XL EVAPORATIVE COOLING PRODUCTS

INSTALLATION

S140-600 IOM (NOV 07)

Page 9

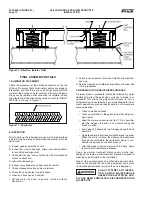

OPTIONAL VIBRATION ISOLATOR

MOUNTING INSTRUCTIONS

Vibration isolators, purchased as an option, are used to

minimize transfer of forces due to vibration/dynamic load-

ing to or from unit. To install the isolator feet and rails, refer

to Figure 9 and Figure 10 respectively and follow these

instructions:

ISOLATOR FEET

1.

Refer to the submitted foundation layout drawing for the

correct location of each isolator and support beams.

2.

Place the isolators in their proper location and attach the

bottom plate to the building support steel by means of bolt-

ing or welding.

3.

Set the unit support beams on top of the isolators and at-

tach them to the top plate by means of bolting or welding.

4.

Lower the fi rst section of the unit onto the beams, taking

care not to overload any one corner.

Do not attempt to move the unit

laterally with the weight on the

isolators. If it is necessary to move

the unit, remove the weight from the isolators by raising

the unit before moving. Failure to follow this procedure

could result in damage to the isolator.

5.

Attach the unit to the beam by means of bolting or

welding.

6.

Continue to attach the remaining unit sections per the

instructions on the previous pages and complete piping,

wiring,etc.

NOTE: Ridged connections between the unit and building

structure shall not be permitted when vibration isolators

are used. Use fl exible connections that allow for vibration

and noise isolation.

7.

Loosen the vertical restraint jam nuts to the end of the

restraint bolts.

8.

When the unit is completely installed and operating, turn

the leveling bolts counterclockwise several complete turns

on each isolator until the blocking channel can be removed

by hand. It will be necessary to alternate between isolators

in order to uniformly raise the unit. Do not attempt to place

all the weight on any one isolator, but distribute the load

proportionally.

9.

After the unit is level, tighten the vertical restraining nuts

fi nger tight, then back off one half turn. Lock each nut with

the jam nuts provided.

Figure 9 - Vibration Isolator Feet

ISOLATOR RAILS

1.

Refer to the submitted foundation layout drawing for the

correct location of each isolator rail.

2.

Place the isolator rail assemblies in their proper location

and attach the bottom plate to the building support steel by

means of bolting or welding.

3.

Lower the fi rst section of the unit onto the rails, taking care

not to overload any one corner.

Do not attempt to move the unit

laterally with the weight on the

isolators. If it is necessary to move

the unit, remove the weight from the isolators by raising

the unit before moving. Failure to follow this procedure

could result in damage to the isolator.

4.

Attach the unit to the isolator rail by means of bolting or

welding.

5.

Continue to attach the remaining unit sections per the

instructions on the following pages and complete piping,

wiring, etc.

NOTE: Ridged connections between the unit and build-

ing structure shall not be permitted when vibration

isolators are used. Use fl exible connections that allow

for vibration and noise isolation.

6.

Temporarily remove all vertical locknuts from hold-down

bolt.

7.

When the unit is completely installed and operating, turn

the leveling nuts clockwise several complete turns on each

isolator until the shim can be removed by hand. It will be

necessary to alternate on each isolator in order to uniformly

raise the unit. Do not attempt to place all the weight on any

one isolator, but distribute the load proportionally.

8.

After the unit is level, replace all vertical locknuts on hold-

down bolts and fasten fi nger tight.