10

For the unit to function optimally, the 4mA end of the

feedback potentiometer must be preset to 50 ohms.

1. Position the actuator to the desired 4mA setting.

2. With potentiometer resistance at 50 ohms, adjust

ELEVATION for 4.0mA output.

3. Position the actuator to the desired 20mA setting.

4. Adjust RANGE for 20mA output.

5. Repeat steps 1 through 4 until desired accuracy is

achieved.

6. To reverse the 4 and 20mA output, interchange the BLUE

and YELLOW wires and return to step 1.

D. ACTUATOR WITH INTEGRAL AD-8130

SERVO AMPLIFIERS

Switch and feedback potentiometer alignment is accom-

plished in the same manner as actuator without amplifiers,

except motor power is supplied from the amplifier. Varying

the command signal input to the amplifier will allow reversal

of the rotation of the actuator output shaft to run to the

minimum/maximum switch settings. If the actuator does not

run to the limit switch, but stops short, the amplifier has

nulled and adjustments of span, elevation, loss of signal, or

feedback potentiometer may be required. Refer to IM-0607

for information on the AD-8130 amplifier.

The EC-10852 is for use with the AD-8130 servo amplifier

with LVDT (voltage feedback). The EC-10852 is used as the

HI and LO trim for the AD-8130. The AD-8130 is factory set

for operation with the EC-10852.

CAUTION: It is impor-

tant not to adjust the HI and LO trim on the AD-8130,

which are torque sealed at the factory

. For specific Setup

information and calibration, refer to the wiring diagram

supplied with your unit.

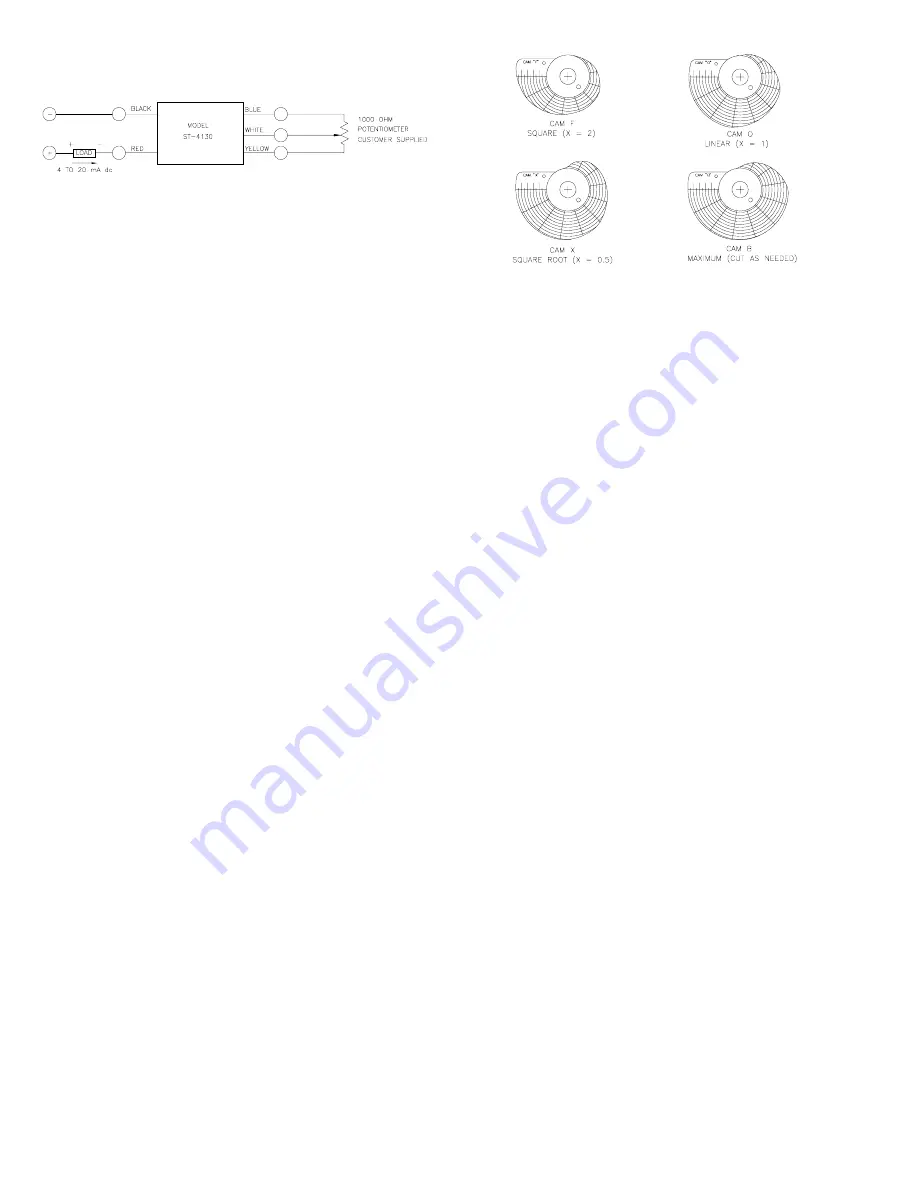

E. CHARACTERIZED CAM ADJUSTMENT

(OPTION)

The characterized feedback assembly is an option which

directly replaces the standard linear feedback potentiometer.

Prior to adjusting the cam, the end of travel limit

switches must be set and the proper cam installed for

your particular system requirements on the characterized

cam shaft. Four different cams are supplied with each

characterized assembly. The cams are printed on both

sides and may be flipped over to reverse the character-

ization action in relation to the output shaft rotation.

The cams are each printed with a letter O, F, or B

which indicate the cam type. Three of the cams are shaped

to correspond to X=2, 1, and 0.5 respectively in the equa-

tion:

% amplifier input = (% shaft rotation)x

The fourth cam is used for any value of x between 0.5 and 2

and must be cut by the user. For details on cutting this cam,

see To Shape Feedback Cam.

a. Run the actuator to the zero or minimum position limit.

While running, observe the direction of character cam

rotation.

b. Is the cam rotating in the direction of 100-0 for your

system requirement? If not, remove the thumb screw and

flip the cam over. Tighten the screw.

c. Have you selected the proper cam for the system require-

ment? If not, remove the thumb screw and change the

cam, installing the cam the same as in (b) above. (Green

or Black side up.)

d. Loosen three screws and remove the cam assembly.

e. Rotate the cam until the zero on the cam is in line with

the center line of the potentiometer or LVDT shaft.

f. Potentiometers need no further adjustment.

g. LVDT contactless feedback may require fine zeroing.

i. Apply power to the LVDT and monitor the output

with a volt meter.

ii. Loosen the two body clamp screws and slide the

body of the LVDT to obtain zero output.

iii. Tighten the body clamp screws.

iv. If a finer adjustment is desired, loosen the nut on

the LVDT shaft and turn the shaft slightly one

way or the other and tighten the nut.

TO SHAPE FEEDBACK CAM

With characterized feedback, one of the four cams supplied

(cam B), is partially shaped. For installation, it must be cut to

its final shape by the user. This cam is used if none of the

other three cams produces the desired input-output relation-

ship where:

% amplifier input = (% shaft position)X

Two typical conditions where the user might want to use the

fourth cam are:

1.In equation above, if the value of X is not equal to 0.5 or 2.

Summary of Contents for SM-1715

Page 23: ...23...