9

Start Up

ACTUATORS WITHOUT SERVO AMPLIFIERS

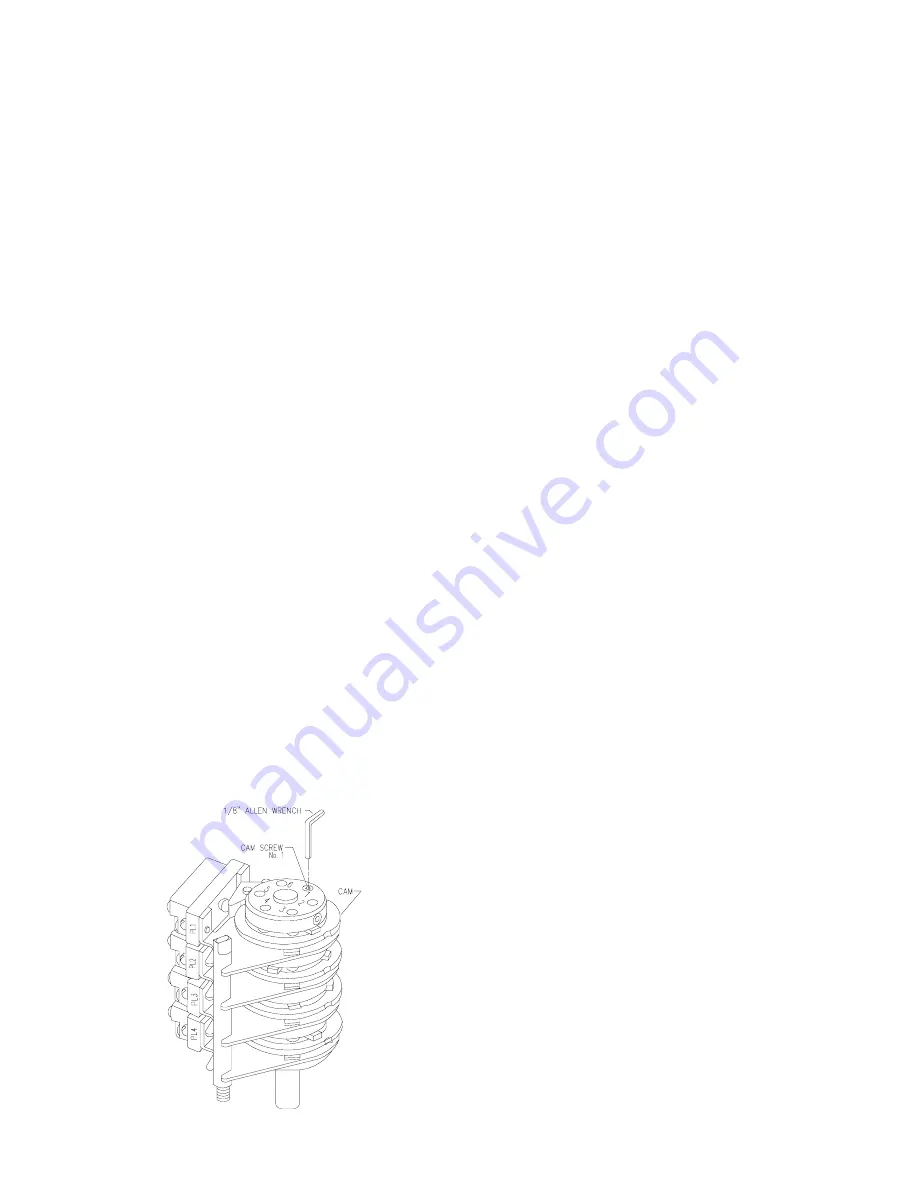

A. POSITION LIMIT SWITCH ADJUSTMENT

(Ref. Fig. 1)

NOTE:

The actuator is shipped in its mid-travel position.

1. Referring to your wiring diagram, apply motor power and

drive the actuator in the CW output shaft direction

(looking at the shaft), until PL1 trips and stops the

actuator. This is the CW limit switch setting and starting

point for final switch adjustment.

2. Move the controlled equipment to the same starting

point and couple the actuator output shaft to the driven

shaft.

3. Apply motor power to rotate the output shaft CCW about

5 degrees, allowing PL1 switch to reset.

4. Apply motor power to rotate the output shaft CW until

PL1 trips, turning off the motor. If the driven device is not

at the desired position:

a. Remove motor power.

b. Using an 1/8 inch, long shaft allen wrench,

loosen Cam Screw #1 about 1/4 turn.

c. Rotate Cam #1 CCW to allow the actuator to run

further in the CW direction or rotate the cam CW

to turn the actuator off sooner. (Cam #1 will turn

off the motor for CW output shaft rotation, when

the switch roller lever moves to the high side of

the cam with the cam rotating CW.)

d. Position the Cam as desired and while holding in

place, tighten screw #1 with moderate force to

adequately clamp the cam in place.

DO NOT OVER TIGHTEN.

5. Apply motor power to drive the actuator to the desired

CCW position or until PL2 trips and stops the motor. If

the driven device is not at the desired position:

a. Remove motor power.

b. Loosen Cam Screw #2 about a turn.

c. Rotate Cam #2 CW to increase the actuators

total travel range or CCW to decrease the travel

range.

d. Hold the cam in place and tighten screw #2.

6. Electrically operate the actuator to its CW limit and back

to the CCW limit to check switch settings. Readjust Cam

#1 or #2 as needed.

7. Switches 3 through 6 (optional) are adjusted by loosening

their respective cam screws and rotating the cam. They

may be set anywhere within the range of PL1 or PL2.

8. If the unit is equipped with a feedback device and

switches PL1 or PL2 were readjusted, proceed with the

proper feedback alignment prior to any further adjust-

ments or operation of the actuator.

B. 1000 OHM POTENTIOMETER ADJUSTMENT

1. Run the actuator to the center of travel. Loosen the three

panhead screws, securing the potentiometer body, and

rotate it to its center of travel (500 ohm) position. An

ohmmeter will be required for this adjustment. Tighten

the three screws.

2. Run the actuator to the zero or minimum travel limit.

With the actuator running, monitor the potentiometer

with an ohmmeter to ensure the potentiometer

deadband is not crossed.

3. If your system requires a low resistance starting point,

loosen the three screws and rotate the potentiometer

body for the required starting resistance. This is usually

20 to 50 ohms (measured from the potentiometer wiper

arm to the zero end of the potentiometer).

C. 4 to 20mA TRANSMITTER OPTION

ADJUSTMENT

The ST-4130 (1000 ohm-input, 4 to 20 mA output) two wire

transmitter modulates the current on a direct current supply

proportional to the input resistance. It is powered by a 12.0

to 36.0 Vdc regulated power supply line which is modulated

from 4 to 20 mA proportional to the resistance of the input.

Summary of Contents for SM-1715

Page 23: ...23...