5538117-UIM-B-0319

Johnson Controls Ducted Systems

13

SECTION VI: OPERATION

The following sequences of operation are based on using a single-

stage air conditioning thermostat.

COOLING SEQUENCE OF OPERATION

1.

On a call for cooling, the wall thermostat sends a 24V “Y” signal to

the unit. The unit contactor will close, which energizes the outdoor

fan and the compressor. The 24V signal is also sent to the indoor

blower motor, which will run at the selected cooling speed.

2.

When the demand for cooling has been satisfied, the wall thermo-

stat will remove the 24V “Y” signal from the unit. The contactor will

open and the outdoor fan and the compressor will stop. The indoor

blower has a built-in delay and will continue to run for 60 seconds

after the cooling signal has been removed.

HEATING SEQUENCE OF OPERATION

(for units that have an optional electric heat kit)

1.

On a call for heating, the wall thermostat sends a 24V “W” signal to

the unit. The indoor blower will then start to run at the selected heat-

ing speed. The 24V signal will also go to the sequencer(s) or relays

in the electric heat kit and will turn on the electric heating elements.

2.

When the demand for heating is removed, the wall thermostat will

remove the “W” signal. When the 24V signal is removed from the

electric heat sequencer, the heating elements will turn off. The

indoor blower will continue to run for 60 seconds after the call for

heat is removed.

Electric Heat Limit Switch Operation

6HK three phase heat kits utilize a normally closed low voltage limit

switch, normally closed line voltage limit switch, and a normally closed

fusible link. If the fusible link opens, it must be replaced with the appro-

priate OEM part and the cause must be investigated and corrected.

When the limit switch opens, the heating elements will turn off. The

indoor blower will continue to run. The limit switch will automatically

reset when the temperature has fallen to a normal level, at which time

the heating elements will be turned on again.

* Motor program has 60 second blower off delay on all 5 speed taps.

STARTUP

1.

Check the electrical supply voltage being supplied. Be sure that it is

within the specified range on the unit data plate.

2.

Make sure all electrical connections are tight.

3.

If unit is connected to 208 volt supply power, the control transformer

must be wired accordingly.

4.

Turn unit electrical power on.

5.

Set the room thermostat to COOL mode and lower the desired tem-

perature setting lower than the room temperature to create a call for

cooling.

6.

Measure the total system duct static and set the blower motor cool-

ing speed appropriately per airflow performance tables.

7.

If an optional electric heat kit was installed, make sure the “W”

blower speed is set at or above required speed. See Table 12.

8.

Make sure all units panels are in place and secured, and that an air

filter is installed.

Compressor Rotation

Three-phase, scroll compressors operate in only one direction. If the

scroll is drawing low amperage, has similar suction and discharge pres-

sures, or is producing a high noise level, the scroll is misphased.

If necessary, change the incoming line connection phasing to obtain the

proper rotation.

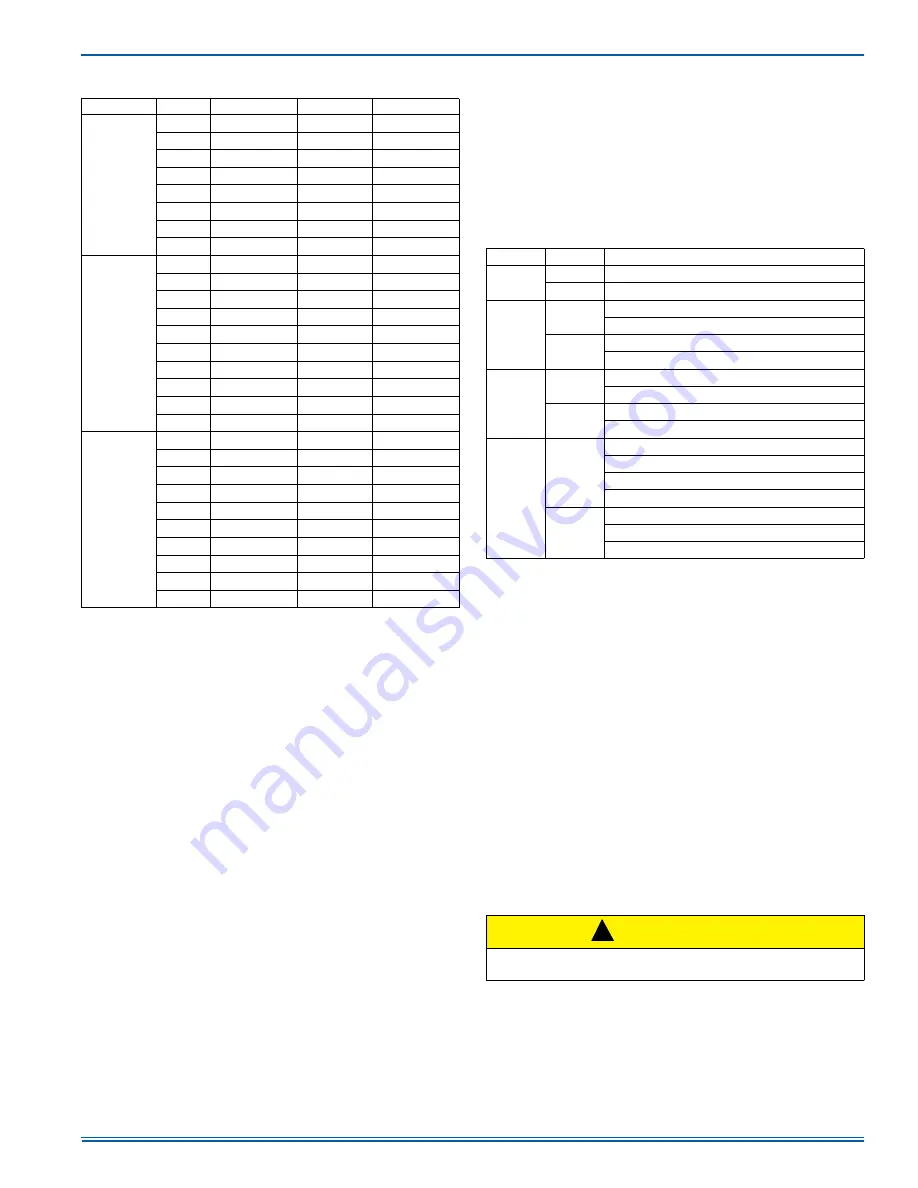

TABLE 14:

Additional Static Resistance

Size (Tons)

CFM

Wet Indoor Coil

Economizer

1

1. The pressure drop through the economizer is greater for 100% outdoor air

than for 100% return air. If the resistance of the return air duct is less than

0.25 IWG, the unit will deliver less CFM during full economizer operation.

Filter pressure drop based on standard filter media tested at velocities not

to exceed 300 ft/min.

Filter/Frame Kit

36 (3.0)

700

0.01

0.00

0.04

800

0.02

0.01

0.06

900

0.03

0.01

0.08

1000

0.04

0.01

0.10

1100

0.05

0.01

0.13

1200

0.06

0.02

0.16

1300

0.07

0.03

0.17

1400

0.08

0.04

0.18

48 (4.0)

1100

0.02

0.02

0.04

1200

0.03

0.02

0.04

1300

0.04

0.02

0.05

1400

0.05

0.03

0.05

1500

0.06

0.04

0.06

1600

0.07

0.04

0.07

1700

0.07

0.04

0.08

1800

0.08

0.04

0.09

1900

0.09

0.05

0.10

2000

0.09

0.05

0.11

60 (5.0)

1100

0.02

0.02

0.04

1200

0.03

0.02

0.04

1300

0.04

0.02

0.05

1400

0.05

0.03

0.05

1500

0.06

0.04

0.06

1600

0.07

0.04

0.07

1700

0.07

0.04

0.08

1800

0.08

0.04

0.09

1900

0.09

0.05

0.10

2000

0.09

0.05

0.11

TABLE 15:

Thermostat Signals

Signal

State

Function

G

ON

Indoor blower instant on

OFF

Indoor blower off after 60-second delay

W

ON

Indoor blower instant on

Electric heat stages on (if so equipped)

OFF

Electric heat stages off (if so equipped)

Indoor blower off after 60-second delay

G & W

ON

Indoor blower instant on in heating speed

Electric heat stages on (if so equipped)

W OFF

Electric heat stages off (if so equipped)

Indoor blower switches to continuous fan speed

G & Y

ON

Outdoor fan on

Indoor blower instant on in cooling speed

Compressor on

System operates in cooling mode

Y OFF

Compressor instant off

Outdoor fan instant off

Indoor blower switches to continuous fan speed

CAUTION

Scroll compressors require proper rotation to operate properly. Fail-

ure to check and correct rotation may result in property damage.

!