– 11 –

❷

❶

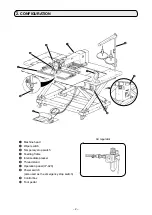

4-6. Adjusting the thread tension

If thread tension controller No. 1

❶

is turned

clockwise, the length of remaining thread on the

needle after thread trimming will be shorter. If it is

turned counterclockwise, the length will be longer.

Shorten the length to an extent that the thread is

not slipped off.

Adjust needle thread tension from the operation

panel and bobbin thread tension with

❷

.

Longer

Shorter

[Adjusting the needle thread tension]

1) Select THREAD TENSION button

A

in the sewing screen.

2) Set needle thread tension

with SCROLL

button

B

. There is a setting range of 0

to 200. When the set value is increased,

the tension becomes higher.

* When the set value is 50 at the time of

standard delivery, the thread tension is

adjusted to 2.35N (spun thread #50).

(When thread tension No. 1 is released)

4-7. Intermediate presser height

Press INTERMEDIATE PRESSER SET-

TING button

A

and adjust with TEN keys

B

so that the clearance between the

bottom end of intermediate presser and the

cloth is 0.5 mm (thickness of thread used).

1. Setting range of the intermediate presser is up to the standard of 3.5 mm.

However, the setting range can be changed up to max. 7 mm with memory switch U112.

2. When increasing the height of intermediate presser or making the needle size thicker, con-

firm the clearance between the wiper and the components. Wiper cannot be used unless

the clearance is secured. Turn OFF the wiper switch. Besides, note that the wiper is set so

as to sweep at the position where the intermediate presser is in the lowest position in spite

of the setting of intermediate presser height at the time of delivery. (Memory switch U105)

When raising the intermediate presser height, turn the pulley by hand to lower the needle bar,

and confirm that the needle bar does not interfere with the intermediate presser.

0.5 mm

B

A

B

A

B