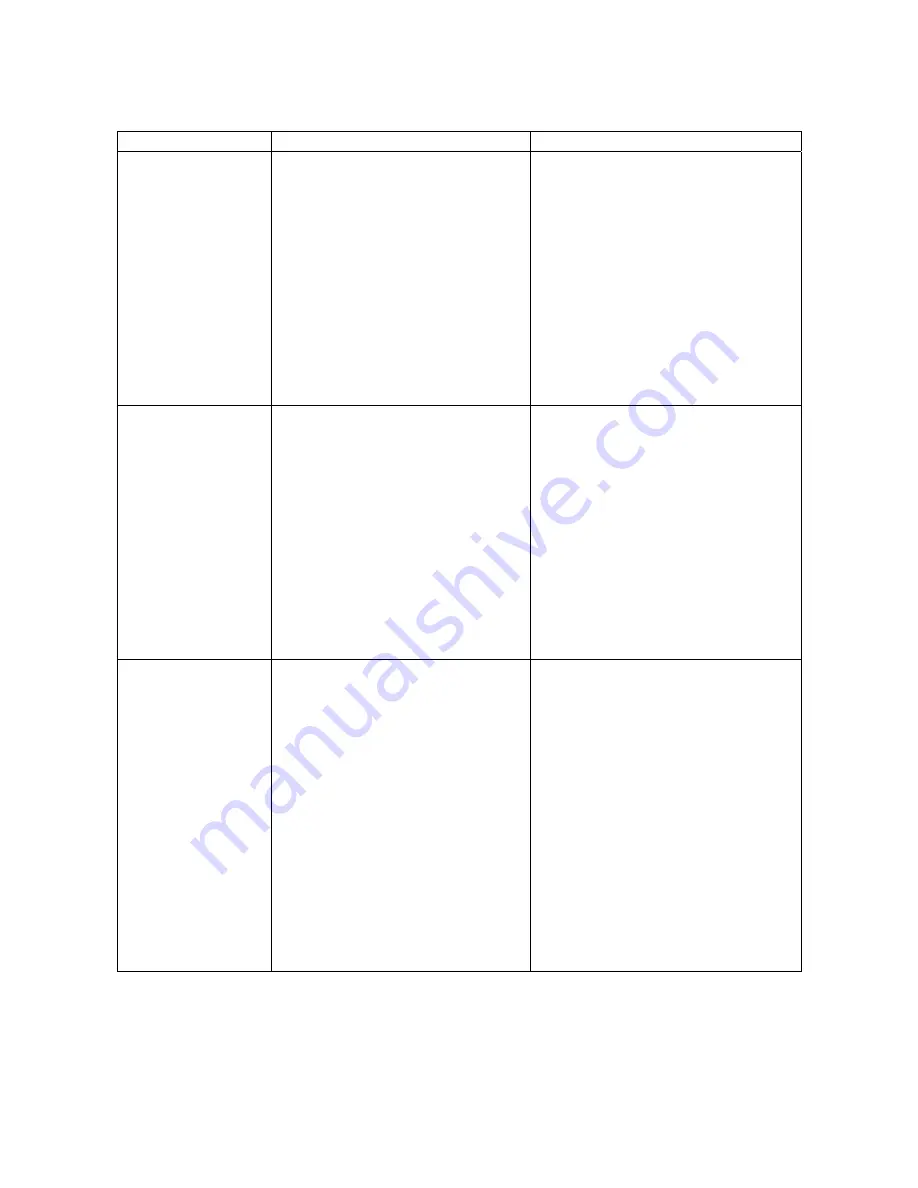

V (Welding problems and solutions)

(1) Welding

Problems Causes

Solutions

Surface damage

The shape of the welding head is

damaged.

The welding time is too long.

Bad bonding between the contact

surfaces of the welding head,

work-piece, and base.

Check the work-piece size.

Check the variation of the work-piece

between the molds.

Increase the pressure or amplitude to

reduce the welding time.

Adjust the buffer pressure.

Check if the welding head and base

are parallel.

Check the bonding between the

welding head and work-piece.

Check the bonding between the base

and work-piece.

Underlay the base, if required.

Burrs and flashes

over the joint face

The energy conducting point is too

big.

Deformation of the work-piece may

have a great effect.

The welding time is too long.

The thickness of the joint face is not

even.

The work-piece is too tight.

Reduce the size of the energy

conducting point.

Decrease the welding time.

Decrease the pressure.

Decrease the effect of the

deformation.

Decrease the welding time.

Re-design the joint face.

Check the operation conditions.

Reduce the bonding of the

work-piece.

Reduce The tolerance of the

work-piece.

The work-piece can’t

be aligned after

welding.

When assembling, the work-piece is

not aligned.

The base has improper support.

The sidewall bends.

Bad design of the energy conducting

point.

Tolerance of the work-piece is too

high.

Add a stud between two work-pieces.

If possible, design a new gauge for

correction.

Re-design an appropriate support.

Underlay the base.

Add hard supports if the bakelite plate

tilts.

Add ribs to the sidewall of the

work-piece.

Add hard supports if the bakelite plate

tilts.

Re-design the energy conducting

point.

Reduce the tolerance of the

work-piece.

Check the operation conditions.