6

INSTALLATION WIRING

Typical wiring diagrams are shown on pages 7-8.

Actual wiring should follow the print supplied with

the actuator

.

The wiring diagram shows the fundamental connec-

tions for the standard three-wire reversible single-

phase motor, and the standard permanent magnet dc

motor. These units show an arrangement with torque

switches, four limit switches, two feedback potentiom-

eters, and a heater. To meet special requirements,

certain items shown may not be supplied.

In all

instances the wiring diagram appropriate to the

equipment will be supplied with each unit

.

A barrier type terminal strip is located under the rear

cover opposite the output shaft. Two conduit entries

are located in the side of the unit to accommodate

standard 1 inch N.P.T. and inch N.P.T. fittings.

CAUTION: On standard single-phase wiring, the

position limit switches and the torque switches are

wired directly in the motor circuit and protect it at the

extremes of travel or at torque cutout. Three phase AC

or DC units must have these torque and position limit

switches wired into the controlling device to cause

end of travel or torque shutdown. Care must be taken

in wiring these to the controlling device so that the

appropriate direction of control is turned off when

that directions limit switch is actuated. If care is not

taken in phasing the equipment, damage may occur to

the actuator or driven load. Also, inductive devices,

such as lights and solenoids, must not be paralleled

across motor terminals 1 and 2 or 1 and 3 as this will

upset the motor capacitor phase shift and motor

torque will be lost.

All wiring should be done in accordance with pre-

vailing codes by qualified personnel.

Fusing must be installed in line power, and should be

of the slow blow type.

Wiring should be routed to the actuator through the

two conduit openings. Generally, one conduit will

contain input power and earth ground wires. The

other conduit would then contain low level input

and output signal wiring. It is required that all low

level signal wiring be a shielded type with the shield

grounded at source common.

After installation, it is required that all conduits be

sealed to prevent water damage and to maintain

NEMA 4 enclosure and applicable dust ignition

ratings.

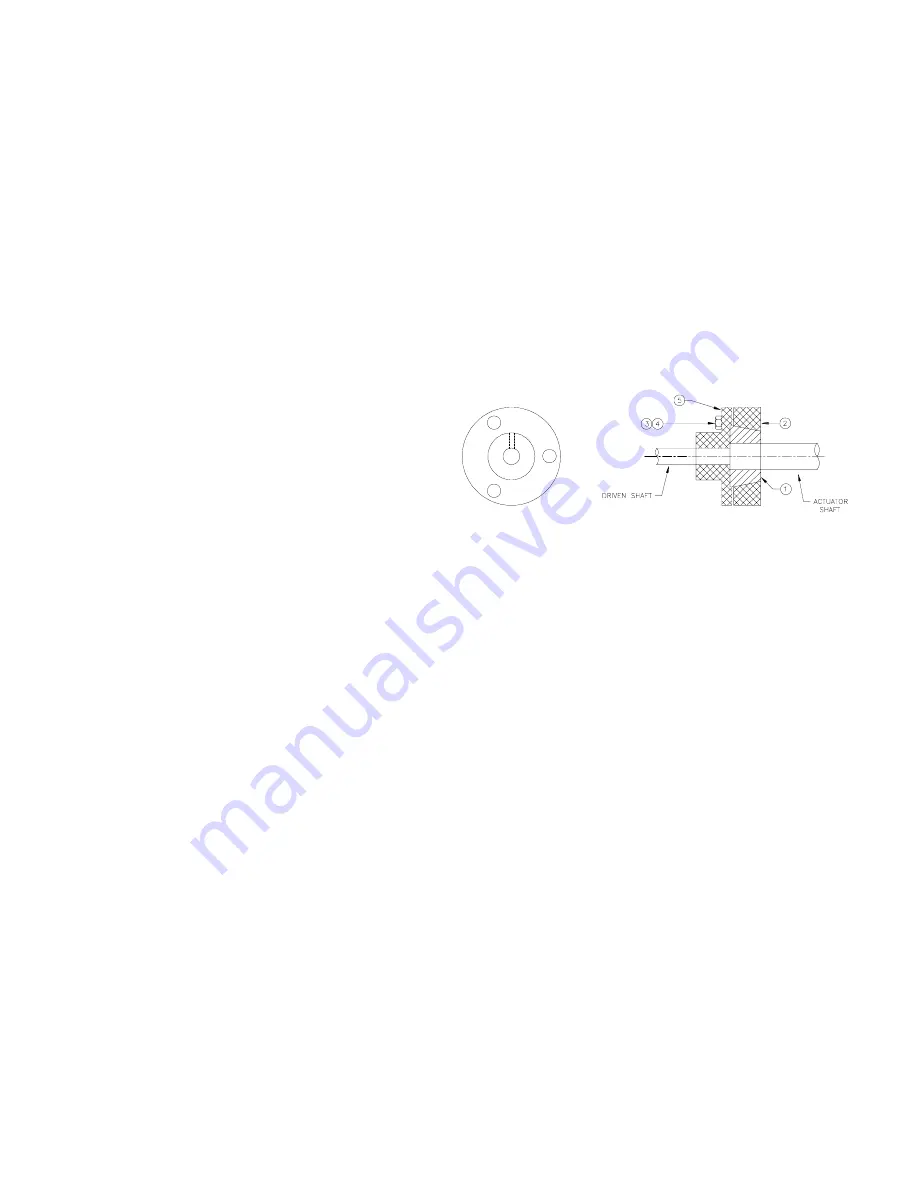

JORDAN CONTROLS SUPPLIED (OPTIONAL)

COUPLING (Field Installed)

Jordan Controls has designed a three piece wedge-

lock coupling which can be adjusted to align the

driven device to the actuator output shaft with no

concern as to keyway alignment of the shaft on the

drive device in relation to the spline on the actuator

output shaft.

ADJUSTMENT

1. Slide coupling (5) onto driven shaft.

2. Slide coupling cone (1) and cup (2) onto actuator

shaft.

3. Mount actuator with the two shafts in line and the

shaft ends about inch (3 mm) apart.

4. Turn the shaft of the driven device to the close

position.

5. Run the actuator to the close limit switch.

6. Lock coupling (5) to the driven shaft by pinning or

other suitable method.

7. Slide cone (1) to fit flat in recess of coupling (5).

8. Install three bolts and lockwasher (3) and (4) and

tighten. (20-30 ft. lbs.)

9. Operate the actuator in the open direction and

back to the close direction until the close limit

switch stops the actuator.

10. If the driven shaft does not move to the exact close

position you want, loosen the three bolts and turn

the driven shaft. Tighten the bolts. (20-30 ft. lbs.)

NOTE: Keep the coupling parts clean while

assembling.

See page 21 of this manual for Jordan supplied linkage

components information.

Installation

Summary of Contents for SM-1715

Page 23: ...23...